Achieving the perfect edge on your culinary tools is an art, and central to this art is understanding the **sharpening angle for Japanese knives**. This critical parameter dictates not only how sharp your blade will become, but also its durability, cutting performance, and longevity. Japanese knives, with their renowned precision and exceptional sharpness, demand a nuanced approach to sharpening that respects their unique design and steel properties. Without the correct **sharpening angle for Japanese knives**, even the finest steel can underperform, leading to frustration and potential damage to these exquisite tools. Mastering this aspect of knife care is fundamental for anyone serious about maintaining the peak performance of their Japanese cutlery.

The Unseen Edge: Demystifying the Sharpening Angle for Japanese Knives

The allure of Japanese knives lies in their unparalleled cutting performance, a characteristic intimately tied to their exceptionally thin and sharp edges. This sharpness is not merely a product of superior steel or meticulous craftsmanship; it is fundamentally engineered through precise blade geometry and, crucially, the specific **sharpening angle for Japanese knives**. Unlike their Western counterparts, which often feature more robust, symmetrical edges designed for brute force and resilience, Japanese blades prioritize refined cutting efficiency. This difference necessitates a distinct approach to maintenance and sharpening, where the angle is not just a suggestion but a critical directive. Every degree of variation can profoundly impact how the knife slices through ingredients, its ability to hold an edge, and its overall lifespan. Therefore, demystifying this unseen edge is the first step toward true mastery of Japanese knife care.

The concept of an optimal **sharpening angle for Japanese knives** extends beyond a simple numerical value; it encompasses an understanding of the blade’s primary grind, the specific steel alloy, and its intended purpose. For instance, a delicate sashimi knife designed for slicing raw fish will demand a far more acute angle than a sturdy deba knife built for breaking down fish bones. Ignoring these inherent design philosophies during sharpening can lead to a compromised edge that is either too brittle for practical use or too obtuse to deliver the signature Japanese cutting experience. It’s a delicate balance, and achieving it requires both theoretical knowledge and practical skill. The pursuit of the ideal angle is what separates a merely sharp knife from a truly exceptional one, transforming a cutting tool into a seamless extension of the chef’s will.

Understanding the intricacies of the **sharpening angle for Japanese knives** also requires an appreciation for the traditional craftsmanship that goes into their creation. Many Japanese blades are handcrafted by artisans who spend years perfecting their techniques, including the precise geometry of the blade. When you sharpen such a knife, you are not just restoring its edge; you are engaging in a process that honors this tradition and preserves the knife’s inherent qualities. This deep connection between design, material, and sharpening technique is what makes the study of Japanese knives so fascinating and rewarding. It’s a journey into metallurgy, geometry, and craftsmanship, all converging on that one critical factor: the perfect edge angle.

Furthermore, the maintenance of the correct **sharpening angle for Japanese knives** directly influences the joy of cooking. A truly sharp knife reduces effort, minimizes ingredient bruising, and enhances precision in every cut. Imagine thinly slicing delicate vegetables for a stir-fry or effortlessly filleting a whole fish; these tasks become a pleasure rather than a chore. Conversely, a dull or improperly sharpened knife can lead to frustration, slipping, and even accidents. Thus, the emphasis on angle is not just for performance fanatics but for anyone who seeks to make their culinary experience safer, more efficient, and ultimately, more enjoyable. It’s an investment in both the tool and the craft.

The journey to mastering the **sharpening angle for Japanese knives** is continuous, involving patience, practice, and a willingness to learn from each sharpening session. It’s about developing a keen eye and a sensitive touch to feel the burr, understand the grind, and consistently apply the correct pressure and angle against the sharpening stone. This skill, once developed, empowers you to breathe new life into your knives, ensuring they always perform at their absolute best. It’s a testament to the idea that true craftsmanship extends beyond creation to the diligent and thoughtful maintenance of one’s tools, ensuring they are always ready for the demands of the kitchen.

The Precision Imperative of Japanese Blade Geometry

Japanese knives are renowned globally for their exceptional sharpness and cutting precision, attributes that stem directly from their sophisticated blade geometry. This geometry, meticulously crafted, dictates the ideal **sharpening angle for Japanese knives**. Unlike many Western knives that feature a robust, often symmetrical V-shaped edge with thicker blades, Japanese blades are typically much thinner behind the edge and often exhibit complex asymmetrical grinds. This thinness reduces resistance when cutting, allowing for incredibly clean and precise slices, essential for delicate tasks like sashimi preparation or fine vegetable work. The precision imperative isn’t just about the final edge; it’s about the entire cross-section of the blade, from spine to cutting edge.

The unique steel used in Japanese knives, often high-carbon steel hardened to a much higher Rockwell (HRC) scale than Western counterparts, contributes significantly to their ability to achieve and maintain such acute angles. While this harder steel allows for a finer edge, it also means the steel can be more brittle if the **sharpening angle for Japanese knives** is not meticulously maintained. A common characteristic is the “clamshell” or “hamaguri” grind, often seen on single-bevel knives. This convex grind transitions smoothly to the edge, providing support to a very acute angle, preventing chipping while still offering superior sharpness. Understanding these nuances is crucial, as attempting to apply a Western-style angle to a Japanese blade can compromise its integrity and performance.

Moreover, Japanese blade geometry often incorporates different facets and bevels that serve specific purposes. For example, a single-bevel knife (kataba) like a Yanagiba or Deba has a primary bevel on one side (omote) and a flat or slightly concave back (ura). This design allows for incredibly thin, precise cuts, but it also means the **sharpening angle for Japanese knives** on the primary bevel must be significantly steeper than a double-bevel knife, while the ura side requires only minimal flattening to remove a burr and ensure suction release. The interaction between these surfaces is what grants the knife its unique cutting action and demands a highly specialized sharpening technique that respects this inherent asymmetry. Ignoring this complexity can lead to an ineffective or damaged edge.

The precision imperative also extends to the subtle variations within double-bevel (ryoba) Japanese knives. While many Western-style Japanese knives like Gyuto or Santoku may appear similar to their European counterparts, their geometry is distinctly different. They typically feature thinner blades, often ground to very acute angles ranging from 10 to 15 degrees per side, compared to the 20-25 degrees per side common in Western knives. This smaller total included angle is what allows for their renowned sharpness. Furthermore, some Japanese double-bevel knives might still feature a slight asymmetry, with one side being sharpened at a slightly different angle or having a more pronounced primary bevel to optimize for right- or left-handed use. This subtle difference further underscores the need for a precise and informed approach to the **sharpening angle for Japanese knives**.

Ultimately, respecting the precision imperative of Japanese blade geometry means approaching sharpening not as a simple task but as a sophisticated craft. It requires an understanding of the blade’s intended function, its steel type, its grind, and its unique cultural heritage. Each Japanese knife tells a story through its form, and mastering its sharpening angle is a way of continuing that story, ensuring the blade performs as its makers intended. This deep respect for geometry is what unlocks the full potential of these magnificent cutting tools, allowing them to deliver unparalleled performance in the hands of a skilled user. The very essence of the **sharpening angle for Japanese knives** is embedded in this profound geometric precision.

Why Angle is Paramount: Beyond Just Sharpness

While sharpness is undoubtedly the most immediately apparent benefit of a well-sharpened knife, the correct **sharpening angle for Japanese knives** is paramount for reasons that extend far beyond simply achieving a keen edge. It fundamentally influences the knife’s durability, its specific cutting performance for various tasks, and its overall longevity. A knife can be razor-sharp but still perform poorly or chip easily if the angle is not optimized for its design and intended use. This holistic impact is why angle considerations are at the very heart of Japanese knife maintenance, moving beyond mere sharpness to a broader definition of edge quality and resilience.

Firstly, the chosen **sharpening angle for Japanese knives** directly affects edge durability. An angle that is too acute (too thin) for the steel type, blade geometry, or cutting task can result in an edge that is prone to chipping or rolling. High-carbon, high-hardness Japanese steels, while capable of holding incredibly fine edges, can be brittle if unsupported. Conversely, an angle that is too obtuse (too thick) will result in a robust but duller edge that offers more resistance during cutting, defeating the purpose of a precision Japanese blade. The optimal angle strikes a balance, providing maximum sharpness with sufficient material behind the edge to resist damage during typical use. It’s a careful calibration between fragility and strength, ensuring the blade endures through countless culinary endeavors.

Secondly, the **sharpening angle for Japanese knives** dramatically impacts cutting performance. Different angles are suited for different tasks. A very acute angle (e.g., 10-12 degrees per side) is ideal for delicate slicing through soft ingredients like fish or vegetables, where minimal resistance is desired. This allows the knife to glide through food without tearing or bruising. However, this angle would be unsuitable for heavy-duty tasks involving bone or fibrous ingredients. For these, a slightly more obtuse angle (e.g., 15-18 degrees per side or specialized single-bevel angles) provides the necessary robustness to prevent edge damage while still offering excellent cutting power. The angle fine-tunes the knife’s interaction with the material it cuts, dictating efficiency and precision.

Thirdly, the integrity of the **sharpening angle for Japanese knives** directly relates to the knife’s longevity. Consistently maintaining the correct angle prevents excessive material removal during sharpening, preserving the blade’s original profile and extending its useful life. Over time, improper angles can alter the blade’s geometry, leading to a thicker edge, a loss of its characteristic thinness, or even an uneven profile that makes future sharpening more challenging. By adhering to the intended angle, you ensure that the knife retains its designed cutting properties and remains a high-performing tool for many years. It’s an investment in the future usability of your prized culinary assets.

Finally, the correct **sharpening angle for Japanese knives** influences the tactile feedback and overall user experience. A properly sharpened knife feels responsive and predictable in the hand, gliding through ingredients with satisfying ease. This not only makes cooking more enjoyable but also safer, as less force is required, reducing the risk of slips. Conversely, a knife with an incorrect or inconsistent angle can feel grabby, resistant, or unstable, leading to frustration and potential accidents. The angle, therefore, contributes significantly to the symbiotic relationship between the chef and the knife, transforming a utilitarian act into an intuitive and precise culinary dance. It truly elevates the entire cooking experience beyond the mere act of cutting.

Decoding Japanese Knife Design: A Foundation for Sharpening Angle Selection

To truly master the **sharpening angle for Japanese knives**, one must first understand the fundamental design principles that differentiate them from other cutlery. Japanese knife design is deeply rooted in centuries of tradition, purpose-driven functionality, and an unparalleled mastery of steel. These elements collectively dictate the optimal sharpening approach. Without a solid grasp of how Japanese blades are conceived and constructed, selecting and maintaining the correct angle becomes a guessing game rather than an informed process. This section delves into the core design characteristics that form the bedrock of understanding why specific angles are not just recommended but are essential for these magnificent tools.

Japanese knives are not merely tools; they are often considered works of art, each crafted with a specific purpose in mind. This specialization influences every aspect of their design, from the choice of steel to the grind of the blade, all of which directly impact the ideal **sharpening angle for Japanese knives**. For instance, a knife designed for intricate slicing will have a very different profile and edge requirement than one meant for heavy chopping. The philosophy is often “the right tool for the right job,” and this precision in purpose is reflected in the blade’s geometry. Understanding this foundational design is the first step towards achieving truly exceptional results in your sharpening endeavors, ensuring that you enhance, rather than compromise, the knife’s inherent capabilities. It’s about respecting the craftsmanship.

The historical context also plays a significant role in decoding Japanese knife design. Originating from sword-making traditions, Japanese blades inherited a legacy of metallurgical innovation and a relentless pursuit of sharpness. This heritage led to the development of unique steel compositions and forging techniques, such as the differential hardening seen in traditional Japanese swords (katana), which sometimes find subtle echoes in modern kitchen knives. These historical techniques contribute to the steel’s ability to take and hold incredibly fine edges, which in turn necessitates precise control over the **sharpening angle for Japanese knives**. It’s a continuous lineage of excellence, where every design choice is purposeful.

Furthermore, the cultural aspects of Japanese cuisine have shaped knife design. The emphasis on delicate presentation, precise cuts, and the use of fresh, often raw ingredients has driven the need for knives that can achieve unparalleled sharpness without bruising or tearing food. This demand for precision translates directly into thinner blade geometries and, consequently, more acute sharpening angles. The cutting experience is paramount, and the knife’s design is optimized to provide minimal resistance as it passes through ingredients. Thus, the aesthetic and culinary traditions are inextricably linked to the practical engineering of the blade and its ideal **sharpening angle for Japanese knives**.

Finally, the continuous evolution of materials and manufacturing techniques has subtly refined Japanese knife design, even while upholding core principles. Modern Japanese knives might incorporate advanced powdered steels or innovative composite structures, but the underlying commitment to a thin, high-performance edge remains. This ongoing innovation means that while general principles for the **sharpening angle for Japanese knives** apply, there can be subtle variations even within the same knife type depending on the maker and the specific steel used. Therefore, decoding Japanese knife design is an ongoing learning process, requiring an informed and adaptive approach to sharpening to unlock the full potential of each unique blade.

The Hardness and Thinness: Distinguishing Japanese Steel

A cornerstone of understanding the optimal **sharpening angle for Japanese knives** lies in recognizing the distinct characteristics of Japanese steel: its exceptional hardness and the resulting thinness of the blade. Unlike many Western knives, which typically use softer stainless steels (around 54-58 HRC), Japanese knives often feature high-carbon steel, stainless steel, or Damascus steel compositions that boast significantly higher Rockwell hardness ratings, frequently ranging from 60 HRC to even 65+ HRC. This extreme hardness allows for the creation of incredibly fine and acute cutting edges, which directly translates to superior sharpness and edge retention.

The advantage of harder steel is its ability to be ground to a much thinner edge without deforming under pressure. When we talk about the **sharpening angle for Japanese knives**, this inherent hardness means the steel can support a more acute angle (e.g., 10-15 degrees per side) compared to softer steels which might chip or roll at such fine angles. However, this benefit comes with a trade-off: harder steels can be more brittle. If subjected to lateral stress or used for inappropriate tasks (like prying or cutting through bone), an overly acute or improperly maintained edge on a hard Japanese steel knife can chip rather than flex or roll. This brittleness is why selecting the appropriate angle and sharpening technique is so crucial for these blades.

Furthermore, Japanese blades are typically ground much thinner behind the edge compared to their Western counterparts. This “thinness behind the edge” (TBE) is a critical factor influencing the overall cutting performance and the ideal **sharpening angle for Japanese knives**. A thinner blade offers less resistance as it passes through food, resulting in cleaner cuts and less sticking. When sharpening, maintaining this thinness is paramount. If the sharpening angle is too steep or inconsistent, it can effectively thicken the edge, diminishing the knife’s inherent low-friction cutting ability. The goal is to create an edge that is both incredibly sharp and supported by the optimal amount of material to prevent damage during use.

The composition of Japanese steel also plays a role. Many traditional Japanese knives utilize high-carbon steel, such as Aogami (Blue Paper Steel) or Shirogami (White Paper Steel) from Hitachi Metals. These steels are known for their exceptional purity and ability to achieve razor-like sharpness. Modern Japanese knives often incorporate stainless high-carbon steels like VG-10, SG2/R2, or AUS-10, which offer a balance of hardness, sharpness, and improved corrosion resistance. Each of these steels, while different in composition, shares the common trait of supporting very fine edges, reinforcing the importance of a precise **sharpening angle for Japanese knives**. The specific characteristics of the steel inform how aggressively or delicately one can approach the sharpening process.

In summary, the high hardness and inherent thinness of Japanese steel are not just manufacturing quirks; they are fundamental design choices that profoundly impact the optimal **sharpening angle for Japanese knives**. To preserve their legendary sharpness and ensure their durability, sharpeners must respect these qualities by applying acute, precise angles and using appropriate techniques. Understanding this foundational aspect of Japanese metallurgy is the first step toward truly unlocking and maintaining the exceptional cutting performance that these magnificent blades are famous for delivering in the kitchen.

Understanding Single Bevel (Kataba) vs. Double Bevel (Ryoba) Edges

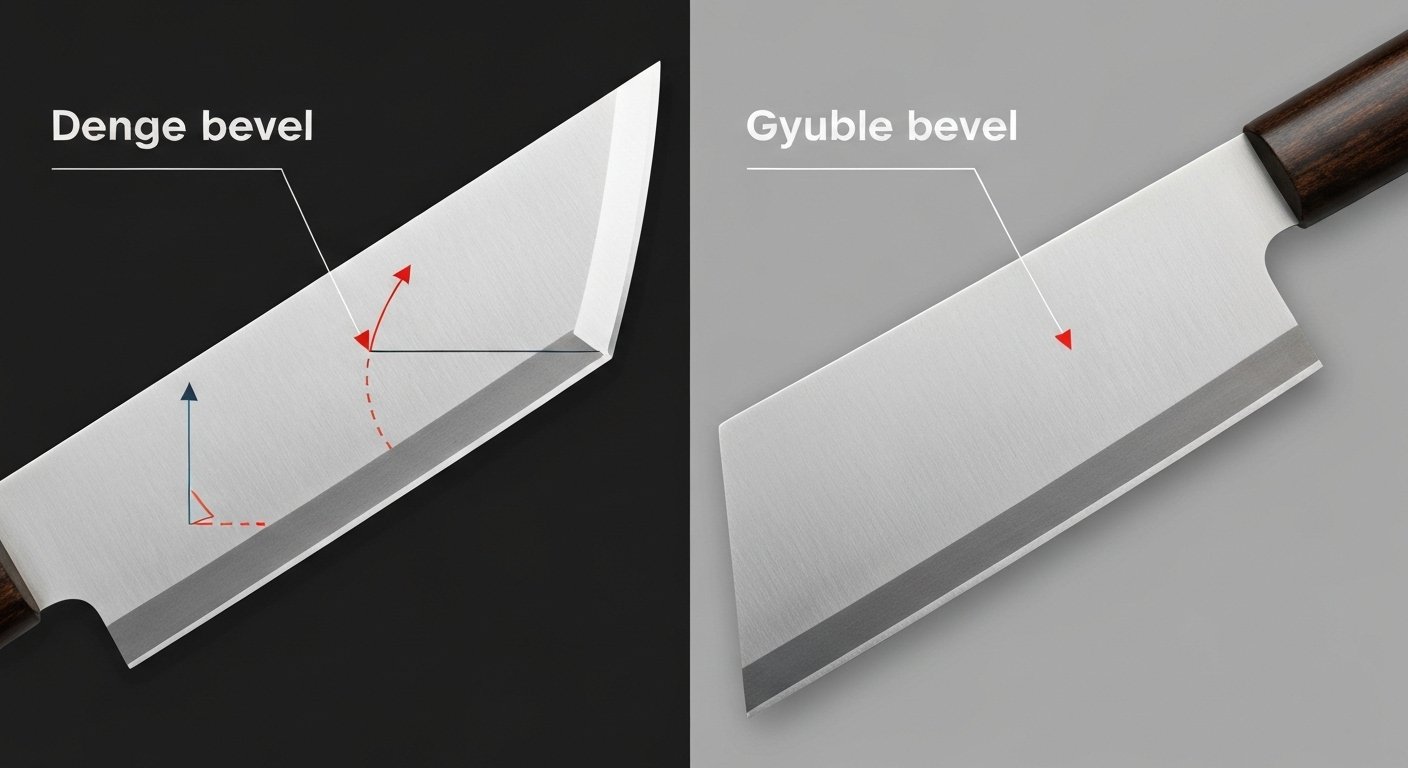

A fundamental distinction in Japanese knife design that profoundly impacts the **sharpening angle for Japanese knives** is the difference between single-bevel (kataba) and double-bevel (ryoba) edges. These two categories represent distinct philosophies of cutting and demand entirely different approaches to sharpening. Mastering this distinction is crucial for anyone looking to properly maintain a Japanese knife collection, as applying the wrong technique can quickly damage the blade or render it ineffective. Each type is meticulously designed for specific culinary tasks, influencing its ideal edge geometry.

Single-Bevel (Kataba) Edges:

Single-bevel knives are the hallmark of traditional Japanese cutlery, exemplified by knives like the Yanagiba (slicing fish), Deba (breaking down fish), and Usuba (thinly slicing vegetables). As the name suggests, these knives are sharpened predominantly on one side, known as the “omote” (front side), while the “ura” (back side) typically features a flat or slightly concave grind with a very subtle edge called the “ura-oshi” or “back bevel.” This asymmetry is what gives them their incredible precision and ability to make exceptionally clean, tear-free cuts, particularly when slicing through fibrous tissues or creating paper-thin slices.

For a single-bevel knife, the primary **sharpening angle for Japanese knives** is applied to the omote side. This angle is generally much steeper than a double-bevel knife, often ranging from 20-35 degrees, to create a robust yet exceedingly sharp edge. The ura side, conversely, is typically only flattened to remove any burr created during sharpening and to provide release from the food being cut. Sharpening the ura side incorrectly can compromise the knife’s unique cutting action and adhesion properties. The goal on the ura is to maintain its flatness and subtly define the micro-bevel that helps with food release and blade stability during the cut. This nuanced approach demands precision and an understanding of the blade’s full profile.

The asymmetric grind causes the knife to naturally steer away from the flat side, which is why single-bevel knives are usually made for right-handed or left-handed users (unless specified as ambidextrous, though these are rare). When sharpening, this steering effect must be considered; consistency on the primary bevel is paramount. Achieving the correct **sharpening angle for Japanese knives** on a single-bevel blade requires practice to feel the full surface of the omote bevel against the stone, ensuring a consistent grind from heel to tip. It’s a skill that rewards patience and a deep respect for the knife’s intended function.

Double-Bevel (Ryoba) Edges:

Double-bevel knives are more common in general-purpose kitchen use, including knives like the Gyuto (chef’s knife) and Santoku (all-purpose kitchen knife). These knives are sharpened on both sides of the blade, creating a symmetrical or slightly asymmetrical V-shaped edge. They are versatile and widely adopted, bridging the gap between traditional Japanese precision and broader utility. While they might not achieve the same extreme thinness of cut as a single-bevel knife, they offer excellent sharpness and are more forgiving for general kitchen tasks and various cutting styles.

The **sharpening angle for Japanese knives** on a double-bevel blade is typically more acute than on Western knives, often falling in the range of 10-15 degrees per side (for a total included angle of 20-30 degrees). This is still much finer than the 20-25 degrees per side (total 40-50 degrees) seen on many European chef’s knives. The key is to sharpen both sides equally, maintaining symmetry and ensuring the edge meets precisely in the center. While some Japanese double-bevel knives might have a slight asymmetry (e.g., 60/40 or 70/30 split in favor of the dominant hand), the principle remains to sharpen both sides, typically alternating strokes.

The process for sharpening double-bevel knives often involves applying the same angle to both sides until a burr forms, then refining and removing the burr from both sides. This symmetrical approach is generally easier for beginners to master than the single-bevel technique. However, precision is still critical to maintain the acute **sharpening angle for Japanese knives** that defines their performance. Consistency in angle from heel to tip, and equal attention to both sides, is what ensures a truly sharp and effective edge for these versatile kitchen workhorses.

Understanding whether your Japanese knife is single-bevel or double-bevel is the foundational knowledge required before even attempting to sharpen it. It dictates the angle, the technique, and the overall philosophy of edge maintenance. For more details on various knife types, visit our Japanese Knife Types section.

How Grind Type Influences the Optimal Sharpening Angle

Beyond the fundamental distinction between single and double bevels, the specific grind type of a Japanese knife plays an equally crucial role in determining its optimal **sharpening angle for Japanese knives**. The “grind” refers to the cross-sectional shape of the blade, from the spine down to the edge. This shape dictates how the blade tapers, influences its cutting performance, and critically, how it should be sharpened to maintain its designed capabilities. Understanding these various grinds is essential for any serious sharpener aiming for peak performance.

1. Flat Grind (Hira Zukuri):

The flat grind is one of the simplest and most common grinds, where the blade tapers in a straight line from the spine to the cutting edge. Many double-bevel Japanese knives, especially chef’s knives (Gyuto) and Santokus, feature a variation of the flat grind. For a flat-ground blade, the **sharpening angle for Japanese knives** is relatively straightforward to apply, as there are no complex curves to contend with. The challenge lies in maintaining a consistent angle across the entire length of the blade and ensuring the edge is thin enough for optimal cutting. The straight taper means that any changes in sharpening angle directly affect the thickness behind the edge, making precise angle control paramount to avoid creating a “shouldered” edge that resists cutting.

2. Convex Grind (Hamaguri or Clamshell):

The convex grind, often referred to as “hamaguri” or “clamshell” grind, is characterized by a slight outward curve from the spine towards the edge. This grind is particularly common on single-bevel knives like Deba and some double-bevel knives designed for durability or specific cutting tasks. The advantage of a convex grind is that it provides greater support behind a very acute edge, making the blade more robust and less prone to chipping, even at very fine angles. When considering the **sharpening angle for Japanese knives** with a convex grind, the challenge is to maintain that subtle curve. Simply sharpening at a fixed angle will flatten the convex profile, compromising its benefits. This often requires a “rolling” motion during freehand sharpening or specialized jigs that can replicate the convex curve. The goal is to blend the newly sharpened bevel seamlessly into the existing convex surface, preserving its strength and cutting efficiency.

3. Hollow Grind (Ura Sukashi):

The hollow grind is predominantly found on the ura (back) side of single-bevel Japanese knives. It features a concave depression that runs along the blade, creating a “hollow” area behind the edge. This hollow grind serves several critical purposes: it reduces friction when cutting, helps release food from the blade, and allows for easier sharpening by concentrating the sharpening surface at the edge and along the “shinogi” line (the ridge where the main bevel meets the hollow). For the **sharpening angle for Japanese knives** with a hollow grind on the ura, the focus is not on sharpening an angle in the traditional sense, but rather on flattening the extremely thin edge and the shinogi line to remove the burr and create suction release. Over-sharpening or flattening the entire ura can ruin the knife’s functionality and food release properties. It requires a delicate touch and a clear understanding of the purpose of the hollow grind.

4. Asymmetrical Grinds (for Double-Bevel):

While most double-bevel knives are symmetrical, some Japanese knives feature asymmetrical grinds, such as a 70/30 or 60/40 ratio, where one side of the blade has a more pronounced bevel than the other. This is often done to optimize cutting for a right- or left-handed user, providing a cleaner cut with less sticking. When determining the **sharpening angle for Japanese knives** with asymmetrical grinds, it’s crucial to respect the intended ratio. This means applying a slightly different angle or spending more time on the more dominant bevel side to maintain the knife’s directional cutting bias. Ignoring this asymmetry can lead to an unbalanced edge that doesn’t perform as intended.

In conclusion, the grind type of a Japanese knife is a fundamental design element that dictates the optimal **sharpening angle for Japanese knives** and the appropriate sharpening technique. Whether it’s the straightforward approach for a flat grind, the nuanced rolling for a convex grind, or the delicate flattening for a hollow grind, understanding these profiles is indispensable for preserving the knife’s inherent cutting characteristics and maximizing its performance in the kitchen.

The Definitive Sharpening Angle Spectrum for Japanese Knives

Navigating the world of Japanese knives requires a precise understanding of their ideal sharpening angles. Unlike the one-size-fits-all approach sometimes applied to Western knives, the **sharpening angle for Japanese knives** is highly specific to the knife type, its intended use, and its unique blade geometry. This definitive spectrum provides a crucial guide for achieving the legendary sharpness and performance that Japanese cutlery is renowned for. Getting these angles right is not just about making the knife sharp; it’s about optimizing its specialized cutting action, ensuring durability, and preserving its inherent design integrity. This section details the typical angle ranges for various popular Japanese knife types, offering a clear roadmap for your sharpening endeavors.

The precision required for the **sharpening angle for Japanese knives** stems from their high-carbon, harder steels and thinner blade profiles. These characteristics allow for much more acute angles than typically seen in European knives, which often range from 20-25 degrees per side (40-50 degrees total included angle). Japanese knives, by contrast, frequently feature angles of 10-15 degrees per side (20-30 degrees total included angle) for double-bevel knives and even steeper primary bevels for single-bevel knives. This finer edge results in less resistance when cutting, leading to cleaner, more effortless slices and greater precision. However, these acute angles also demand greater care and precision during the sharpening process to avoid chipping or rolling the edge. It’s a balance between ultimate sharpness and practical robustness for kitchen use. Understanding this spectrum is the key to unlocking true mastery.

It’s important to remember that these angles are general guidelines. Individual knife makers, specific steel types, and personal preferences can lead to slight variations. Some chefs might prefer a slightly more acute angle for ultimate sharpness on a delicate task, while others might opt for a slightly more obtuse angle for increased durability if their knife sees heavier use. However, deviating too far from these recommended ranges can compromise the knife’s performance and integrity. The goal is always to strike a balance that respects the knife’s original design while meeting the demands of your cutting tasks. This flexibility within the definitive spectrum allows for personal customization while staying within the boundaries of what the knife’s geometry can support, ensuring the longevity and performance of your blades.

Furthermore, understanding the concept of a “total included angle” versus “angle per side” is crucial when discussing the **sharpening angle for Japanese knives**. Most angles are given as “degrees per side,” meaning the angle at which each side of the bevel meets the sharpening stone. For a double-bevel knife, the total included angle is simply the sum of the angles from both sides (e.g., 15 degrees per side equals a 30-degree total included angle). For single-bevel knives, the primary bevel is measured, and the very subtle ura side is generally not measured in the same way, as its function is different. Clarity in terminology helps avoid confusion and ensures you’re applying the correct geometry to your blades, leading to more consistent and effective sharpening results every time.

Ultimately, the definitive **sharpening angle for Japanese knives** is not a rigid rule but a framework built on centuries of metallurgical expertise and practical culinary application. By familiarizing yourself with these specific angle ranges for different knife types, you gain the confidence and knowledge to sharpen your Japanese knives effectively, ensuring they remain exceptional tools that bring joy and precision to your kitchen. This comprehensive understanding transforms sharpening from a chore into a rewarding craft, allowing you to unlock the full potential of your prized Japanese cutlery collection.

Gyuto and Santoku: Navigating the 10-15 Degree Range Per Side

For most home cooks and professional chefs, the Gyuto (Japanese chef’s knife) and Santoku (all-purpose kitchen knife) are the workhorses of the Japanese knife world. These versatile, double-bevel knives are designed for a wide range of tasks, from slicing and dicing vegetables to processing meats. To maintain their characteristic sharpness and cutting efficiency, the optimal **sharpening angle for Japanese knives** like the Gyuto and Santoku typically falls within the range of 10-15 degrees per side, resulting in a total included angle of 20-30 degrees.

Gyuto Knives:

The Gyuto is the Japanese equivalent of a Western chef’s knife, but with a thinner blade profile and often harder steel. Its versatile design makes it suitable for chopping, slicing, dicing, and mincing. For a Gyuto, an initial **sharpening angle for Japanese knives** of around 12-15 degrees per side is a popular starting point. This angle provides an excellent balance of sharpness and durability for daily kitchen tasks. A 12-degree angle per side will yield an incredibly keen edge, ideal for very precise work, while a 15-degree angle per side offers a slightly more robust edge that can withstand a bit more abuse without chipping. The choice often depends on the specific steel of the knife and the user’s cutting habits. For premium Gyuto knives, exploring the lower end of this range (10-12 degrees per side) can truly unlock their maximum slicing potential. Learn more about these versatile knives at Japanese Gyuto Knives.

Santoku Knives:

The Santoku, meaning “three virtues” (meat, fish, and vegetables), is another highly versatile double-bevel knife. It often features a flatter profile than a Gyuto, making it excellent for push-cutting and chopping. Similar to the Gyuto, the ideal **sharpening angle for Japanese knives** like the Santoku is typically between 10-15 degrees per side. Many users find that a 13-15 degree angle per side offers a good combination of sharpness for its multi-purpose role and sufficient strength for everyday tasks. Given its design for all-around use, prioritizing a balance between sharpness and edge stability within this range is key. A slightly more robust angle can be beneficial for a knife that sees diverse daily use, ensuring it stands up to various ingredients. Discover the versatility of Santoku knives at Japanese Santoku Knives.

Considerations for Both:

When setting the **sharpening angle for Japanese knives** within this 10-15 degree range, several factors should be considered:

- Steel Hardness: Harder steels (62+ HRC) can generally support more acute angles (closer to 10-12 degrees per side) with less risk of chipping, while slightly softer steels might benefit from a slightly more obtuse angle (13-15 degrees per side) for durability.

- Intended Use: If your Gyuto or Santoku is primarily used for delicate, precise slicing (e.g., fine julienning), leaning towards the lower end of the angle spectrum will enhance performance. If it’s your only knife and handles everything from vegetables to occasional light butchering, a slightly more robust angle might be preferred.

- User Skill and Cutting Board: Those with refined cutting techniques and who consistently use soft cutting boards (like end-grain wood or composite boards) can often maintain sharper, more acute edges. Less experienced users or those using harder boards might benefit from a slightly more durable angle.

Consistently maintaining the chosen **sharpening angle for Japanese knives** like the Gyuto and Santoku is crucial. Uneven angles or significant deviations can lead to a less efficient edge over time. Regular maintenance with fine grit whetstones and occasional stropping will help preserve this acute angle and keep your knives performing at their peak, ensuring they remain exceptionally sharp and reliable tools for all your culinary needs.

Mastering Asymmetry: Specific Angles for Deba and Yanagiba

While double-bevel knives like the Gyuto and Santoku are versatile, traditional single-bevel Japanese knives such as the Deba and Yanagiba represent the pinnacle of specialized cutting tools, and their unique asymmetry demands a completely different approach to the **sharpening angle for Japanese knives**. Mastering these angles is not just about sharpness, but about preserving their highly specific cutting actions and the delicate balance of their single-sided geometry.

Deba Knives:

The Deba is a robust, heavy single-bevel knife designed primarily for breaking down fish, including cutting through bones (though not large, hard bones). Its thick spine and robust blade provide the necessary power and durability. For a Deba, the primary **sharpening angle for Japanese knives** on the omote (front) side is significantly steeper than on double-bevel knives, typically ranging from 25-35 degrees. This steep angle, combined with the thickness of the blade, provides the strength needed for its heavy-duty tasks, preventing the edge from chipping when encountering bone or tough fish skin. The omote side should be sharpened fully, ensuring the entire bevel makes contact with the stone.

The ura (back) side of the Deba is usually hollow-ground (ura-sukashi) and requires a very specific approach. It is not sharpened at an “angle” in the traditional sense. Instead, the focus is on maintaining the narrow “ura-oshi” or back-bevel and the shinogi line (the ridge where the main bevel meets the hollow). This involves very light polishing strokes on a fine stone, ensuring the ura-oshi remains flat against the stone to remove the burr and create suction release from the food. Over-sharpening the ura side can ruin the knife’s unique food release properties and its precise cutting action. The Deba’s specific geometry makes the **sharpening angle for Japanese knives** on its omote side paramount for robustness, while the ura side is about refinement and functional design. For more on Deba knives, see our category page: Deba Knives.

Yanagiba Knives:

The Yanagiba, with its long, slender single-bevel blade, is the quintessential knife for slicing sashimi and other delicate tasks requiring extreme precision and a smooth, uninterrupted cut. Its design minimizes friction, allowing it to glide through ingredients. The primary **sharpening angle for Japanese knives** like the Yanagiba, applied to the omote side, is generally more acute than a Deba but still steeper than a double-bevel knife, typically ranging from 20-25 degrees. This angle allows for an incredibly keen edge that can slice through raw fish without tearing, preserving its delicate texture and appearance. The length of the blade also means maintaining a consistent angle across its entire sweeping curve is a significant skill challenge.

Like the Deba, the ura side of the Yanagiba is hollow-ground and is not sharpened at an angle. It is treated similarly: with light, flat strokes on a fine stone to remove the burr and refine the ura-oshi. The purpose of the ura on a Yanagiba is to ensure the blade releases cleanly from the food, preventing suction. Any deviation from its intended flatness on the ura side can compromise the slicing action and the knife’s renowned precision. The unique single-bevel geometry of the Yanagiba makes achieving the correct **sharpening angle for Japanese knives** on its omote side essential for its signature clean, pull-free slicing. Explore more about Yanagiba knives: Yanagiba Knives.

General Considerations for Single-Bevel Knives:

- Dominant Hand: Most single-bevel knives are designed for right-handed users. Left-handed versions exist but are less common. The sharpening angles are specific to the dominant hand’s cutting action.

- Full Bevel Contact: When sharpening the omote side, it’s crucial to ensure the entire primary bevel makes consistent contact with the sharpening stone. This often means lifting the spine significantly to achieve the steep angle.

- Delicate Ura Work: The ura side requires extreme delicacy. It’s about refinement and burr removal, not creating a new bevel. Excessive pressure or incorrect angling can quickly damage the hollow grind.

- Consistency: Maintaining consistency along the entire length of the blade, especially for long Yanagibas, is key to an even edge and optimal performance.

Mastering the asymmetric **sharpening angle for Japanese knives** like the Deba and Yanagiba is a significant step in your sharpening journey. It requires patience, a keen eye, and a deep respect for the specialized function and unique geometry of these traditional blades. The rewards are knives that perform with unparalleled precision, embodying centuries of Japanese culinary tradition.

Niche Blades: Petty, Nakiri, and Their Unique Angle Considerations

Beyond the core Gyuto, Santoku, Deba, and Yanagiba, the world of Japanese knives includes a fascinating array of “niche” blades, each designed for specific tasks and possessing unique characteristics that influence their optimal **sharpening angle for Japanese knives**. Understanding these specific considerations ensures that every knife in your collection performs at its peak, maximizing its specialized utility. From nimble Petty knives to precise Nakiris, their unique designs call for tailored sharpening approaches that respect their intended function and geometry.

Petty Knives:

The Petty knife is the Japanese equivalent of a utility or paring knife, typically ranging from 120mm to 180mm in blade length. It’s a versatile, smaller knife ideal for intricate work, peeling, trimming, and small-scale slicing. Most Petty knives are double-bevel, similar to Gyutos and Santokus, but due to their smaller size and often more delicate tasks, their ideal **sharpening angle for Japanese knives** can lean towards the more acute end of the spectrum. An angle of 10-12 degrees per side is often preferred for a Petty knife, allowing for extreme sharpness and precision on fruits, vegetables, and small cuts of meat. The thinness of the blade and its agility make it perfect for detailed work where a super-sharp edge is paramount. While they can be sharpened up to 15 degrees per side, the true joy of a Petty often comes from pushing the boundaries of its sharpness for delicate tasks. For more information, visit our category on Petty Knives.

Nakiri Knives:

The Nakiri is a traditional Japanese vegetable knife, characterized by its straight blade profile and blunt tip. It is designed for push-cutting and chopping vegetables with efficiency and precision, allowing for full contact with the cutting board across the entire blade. Most Nakiri knives are double-bevel, though traditional single-bevel Usuba knives (which serve a similar purpose) also exist. For a double-bevel Nakiri, the optimal **sharpening angle for Japanese knives** typically ranges from 12-15 degrees per side. The straight edge benefits from an angle that provides both excellent sharpness for slicing through tough root vegetables and sufficient durability to withstand repeated chopping motions against a cutting board. Some users might opt for a micro-bevel at a slightly steeper angle (e.g., 18 degrees) to enhance chip resistance if their Nakiri sees very heavy chopping action. The flat profile demands consistent angle application from heel to tip. Check out our detailed guide on Nakiri Knives.

Other Niche Blades and General Considerations:

- Sujihiki (Slicer): A long, slender double-bevel knife for slicing roasts, poultry, and fish. Similar to a Gyuto but longer and thinner. Optimal **sharpening angle for Japanese knives** like the Sujihiki is typically 10-15 degrees per side, leaning towards the more acute end for effortless slicing.

- Honesuki (Boning Knife): A robust, often asymmetrical double-bevel knife for deboning poultry. The angle can vary from 15-20 degrees per side, prioritizing durability given the task of cutting around bones. Some Honesukis might have a slight single-bevel bias (e.g., 70/30) even if double-bevel.

- Kiritsuke (Multi-purpose): Can be single-bevel (traditional) or double-bevel (Western-style). If single-bevel, follow Yanagiba/Usuba angles. If double-bevel (often called “K-tip Gyuto”), treat it like a Gyuto (10-15 degrees per side). The point requires careful angle management.

- Paring Knives: Even smaller than Petty knives, for intricate tasks. Typically 10-12 degrees per side for maximum sharpness.

The key takeaway for all niche Japanese blades is to consider their primary function. A knife designed for delicate slicing will always benefit from a more acute **sharpening angle for Japanese knives**, while one meant for heavier work or tasks involving contact with bones will require a slightly more robust, albeit still sharp, angle. Always prioritize consistency in applying the chosen angle across the entire blade, from heel to tip, to ensure uniform performance. Understanding these specific requirements ensures that each specialized tool in your collection remains a precision instrument, ready for its intended culinary purpose, enhancing efficiency and enjoyment in the kitchen.

Achieving Consistent Sharpening Angle: Techniques and Tool Insights

The theoretical knowledge of the ideal **sharpening angle for Japanese knives** is only half the battle; the other half is the practical ability to consistently achieve and maintain that angle during the sharpening process. Consistency is paramount for both performance and blade longevity. An inconsistent angle can lead to an uneven edge, hot spots, or areas prone to chipping or rolling, ultimately diminishing the knife’s cutting ability. This section explores various techniques and tools designed to help both beginners and experienced sharpeners achieve the precision required for Japanese cutlery, from the tactile art of freehand sharpening to the structured guidance of advanced systems. Each method offers its own benefits and learning curve, catering to different skill levels and preferences in the pursuit of the perfect edge.

The challenge of achieving a consistent **sharpening angle for Japanese knives** stems from the precision of their blade geometry and the often-acute angles they require. A slight deviation of even a few degrees can significantly impact the edge’s performance and durability. This is particularly true for very thin Japanese blades where the margin for error is smaller. Developing the muscle memory for freehand sharpening takes time and practice, while utilizing aids can significantly shorten the learning curve. Regardless of the chosen method, patience and attention to detail are key. It’s a craft that rewards perseverance, transforming a dull blade into a razor-sharp instrument through focused effort and consistent technique. The journey to a truly perfect edge is iterative, refining your approach with each session.

Moreover, the choice of sharpening medium, primarily whetstones for Japanese knives, is intrinsically linked to angle consistency. Whetstones allow for greater control over the angle compared to pull-through sharpeners or electric grinders, which can often remove too much material or apply an incorrect angle that isn’t suitable for delicate Japanese blades. The tactile feedback provided by whetstones also helps in feeling the angle as you sharpen, allowing for immediate adjustments. This sensory connection is vital for developing intuition about the **sharpening angle for Japanese knives**. The texture of the stone, the slurry it creates, and the sound of the blade on its surface all contribute to a richer sharpening experience that enhances precision.

Furthermore, the environment in which you sharpen, including proper lighting and a stable surface, significantly contributes to your ability to maintain a consistent **sharpening angle for Japanese knives**. Good lighting allows you to clearly see the burr formation and the progression of the bevel. A stable surface prevents wobbling or shifting of the stone, which can lead to inconsistencies. Investing in a non-slip whetstone holder or a sturdy workbench can make a surprising difference in the quality of your sharpening. These seemingly small details contribute to creating an optimal sharpening environment, allowing you to focus purely on the angle and pressure, and ultimately improving your results.

Ultimately, achieving a consistent **sharpening angle for Japanese knives** is a journey that combines knowledge, practice, and the right tools. Whether you prefer the meditative art of freehand sharpening or the structured precision of guided systems, the goal remains the same: to restore and maintain the exquisite sharpness that makes Japanese knives so revered. By exploring these techniques and understanding their nuances, you empower yourself to care for your valuable knives properly, ensuring they continue to perform at their very best for many years to come, truly honoring the craftsmanship embedded within each blade.

The Art of Freehand Sharpening: Cultivating Muscle Memory and Feel

For many enthusiasts and professional chefs, freehand sharpening on whetstones represents the pinnacle of knife maintenance. It is an art form that, when mastered, allows for unparalleled control over the **sharpening angle for Japanese knives**, adapting to specific blade geometries and desired edge characteristics. While it demands patience and practice, cultivating muscle memory and developing a keen “feel” for the blade against the stone offers the most versatile and rewarding sharpening experience, allowing for truly customized edge profiles.

The core principle of freehand sharpening lies in consistently maintaining the chosen **sharpening angle for Japanese knives** without the aid of mechanical guides. This involves finding the correct angle by feel, often by lifting the knife’s spine until the edge bevel sits flush against the stone, and then locking your wrist and arm into that position. Many experienced sharpeners advocate finding the angle by resting the knife lightly on the stone and slowly lifting the spine until the smallest amount of water or slurry gathers precisely along the entire cutting edge, indicating proper contact. This visual and tactile feedback is crucial for establishing the initial angle.

Developing muscle memory is key to consistency. This comes from repetition: hundreds, even thousands, of strokes. As you practice, your hands and arms learn the precise angle, pressure, and motion required. Initially, you might find yourself constantly checking the angle, but over time, your body learns to instinctively reproduce it. This allows for fluid, continuous strokes that lead to a more uniform and refined edge. The goal is to make the application of the **sharpening angle for Japanese knives** feel natural and effortless, almost an extension of your body’s movements, transforming a mechanical task into a meditative art.

The “feel” aspect is equally important. This refers to the subtle sensory cues that tell you how the sharpening is progressing. You’ll learn to feel the drag of the blade on the stone, the change in resistance as metal is removed, and the distinct sensation of a burr forming along the edge. For instance, as you remove material and approach the apex, the knife might feel “stickier” or “grab” the stone more. When a burr forms, running your finger carefully along the edge will reveal a slight lip. These tactile sensations are invaluable indicators that you are maintaining the correct **sharpening angle for Japanese knives** and achieving the desired outcome. With practice, you can even hear the subtle changes in sound as the edge refines.

For single-bevel knives, freehand sharpening is almost a necessity to properly address the complex omote and ura sides. The ability to subtly “roll” the knife on a convex grind or meticulously flatten the ura side to remove the burr requires a level of dexterity that mechanical guides often cannot replicate. This is where the art truly shines, as you become intimately familiar with the unique geometry of each blade, intuitively adjusting your technique to honor its design and optimize its specific **sharpening angle for Japanese knives**. This deep connection between sharpener and knife is one of the most rewarding aspects of freehand sharpening, turning a chore into a fulfilling craft.

While the learning curve can be steep, the rewards of freehand sharpening are immense. It grants you the ultimate control over your knife’s edge, allowing you to customize its performance for any task and ensuring it remains a true extension of your culinary skill. For a comprehensive guide on this method, explore our Whetstone Sharpening guide.

Precision with Assistance: The Efficacy of Angle Guides and Jigs

For those new to sharpening or seeking greater consistency without the extensive practice required for freehand mastery, angle guides and sharpening jigs offer an invaluable solution. These tools provide a mechanical means to maintain a precise **sharpening angle for Japanese knives**, significantly reducing the learning curve and ensuring repeatable results. They bridge the gap between complete novice and proficient sharpener, making the process more accessible and less intimidating while still delivering excellent edge quality.

Angle Guides:

The simplest form of assistance comes in the shape of small, clip-on angle guides. These typically attach to the spine of the knife, providing a pre-set angle that rests against the whetstone. Common angles available for these guides include 15 and 20 degrees, which are suitable for many double-bevel Japanese knives (when considering total included angle). For instance, a 15-degree guide might be used to maintain a 15-degree angle per side, or a 7.5-degree angle per side if used on a specific type of guide. Users simply slide the knife along the stone, ensuring the guide maintains constant contact. While helpful, these basic guides have limitations: they may not offer the precise acute angles (e.g., 10-12 degrees per side) desired for many Japanese knives, and they might not accommodate the varied blade geometries or lengths perfectly. However, they are an excellent starting point for learning the feel of consistent pressure and motion. A popular example is the Wüsthof sharpening angle guide, widely available, which assists in finding consistent angles, though it is more commonly associated with Western knives, the principle applies. Visit the Wüsthof official website for examples of their accessories.

Sharpening Jigs:

More sophisticated jigs offer greater precision and adaptability. These systems typically clamp the knife securely, allowing the user to set a precise **sharpening angle for Japanese knives** using aprotractor or a pre-calibrated mechanism. The knife then slides along a rail or pivot system, ensuring that the angle remains absolutely consistent throughout the stroke. Examples include the Spyderco Sharpmaker, Lansky Sharpening System, and various types of rod-guided systems. These jigs often come with different abrasive stones or rods, allowing for a full progression from coarse to fine grits. They are particularly effective for maintaining very acute and consistent angles on double-bevel knives, minimizing the risk of uneven sharpening. The initial setup might take a bit of time, but once set, the consistency is unmatched, making them invaluable for those who value precision above all else.

Benefits of Angle Guides and Jigs:

- Consistency: The primary benefit is the ability to consistently apply the precise **sharpening angle for Japanese knives** across the entire length of the blade, from heel to tip. This eliminates guesswork and reduces the likelihood of rounded or inconsistent edges.

- Reduced Learning Curve: Beginners can achieve excellent results much faster than with freehand sharpening, building confidence and understanding the principles of edge creation without the frustration of inconsistent angles.

- Reproducibility: Once you find an angle that works perfectly for a particular knife, jigs allow you to easily reproduce that exact angle during future sharpening sessions, ensuring long-term edge integrity.

- Safety: By securing the knife or providing a stable guide, these tools can make the sharpening process safer, reducing the risk of accidental cuts.

Limitations to Consider:

- Single-Bevel Challenge: Many jigs are primarily designed for symmetrical double-bevel edges and may struggle to properly address the complex, asymmetrical geometry of traditional single-bevel Japanese knives like Yanagiba or Deba, especially their ura side.

- Fixed Angles: Some simpler guides offer only fixed angles, which might not be perfectly suited for all Japanese knife types or desired performance levels.

- Less Feel: While precise, jigs can sometimes reduce the tactile “feel” that freehand sharpeners develop, which is crucial for understanding burr formation and edge refinement.

Despite these limitations, angle guides and jigs are excellent tools for achieving precision when working on the **sharpening angle for Japanese knives**, particularly for double-bevel blades. They democratize the sharpening process, allowing more people to experience the joy of a truly sharp knife. For a broader look at sharpening accessories, visit our Knife Sharpening Tools section.

Advanced Systems: Exploring Controlled Angle Sharpeners for Japanese Blades

For enthusiasts seeking the utmost precision, repeatability, and control over the **sharpening angle for Japanese knives**, advanced controlled-angle sharpening systems represent the zenith of sharpening technology. These sophisticated devices provide unparalleled accuracy, allowing users to dial in exact angles and maintain them consistently across a wide range of blades. While they represent a significant investment in both cost and learning time compared to basic guides, their capability to create perfectly symmetrical and exceptionally keen edges is unmatched, making them a favorite among collectors and professionals.

These systems typically involve a rigid frame, a secure clamping mechanism for the knife, and an articulated arm that holds the abrasive stone at a precisely set angle. The user then moves the stone along the edge of the clamped knife, ensuring that the exact **sharpening angle for Japanese knives** is applied consistently from heel to tip. The level of control offered by these systems allows for micro-adjustments in angle, enabling the user to experiment with extremely acute edges or custom micro-bevels with scientific precision. They eliminate the variables of human inconsistency, delivering highly reproducible results every time.

Key Players in Advanced Systems:

- Wicked Edge: Known for its dual-sided sharpening capabilities, allowing simultaneous sharpening of both sides of a double-bevel knife. The Wicked Edge system offers extremely precise angle control (often down to 0.05-degree increments) and a wide range of abrasive stones, including diamond, ceramic, and strops. This precision makes it excellent for achieving extremely fine and consistent **sharpening angle for Japanese knives** like Gyutos and Santokus, and for creating mirror-polished edges. Visit Wicked Edge’s official website for more details.

- KME Sharpeners: Similar to Wicked Edge in principle, KME systems also clamp the knife and guide the stone on a rod. They are highly regarded for their robust construction, portability, and versatility with various stone types. KME systems offer excellent precision for setting the **sharpening angle for Japanese knives**, making them popular for those who want consistent, professional-level edges without needing advanced freehand skills. Their modularity allows for a wide range of customization. You can find more information at KME Sharpeners’ official website.

- Edge Pro Apex/Professional: The Edge Pro system uses a different mechanism where the knife rests on a platform, and the abrasive stone is moved along a guide rod. This system is praised for its ability to sharpen long blades with ease and for its flexibility in angle setting. It’s highly effective for putting an exceptionally keen and consistent **sharpening angle for Japanese knives**, especially for double-bevel types. The learning curve is moderate, but the results are exceptional, allowing for precise bevel control. Explore their products at Edge Pro’s official website.

Advantages of Advanced Systems for Japanese Knives:

- Unparalleled Precision: These systems can set and hold an exact **sharpening angle for Japanese knives**, ensuring perfectly symmetrical bevels and consistent sharpness along the entire edge.

- Reproducibility: Once an ideal angle is found for a specific knife, it can be recorded and precisely replicated for future sharpening sessions, maintaining the blade’s original geometry.

- Fine Edge Capability: They excel at creating very acute angles and highly polished edges, which are characteristic of premium Japanese knives.

- Reduced Skill Requirement: While operating them requires some learning, they drastically reduce the freehand skill needed to achieve professional-level results.

Considerations for Japanese Blades:

- Single-Bevel Limitation: Most advanced systems are optimized for double-bevel knives. While some can adapt to single-bevels (e.g., by sharpening one side at a time and then freehanding the ura), they don’t fully replicate the complex nuances of traditional single-bevel sharpening.

- Initial Cost and Setup: These systems are a significant investment and require time to learn their proper setup and operation for each knife.

- Blade Clamping: Thinner Japanese blades require careful clamping to avoid damage, and some systems might need custom jaws or shims for optimal securement.

For those dedicated to achieving the absolute best edge on their Japanese knives and who appreciate scientific precision, advanced controlled-angle sharpeners are an exceptional choice. They transform sharpening into a highly controlled, almost laboratory-like process, ensuring that the **sharpening angle for Japanese knives** is always perfect, delivering maximum performance and longevity for your valuable cutlery.

Beyond the Primary Bevel: Micro-bevels, Polishing, and Edge Longevity

Achieving a razor-sharp primary edge by setting the correct **sharpening angle for Japanese knives** is a significant accomplishment, but the journey to a truly optimized and durable edge extends beyond this initial step. For Japanese knives, where ultimate sharpness meets refined cutting performance, secondary processes like applying micro-bevels, meticulous polishing, and consistent stropping play crucial roles. These advanced techniques refine the edge, enhance its durability, and significantly contribute to the overall longevity and performance of the blade. Understanding these nuances moves you from simply “sharp” to truly “perfected,” ensuring your knives maintain their peak form for extended periods.

The concept of “edge longevity” for Japanese knives isn’t just about how long the knife stays sharp; it’s about how well it performs over time, resisting damage and maintaining its intricate geometry. While the initial **sharpening angle for Japanese knives** sets the foundation, subsequent treatments like micro-bevels or extensive polishing directly contribute to the edge’s resilience against the stresses of cutting. A beautifully polished edge, for example, offers less friction and is less prone to micro-chipping than a coarser edge, even if both are equally sharp immediately after sharpening. These seemingly subtle refinements compound to create a superior cutting experience and significantly extend the time between major sharpening sessions.

Furthermore, the practice of refining the edge beyond the primary bevel is deeply rooted in traditional Japanese blade crafting. Historically, swordsmiths and knife makers dedicated significant effort to the final stages of polishing and honing to enhance both the aesthetic and functional properties of the blade. This attention to detail has carried over into modern Japanese kitchen knives, where the pursuit of the ultimate edge often involves multiple steps on increasingly finer abrasive materials. It’s a testament to the belief that true excellence lies in the details, ensuring that every facet of the **sharpening angle for Japanese knives** and the surrounding steel is optimized for peak performance.

The interplay between the primary **sharpening angle for Japanese knives** and these advanced finishing techniques is dynamic. A well-set primary angle provides the structural integrity, while the micro-bevels and polishing add layers of durability and finesse. For instance, a very acute primary angle might be deliberately chosen for maximum sharpness, with the understanding that a slightly more obtuse micro-bevel will be applied to prevent chipping. This strategic layering of angles and finishes is what allows Japanese knives to achieve their legendary sharpness while remaining practical tools for the rigors of a professional kitchen. It’s a sophisticated approach that optimizes for both performance and resilience, a true hallmark of Japanese craftsmanship.

Ultimately, venturing beyond the primary bevel in your sharpening process transforms your knife maintenance from a basic skill into a refined craft. By incorporating micro-bevels, dedicated polishing, and regular stropping, you not only elevate the immediate sharpness of your Japanese knives but also significantly extend their cutting life and enhance their overall performance. This holistic approach to edge care ensures that your valuable tools remain a source of pride and precision in your culinary endeavors, embodying the enduring legacy of the perfect **sharpening angle for Japanese knives** and its continuous refinement.

The Role and Application of Micro-bevels in Edge Durability

While the primary **sharpening angle for Japanese knives** dictates the main cutting edge, the judicious application of a micro-bevel can significantly enhance edge durability without sacrificing much in terms of sharpness. A micro-bevel, also known as a secondary bevel or a “relief” bevel, is a very small, slightly steeper angle applied to the very apex of the primary cutting edge. It’s typically created with a very fine grit stone or a strop, effectively strengthening the weakest point of the knife’s edge and making it more resistant to chipping or rolling.

Why Use a Micro-bevel?

Japanese knives, with their often very acute primary **sharpening angle for Japanese knives** (e.g., 10-12 degrees per side), can be prone to chipping if subjected to lateral stress, contact with hard surfaces, or heavy cutting tasks. This is particularly true for knives made from very hard, brittle steels. A micro-bevel addresses this vulnerability by adding a small amount of material to the very apex, slightly increasing the included angle at the cutting point. For example, if your primary bevel is 12 degrees per side, you might apply a micro-bevel at 15 degrees per side. This slight increase in angle provides a stronger “shoulder” to support the fine tip of the edge, making it more resilient against impact and wear.

Application of a Micro-bevel:

The application of a micro-bevel is generally the last sharpening step, performed after the primary bevel has been fully sharpened and deburred. It’s done with a very light touch, often on a fine ceramic stone (around 3000-8000 grit) or even a ceramic rod. The process involves raising the spine of the knife just a few degrees higher than the primary sharpening angle and applying a very small number of light strokes (e.g., 2-5 strokes per side). The goal is to create a barely visible, hair-thin secondary bevel right at the very edge. For single-bevel knives, a micro-bevel might be applied only to the omote (front) side at a slightly steeper angle, further reinforcing the cutting edge while maintaining the primary bevel’s optimal slicing performance. This precise and deliberate action ensures the **sharpening angle for Japanese knives** is perfectly augmented for durability.

Benefits for Japanese Knives:

- Increased Durability: The most significant benefit is enhanced resistance to chipping and rolling, especially for very thin or highly acute edges. This is crucial for knives seeing heavy use or when encountering tougher ingredients.

- Edge Retention: A micro-bevel can sometimes improve perceived edge retention, as the strengthened edge is less likely to deform quickly.

- Easier Maintenance: For routine touch-ups, it’s often easier and faster to refresh just the micro-bevel with a few quick strokes on a fine stone or ceramic rod, preserving the primary **sharpening angle for Japanese knives** for longer periods.

- Versatility: It allows users to enjoy the benefits of a very acute primary grind for minimal cutting resistance, while still providing enough robustness for everyday tasks.

Considerations:

- Subtle Impact on Sharpness: While a micro-bevel does slightly increase the total included angle at the very apex, if applied correctly (very small and subtle), the impact on initial sharpness is minimal and often imperceptible in practical use.

- Skill Required: Applying a consistent micro-bevel requires a delicate touch and a good understanding of angles. Over-doing it can result in a blunt or ineffective edge.

In essence, the micro-bevel is a sophisticated refinement that augments the chosen **sharpening angle for Japanese knives**, providing an extra layer of protection and prolonging the life of a keen edge. It’s a technique that allows knife owners to push the boundaries of sharpness while ensuring their valuable tools remain resilient and high-performing for years to come.

The Science of Stropping: Refining the Sharpening Angle for Peak Performance

After a knife has been sharpened on progressively finer whetstones and the correct **sharpening angle for Japanese knives** has been established, the process isn’t truly complete until the edge has been stropped. Stropping is a crucial, often overlooked, final step that refines the edge to peak performance, removing the microscopic burr that remains after even the finest stone, and subtly polishing the very apex of the blade. It’s the science of bringing an edge from merely “sharp” to “razor-sharp” and beyond, achieving a level of refinement that enhances cutting feel and longevity.

What is Stropping?

Stropping involves drawing the knife’s edge along a soft, abrasive surface, typically a leather strop (often mounted on wood), balsa wood, or even dense cardboard, often coated with an abrasive compound (like chromium oxide, diamond paste, or cerium oxide). Unlike sharpening, which removes significant amounts of steel to create a new bevel, stropping removes only the most minute particles, straightens the very tip of the edge, and polishes the apex. The action is always “trailing edge” – the spine leads, not the edge – to avoid cutting into the strop and rounding the edge. The **sharpening angle for Japanese knives** should be maintained precisely during stropping, mirroring the final sharpening angle.

The Science Behind Stropping:

- Burr Removal: Even after honing on a very fine grit stone (e.g., 6000-12000 grit), a microscopic burr (a thin, wire-like curl of metal) often remains along the cutting edge. This burr, invisible to the naked eye, can reduce cutting efficiency and eventually fold over or break off, leading to premature dullness. Stropping gently removes this burr, leaving a clean, true edge.

- Edge Alignment: The very apex of a sharpened edge can still be slightly misaligned. Stropping helps to realign these microscopic irregularities, ensuring the edge is perfectly straight and consistent along its entire length. This leads to a smoother, more efficient cut.

- Micro-Polishing: Abrasive compounds on the strop subtly polish the apex of the edge. This micro-polishing reduces friction, making the knife glide through food more easily. A smoother, more polished edge is also less prone to micro-chipping, as there are fewer irregularities for stress to concentrate upon, thus enhancing the durability derived from the initial **sharpening angle for Japanese knives**.

- Deburring: For single-bevel knives, especially on the ura (back) side, stropping with a very light touch can be an effective way to remove the burr without applying a traditional sharpening angle. This maintains the hollow grind’s integrity while achieving a crisp edge.

Benefits for Japanese Knives:

- Unmatched Sharpness: Stropping is the final step in achieving truly hair-popping, effortlessly slicing sharpness, characteristic of high-performance Japanese blades.

- Improved Edge Retention: By removing the burr and strengthening the edge, stropping helps the knife hold its keen edge longer.

- Enhanced Cutting Performance: A polished edge experiences less drag, making cutting feel smoother and more precise.

- Routine Maintenance: Regular light stropping can extend the time between full sharpening sessions on whetstones, helping to maintain the **sharpening angle for Japanese knives** for longer periods.

Incorporating stropping into your sharpening routine is a game-changer for Japanese knives. It transforms a functional edge into a truly refined instrument, unlocking the full potential of its **sharpening angle for Japanese knives** and delivering an unparalleled cutting experience. It’s a small step that yields significant results in both performance and edge longevity. For overall care, remember to check our Knife Maintenance guides.

Preserving the Edge: Long-Term Maintenance and Angle Integrity

Achieving the perfect **sharpening angle for Japanese knives** is an investment in time and skill, but its value is realized over the long term through diligent edge preservation. A knife’s edge is constantly under stress during use, and without proper care, even a perfectly sharpened blade will quickly degrade. Long-term maintenance isn’t just about occasional sharpening; it’s a holistic approach that encompasses daily habits, storage, and routine touch-ups to ensure the integrity of the meticulously set sharpening angle and prolong the life of your valuable Japanese cutlery. It’s about more than just sharpness; it’s about maintaining the knife’s designed performance and structural integrity over years of use.

1. Use Proper Cutting Surfaces:

The single most impactful factor in preserving the **sharpening angle for Japanese knives** is the cutting surface. Always use soft cutting boards made of end-grain wood, bamboo, or high-quality composite materials. Avoid hard surfaces like glass, ceramic, stone, or even hard plastic, as these will rapidly dull, chip, or roll your knife’s edge. Each cut into a hard surface abrades the precisely sharpened angle, leading to micro-damage that accumulates quickly. A softer board absorbs impact, cushioning the edge and allowing it to retain its sharpness much longer. This fundamental choice is paramount for preventing immediate degradation of your knife’s edge geometry.

2. Proper Cutting Technique:

Employing correct cutting techniques is vital. Avoid twisting, rocking, or prying motions, especially with delicate Japanese blades. Use a smooth, consistent slicing or push-cutting motion that minimizes lateral stress on the edge. Never “chop” with a knife not designed for it, and be mindful of bones or very hard ingredients. For single-bevel knives, understand their specific steering properties and cut accordingly. A good technique reduces unnecessary stress on the **sharpening angle for Japanese knives**, preventing premature damage and maintaining the edge’s integrity. It’s about letting the knife do the work, rather than forcing it.

3. Immediate Cleaning and Drying:

After each use, immediately hand wash your Japanese knife with mild soap and water, and thoroughly dry it. Do not put Japanese knives in a dishwasher. Dishwashers expose knives to harsh detergents, extreme temperatures, and vigorous washing cycles that can cause corrosion (especially on high-carbon steels), dull the edge through jostling, and damage wooden handles. Drying immediately prevents rust and staining, particularly crucial for non-stainless or semi-stainless steels, ensuring the surface that supports the **sharpening angle for Japanese knives** remains pristine.

4. Safe Storage:

How you store your knives directly impacts their edge integrity. Never store Japanese knives loose in a drawer where they can bump against other utensils, as this is a common cause of edge damage, chipping, or dulling the precise **sharpening angle for Japanese knives**. Ideal storage solutions include:

- Magnetic Knife Strips: Ensure the knife is placed spine-first and gently rolled onto the magnet to avoid scratching or damaging the edge.

- Knife Blocks: Store knives in clean, dry slots.

- Sayas (Wooden Sheaths): Traditional and excellent for protecting individual blades.

- Knife Rolls/Cases: Ideal for transport or larger collections.

5. Routine Touch-ups and Stropping: