Embarking on a culinary journey often begins with the right tools, and for many, that means exploring the world of sharp Japanese knives. These exquisite blades are celebrated globally for their unparalleled cutting performance and masterful craftsmanship. Achieving true precision in the kitchen depends heavily on a knife that holds an exceptional edge, making Japanese cutlery a top choice for both professional chefs and home cooking enthusiasts alike.

This ultimate guide delves deep into the science, art, and maintenance of these remarkable tools. We’ll uncover what makes them so extraordinarily sharp and how you can harness their potential for culinary excellence. Prepare to elevate your cooking experience with blades designed for unmatched efficiency and effortless control. 🔥

📋 Table of Contents

- 📌 Unveiling the World of Truly Sharp Japanese Knives

- 📌 The Science Behind Razor-Sharp Japanese Knives: Steel, Geometry, and Craftsmanship

- 📌 Top Japanese Knives Renowned for Unmatched Sharpness

- 📌 Achieving and Maintaining Peak Sharpness: A Master’s Guide

- 📌 Advanced Steel Metallurgy for Superior Edge Retention

- 📌 Beyond the Edge: Unlocking the Molecular Secrets of Japanese Knife Sharpness

- 📌 Frequently Asked Questions About Sharp Japanese Knives

- 📌 Essential Tools & Resources for Maintaining Sharp Japanese Knives

- 📌 Real-World Impact: The Advantage of Sharp Japanese Knives in Professional Kitchens

- 📌 Embracing the Edge: Your Journey to Unparalleled Sharpness with Japanese Knives

Unveiling the World of Truly Sharp Japanese Knives

The pursuit of culinary perfection often leads to the legendary performance of sharp Japanese knives. These tools are not merely instruments; they are a testament to centuries of metalworking artistry and dedication. Understanding their essence is the first step towards appreciating their power.

Many home cooks and professional chefs wonder about the inherent superiority of these blades. Their reputation for unparalleled sharpness is well-earned, rooted deeply in unique manufacturing philosophies and meticulous attention to detail. This section explores the fundamental characteristics that set them apart.

What Makes Japanese Knives Exceptionally Sharp?

The exceptional sharpness of Japanese knives stems from a combination of factors: superior steel, advanced heat treatment, and precise blade geometry. Unlike many Western counterparts, Japanese blades often feature harder steel, allowing for a much finer, more acute edge angle. This results in a blade that can slice through ingredients with minimal resistance.

Traditional craftsmanship, passed down through generations, plays a crucial role. Artisans spend countless hours perfecting the grinding and polishing processes. This meticulous approach ensures that each knife achieves an incredibly keen and durable edge, ready for the most demanding kitchen tasks. ✅

Why Optimal Sharpness is Crucial for Culinary Excellence

Optimal sharpness is not just about ease of cutting; it significantly impacts the quality of your food and your overall cooking experience. A truly sharp knife reduces cellular damage in ingredients, preserving their texture, flavor, and nutritional value. Think of the difference between a clean slice of tomato and a squashed one.

Beyond ingredient integrity, a razor-sharp blade dramatically enhances safety and efficiency. Less force is required, minimizing the risk of slips and accidents. Professional kitchens, for example, rely on peak sharpness to maintain speed and precision during high-volume prep. For a comprehensive overview of Japanese cutlery, consider reading our Ultimate Master’s Guide to Japanese Knives.

The Science Behind Razor-Sharp Japanese Knives: Steel, Geometry, and Craftsmanship

The legendary cutting ability of sharp Japanese knives is no accident; it is the culmination of scientific understanding applied through centuries of artisanal skill. Every aspect, from the selection of raw materials to the final edge, contributes to their remarkable performance. This section explores these critical elements.

The interplay between different types of steel, the precise angles of the blade, and the ancient forging techniques creates a synergy unmatched by many other knife traditions. Understanding these foundations provides a deeper appreciation for the tools themselves. It also empowers you to make informed choices when investing in premium cutlery. 💡

High-Carbon vs. Stainless: Understanding Core Steel Properties

Japanese knives primarily utilize two categories of steel: high-carbon and stainless. High-carbon steels, like Aogami (Blue) and Shirogami (White), offer exceptional hardness, allowing for an incredibly acute and long-lasting edge. They are prized for their ability to achieve a “live” sharpness, but require diligent care to prevent rust.

Stainless steels, such as VG-10 and SG2 (R2), provide superior corrosion resistance and ease of maintenance, making them popular for many users. While generally slightly softer than their carbon counterparts, modern stainless alloys can still achieve impressive sharpness and edge retention. For a deep dive into this topic, explore Mastering Carbon Steel Japanese Knives.

Blade Geometry and Edge Angles: The Foundation of Precision

The geometry of a Japanese knife blade is arguably its most defining characteristic when it comes to sharpness. Many feature a single-bevel (kataba) or a highly asymmetrical double-bevel (ryoba) design. This allows for an extremely thin blade behind the edge, facilitating precise, effortless cuts.

Edge angles are often much steeper than Western knives, sometimes as acute as 10-15 degrees per side, compared to 20-25 degrees. This finer angle translates directly into superior cutting performance. The delicate balance of blade thickness, grind, and edge angle creates the legendary precision associated with these knives. 🎯

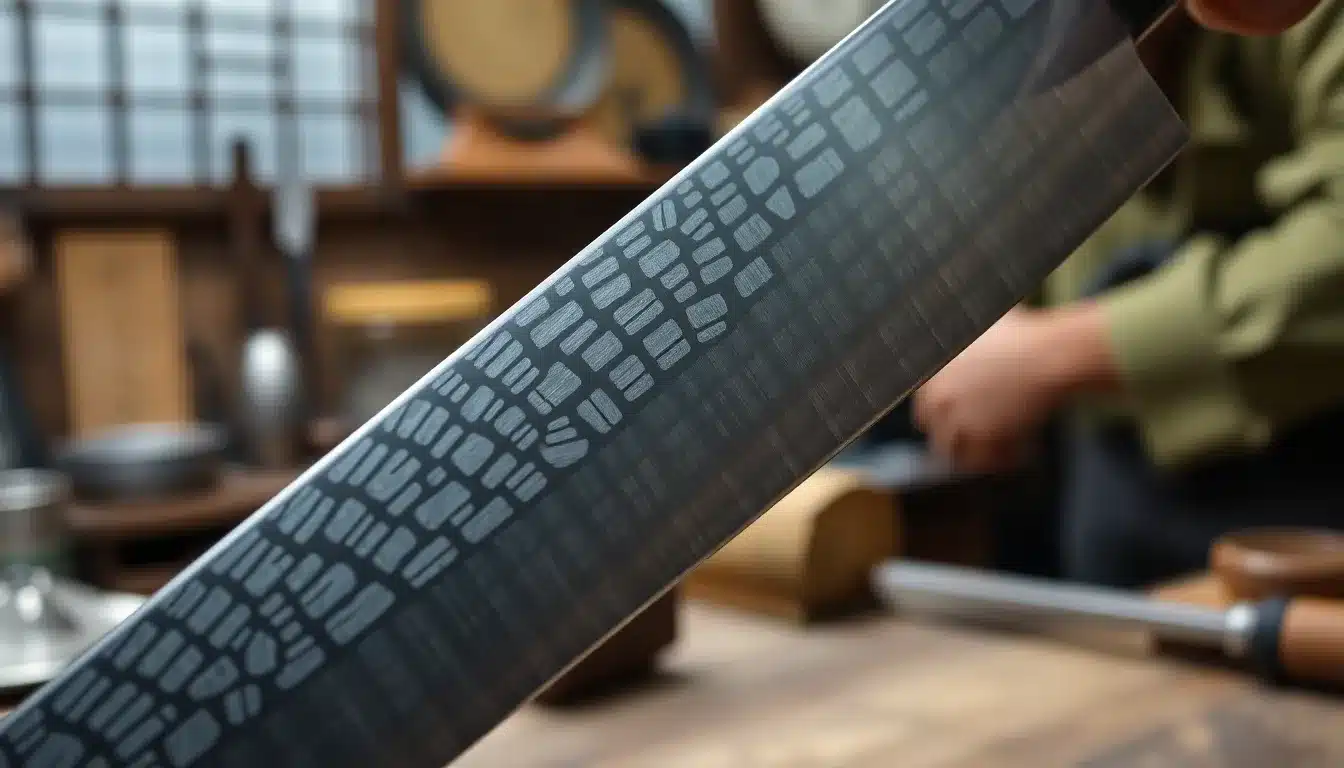

Traditional Forging Techniques: Honyaki, Kasumi, and San-Mai Construction

Traditional Japanese forging methods are integral to creating sharp Japanese knives. Honyaki, the purest and most challenging technique, involves forging a single piece of high-carbon steel, often differentially hardened like a samurai sword. This results in an incredibly hard edge and a tougher spine.

Kasumi construction involves forging a layer of hard carbon steel (the core) with softer iron (the cladding) to provide toughness and protection. San-Mai (three-layer) is similar, using a hard core steel clad with softer stainless steel, offering a balance of performance and maintenance. These techniques are centuries old, passed down through artisan families, resulting in superior tools.

Top Japanese Knives Renowned for Unmatched Sharpness

When seeking truly sharp Japanese knives, specific blade types and brands consistently rise to the top. Each knife is designed with a particular purpose, yet all share the common thread of exceptional sharpness. Understanding these categories helps in selecting the perfect tool for your culinary ambitions.

From versatile workhorses to highly specialized instruments, the range of Japanese cutlery offers a solution for every cutting task. This section highlights the most popular and critically acclaimed knives and the manufacturers behind their legendary sharpness. Discovering the right knife is a journey of precision.

Gyuto and Santoku: Versatile Blades for Everyday Precision

The Gyuto is often referred to as the Japanese chef’s knife, celebrated for its versatility and incredible sharpness. With its pointed tip and curved belly, it excels at rocking cuts, slicing, dicing, and mincing a wide array of ingredients. It’s an indispensable tool for nearly any kitchen task, offering unmatched precision.

The Santoku, meaning “three virtues” (meat, fish, vegetables), is another popular all-purpose knife. Its flatter profile and rounded or sheep’s foot tip make it ideal for push-cutting and chopping. Both Gyuto and Santoku are excellent entry points into the world of sharp Japanese knives, delivering superb performance for daily use. Explore the precision of the Gyuto with our guide to Japanese Gyuto Knives: Unmatched Precision.

Specialized Sharpness: Yanagiba, Deba, and Nakiri for Specific Tasks

For more specialized tasks, Japanese cutlery offers tailored solutions. The Yanagiba, with its long, slender, single-bevel blade, is the quintessential knife for preparing sashimi and sushi, creating exceptionally clean, smooth slices of fish. Its acute edge ensures minimal tearing of delicate proteins.

The Deba is a robust, thick-spined knife designed for butchering fish, from filleting to deboning. Its weight and extreme sharpness make short work of tough tasks. The Nakiri, characterized by its straight blade and blunt tip, is perfect for precision vegetable prep, allowing for efficient chopping and finely julienned cuts. Each knife embodies specialized sharpness for peak performance.

Leading Brands for Sharp Japanese Knives: Shun, Miyabi, Tojiro, and Global

Several brands stand out for their commitment to producing exceptionally sharp Japanese knives. Shun, known for its beautiful Damascus cladding and razor-sharp edges, combines traditional Japanese craftsmanship with modern technology. According to Shun’s official site, their blades undergo a rigorous finishing process to achieve their signature sharpness.

Miyabi, a brand under Zwilling J.A. Henckels, also merges German engineering with Japanese artisan techniques, resulting in stunning and incredibly sharp blades. Tojiro offers excellent value, providing professional-grade sharpness at accessible price points. Global knives, famous for their distinctive all-stainless-steel design, are favored by many chefs for their balanced feel and enduring sharpness. These brands are benchmarks in the industry.

Achieving and Maintaining Peak Sharpness: A Master’s Guide

Owning sharp Japanese knives is only half the equation; mastering their maintenance is crucial for sustaining their legendary performance. Without proper care, even the finest blade will dull over time. This section provides essential guidance on how to achieve and maintain peak sharpness, ensuring your knives remain culinary assets.

Regular maintenance not only preserves the blade’s edge but also extends the knife’s overall lifespan. Learning the right techniques transforms sharpening from a chore into a rewarding skill. This empowers you to keep your tools in optimal condition, ready for any task. 🔪

The Art of Whetstone Sharpening: Techniques for Beginners and Experts

Whetstone sharpening is the traditional and most effective method for maintaining the extreme sharpness of Japanese knives. For beginners, starting with a medium-grit stone (around 1000-2000 grit) and focusing on consistent angle maintenance is key. Many guides recommend using a sharpening angle guide initially to build muscle memory.

Experts often utilize a progression of stones, from coarse (200-400 grit) for significant repair, to medium, and then to very fine (4000-8000+ grit) for a mirror-polished, razor-sharp edge. The technique involves maintaining a precise angle while pushing and pulling the blade across the stone, creating a burr. For detailed recommendations, see our guide on the Best Whetstone for Japanese Knives.

Honing Rods vs. Stropping: Daily Edge Maintenance Essentials

Honing and stropping are vital for daily edge maintenance, distinct from sharpening. A honing rod, typically ceramic or fine steel, realigns a slightly rolled or bent edge without removing significant material. This is a quick fix to restore a knife’s cutting ability between sharpening sessions.

Stropping, using a leather strop with or without abrasive compounds, refines the edge further and removes any microscopic burrs. It polishes the edge to an even finer level, contributing to a truly hair-splitting sharpness. While honing is for realignment, stropping is for ultimate refinement. Both practices contribute significantly to edge longevity.

Proper Storage and Care: Preserving Your Blade’s Edge

Even the sharpest Japanese knife will suffer if not stored and cared for properly. Never store them loosely in a drawer where they can bump against other utensils, as this can chip or dull the delicate edge. Magnetic knife strips, knife blocks, or saya (wooden sheaths) are ideal storage solutions.

Always hand wash your Japanese knives immediately after use with mild soap and water, then dry them thoroughly to prevent rust, especially with high-carbon steels. Avoid dishwashers entirely, as the harsh detergents and high heat can damage the blade and handle. Proper care is paramount for maintaining the keenness of your sharp Japanese knives.

Advanced Steel Metallurgy for Superior Edge Retention

The backbone of truly sharp Japanese knives lies in their advanced steel metallurgy. It’s not just about getting a knife sharp, but keeping it sharp through repeated use. This concept, known as edge retention, is a critical performance metric for any high-quality blade.

Modern steel development, combined with traditional Japanese heat treatment, has pushed the boundaries of what’s possible in cutlery. Understanding these material science concepts provides insight into why certain knives perform exceptionally well and command their price points. 🔬

VG-10 vs. SG2 (R2) vs. Blue/White Steels: A Deep Dive into Performance

The choice of steel profoundly impacts a knife’s performance profile. VG-10 is a popular stainless steel known for its good balance of sharpness, edge retention, and corrosion resistance. It’s often found in mid-range to high-end Japanese knives, offering reliability for everyday use.

SG2 (R2), another powdered stainless steel, offers even greater hardness and edge retention due to its finer grain structure. This allows for a very acute and stable edge, often preferred by professionals. Blue (Aogami) and White (Shirogami) steels, produced by Hitachi Metals, are high-carbon steels prized for their ability to take an exceptionally fine, long-lasting edge, though they require more maintenance.

| Steel Type | Key Characteristics | Edge Retention | Corrosion Resistance | Maintenance |

|---|---|---|---|---|

| VG-10 | Balanced, popular stainless | Good | Excellent | Low |

| SG2 (R2) | High hardness, powdered stainless | Excellent | Very Good | Low |

| Blue Steels | High carbon, very hard | Exceptional | Low | High (rust-prone) |

| White Steels | Purest carbon, extreme sharpness | Exceptional | Very Low | Very High (rust-prone) |

The Impact of Rockwell Hardness (HRC) on Sharpness and Durability

Rockwell Hardness (HRC) is a critical metric for Japanese knives. It measures the steel’s resistance to indentation, directly correlating with its ability to hold a sharp edge. Japanese knives typically range from 60-65 HRC, significantly harder than most Western knives (54-58 HRC).

This higher hardness allows for those extremely acute edge angles and superior edge retention. However, harder steels can also be more brittle, making them susceptible to chipping if mishandled. The art lies in finding the perfect balance between hardness for sharpness and toughness for durability. This balance is a hallmark of truly elite high-end Japanese chef knives.

Beyond the Edge: Unlocking the Molecular Secrets of Japanese Knife Sharpness

To truly appreciate the mastery behind sharp Japanese knives, we must look beyond the visible edge and delve into the microscopic world of steel. The secrets of their unparalleled sharpness and longevity are often found at the molecular level, in the intricate structure of the metal itself. This advanced section explores these hidden depths.

This level of detail is what sets Japanese cutlery apart. It showcases a profound understanding of materials science combined with generations of practical application. It’s a testament to the fact that knife making is both an art and a highly technical science. 🔬

Microstructure of Steel: Carbides, Grains, and Heat Treatment for Ultimate Sharpness

The microstructure of the steel is fundamental to its performance. Tiny, hard carbide particles within the steel matrix are what form the actual cutting edge. The size, distribution, and type of these carbides dictate how fine and stable an edge can be achieved. Smaller, evenly distributed carbides lead to a sharper, more durable edge.

Heat treatment is arguably the most critical step. Precise heating and cooling cycles transform the steel’s crystalline structure, optimizing the formation and distribution of carbides and refining grain size. This controlled process maximizes hardness and toughness, unlocking the steel’s full potential for ultimate sharpness. For an in-depth look at this craftsmanship, see Master crafted handmade Japanese knives.

Proprietary Edge Retention Testing: Real-World Sharpness Longevity Across Brands

While Rockwell Hardness provides a good indication, real-world edge retention testing offers a more comprehensive picture of a knife’s performance. Culinary authorities like Serious Eats often conduct rigorous tests, using standardized methods to compare how well different knives maintain their cutting ability over extended periods of use.

These tests involve repeatedly cutting abrasive materials and measuring the degradation of the edge. Brands like Miyabi and Global invest significantly in such proprietary testing to refine their steel formulations and heat treatment processes. This ensures their knives deliver consistent, long-lasting sharpness that stands up to professional demands. Quantifiable data drives innovation in blade performance.

The Philosophy of Honbazuke: An Artisan’s Perspective on Precision Sharpening

Honbazuke represents the traditional three-phase hand-honing process that gives Japanese knives their legendary sharpness. This philosophy goes beyond mere sharpening; it’s an artisan’s commitment to precision. It involves an initial coarse grind, followed by a fine grind, and culminates in a final polishing step, all meticulously performed by hand on whetstones.

This exacting process ensures not only an incredibly keen edge but also the correct blade geometry for optimal cutting performance. The result is an edge that slices with minimal effort, embodying the very soul of a sharp Japanese knife. It’s a practice that marries skill, patience, and an understanding of the blade’s inherent qualities. It is truly an art form. 🧑🍳

Frequently Asked Questions About Sharp Japanese Knives

Many common questions arise when exploring the world of sharp Japanese knives. This section addresses some of the most pressing inquiries, providing concise and informative answers. Our aim is to clarify doubts and empower you with knowledge. 🎯

Are Japanese knives truly sharper than Western knives?

Yes, generally, Japanese knives are designed to be significantly sharper than most Western knives. This is due to several factors: harder steel allows for more acute edge angles (often 10-15 degrees per side vs. 20-25 degrees), thinner blade stock, and traditional sharpening techniques that yield a finer, more precise edge. This combination results in superior cutting performance and less resistance through ingredients.

How do I choose the sharpest Japanese knife for my needs?

Choosing the sharpest Japanese knife involves considering steel type, HRC rating, and blade geometry. For ultimate sharpness and edge retention, look for knives made with high-carbon steels (Blue, White) or powdered stainless steels (SG2/R2) with an HRC above 60. Also, consider the specific tasks: a Yanagiba for slicing fish will have a different sharpness profile than a Gyuto for general prep. Your specific culinary needs will guide your choice effectively.

What are the best sharpening tools for maintaining Japanese knife sharpness?

The best sharpening tools for maintaining the sharpness of Japanese knives are high-quality whetstones. A good set typically includes a coarse stone (around 400 grit) for repair, a medium stone (1000-2000 grit) for primary sharpening, and a fine finishing stone (4000-8000+ grit) for polishing the edge. Additionally, a leather strop is excellent for daily edge refinement. Honing rods can be used for realignment but don’t actually sharpen the blade.

How much should I expect to pay for a high-quality sharp Japanese knife?

The price range for high-quality sharp Japanese knives can vary significantly. Entry-level quality knives from reputable brands might start around $100-$150. Mid-range professional-grade knives typically fall between $200-$400. High-end, hand-forged, or specialized knives, particularly those with rare steels or intricate finishes (like Honyaki), can easily cost $500 to over $1000. Investment usually correlates with the steel quality, craftsmanship, and performance. Consider your budget and needs.

What’s the difference between ‘razor-sharp’ and ‘edge retention’ in Japanese knives?

“Razor-sharp” refers to the initial, extremely keen cutting ability of a knife’s edge. It describes how effortlessly the knife slices through material straight off the sharpening stone. “Edge retention,” conversely, describes how long that initial razor sharpness lasts under regular use before the blade needs to be sharpened or honed again. Japanese knives excel at both, often achieving superior initial sharpness and maintaining it longer due to their harder steels and precise geometry.

Essential Tools & Resources for Maintaining Sharp Japanese Knives

Maintaining the legendary sharpness of your Japanese knives requires the right tools and continuous learning. Equipping yourself with these essentials will ensure your blades perform at their peak for years to come. This section outlines key items and learning pathways. 📚

Investing in quality maintenance tools is just as important as investing in the knives themselves. It’s a commitment to preserving their value and performance. By embracing these resources, you’re not just maintaining a tool; you’re preserving an art form.

Recommended Whetstone Grits, Sharpening Guides, and Stropping Compounds

For a complete sharpening setup, we recommend a combination whetstone (e.g., 1000/3000 grit) for general sharpening, and a finer finishing stone (6000-8000 grit) for polishing. Sharpening guides can assist beginners in maintaining a consistent angle. For daily refinement, a leather strop with a green or black stropping compound will bring out that mirror polish. These tools form the core of effective edge care.

Authoritative Books, Online Courses, and Communities for Knife Enthusiasts

To deepen your knowledge, explore authoritative books like “The Complete Guide to Sharpening” or “Knife Sharpening Made Easy.” Online courses, often found on platforms like Skillshare or YouTube channels from master sharpeners, provide visual, step-by-step guidance. Engaging with online communities on forums like BladeForums or Reddit’s r/chefknives can offer invaluable tips, product reviews, and peer support. Continuous learning is essential for mastering the art of keeping sharp Japanese knives.

Real-World Impact: The Advantage of Sharp Japanese Knives in Professional Kitchens

The impact of sharp Japanese knives extends far beyond the home kitchen, making a significant difference in professional culinary environments. In a fast-paced setting, efficiency, precision, and consistency are paramount. Japanese cutlery provides a distinct advantage that directly translates into superior results and operational benefits.

These blades are not just preferred; they are often essential tools for chefs aiming for peak performance. Their ability to deliver clean cuts reduces waste and elevates the presentation of dishes. This section explores tangible examples of their transformative power in professional settings. 🚀

Case Study: Achieving Effortless Prep with a Master-Crafted Gyuto

Consider a busy restaurant kitchen where a chef uses a master-crafted Gyuto with an impeccably sharp edge. Tasks like finely dicing onions, julienning carrots, or slicing delicate herbs become effortless. The Gyuto’s superior sharpness means less hand fatigue over long shifts and quicker prep times for multiple mise en place stations.

The precise cuts ensure uniform ingredient size, which is critical for consistent cooking and plating. This level of efficiency, enabled by a truly sharp Japanese knife, directly contributes to smoother kitchen operations and higher quality output, demonstrating its invaluable role in professional culinary artistry. It’s a game-changer for speed and accuracy.

Before & After: The Transformative Power of a Professional Sharpening Service

Many professional kitchens utilize dedicated sharpening services to maintain their extensive knife collections. The “before and after” difference of a professionally sharpened Japanese knife is often astonishing. A dull, struggling blade returns with a hair-splitting edge, making it feel like a brand-new tool. This transformation rejuvenates the entire cutting experience.

This service not only restores peak performance but also ensures the correct angles and geometry are maintained, which can be challenging for busy chefs to achieve consistently. The renewed sharpness directly impacts productivity and food quality. It showcases the importance of expert maintenance for these precision instruments.

Quantifiable Benefits: Reduced Ingredient Waste and Increased Efficiency

The use of sharp Japanese knives offers tangible, quantifiable benefits in professional kitchens. Precise cuts lead to significantly reduced ingredient waste; for instance, a clean slice of fish or vegetable yields more usable product than a torn or mangled one. This directly impacts food costs, a major concern for restaurants.

Increased efficiency is another crucial benefit. Faster, more accurate prep times mean chefs can handle larger volumes of work in less time, improving overall kitchen throughput. Data from various culinary institutions, including the Culinary Institute of America, often highlights how superior tools contribute to both quality and profitability. This makes investing in quality knives a wise economic decision for businesses.

Embracing the Edge: Your Journey to Unparalleled Sharpness with Japanese Knives

The journey into the world of sharp Japanese knives is one of discovery, precision, and continuous learning. These aren’t just cutting tools; they are extensions of the chef’s hand, embodying centuries of tradition and innovation. Embracing their unique qualities unlocks a new level of culinary artistry. 🌟

From understanding the intricate metallurgy to mastering the art of sharpening, every step enhances your appreciation and skill. This commitment to excellence transforms not just your knives, but your entire cooking philosophy. Let’s recap why these blades are a true game-changer.

Key Takeaways: Why Investing in Sharp Japanese Knives is a Game-Changer

Investing in sharp Japanese knives is a game-changer for several compelling reasons. Their superior steel and acute edge angles provide unparalleled cutting performance, making prep work faster, safer, and more enjoyable. They preserve the integrity of ingredients, elevating the taste and presentation of your dishes. Moreover, with proper care and maintenance, these knives become lifelong companions in your culinary endeavors, a true testament to their lasting quality and the rich heritage of Japanese craftsmanship.

Next Steps: Choosing Your Blade and Elevating Your Culinary Craft

Your next step is to carefully consider your needs, budget, and desired cutting tasks. Research different blade types, steel properties, and brands that resonate with your culinary style. Don’t shy away from learning the fundamentals of whetstone sharpening; it’s a rewarding skill that will keep your blades in peak condition. With the right sharp Japanese knives in hand, you’ll not only elevate your culinary craft but also experience a profound connection to the art of cooking. Happy cutting! ✅

🔪 Discover Premium Japanese Knives at JapaneseKnivesWorld

At JapaneseKnivesWorld, we are passionate about authentic Japanese cutlery, helping chefs and cooking enthusiasts discover the finest knives from Japan’s master craftsmen.

⚔️ Curated selection of premium Japanese knives from legendary makers

🗾 Expert guides on Japanese steel types and craftsmanship techniques

📚 Comprehensive reviews and comparisons of top knife brands

🎯 Professional advice for choosing your perfect Japanese knife

Ready to find your perfect Japanese knife?

🔗 Explore our complete buying guides and expert recommendations at JapaneseKnivesWorld.com

Follow us for daily knife insights:

🌐 Website