Achieving peak performance from your culinary tools is paramount, and at the heart of this lies impeccable edge maintenance. Mastering japanese knives sharpening techniques is not merely a chore but a precise art form, essential for preserving the unique characteristics and exceptional cutting ability of these revered blades. This comprehensive guide will delve into every facet, from foundational principles to advanced methodologies, ensuring your Japanese knives retain their legendary sharpness and longevity.

Unveiling the Precision of Japanese Knives Sharpening

The world of Japanese cutlery is defined by a meticulous approach to craftsmanship, a philosophy that extends directly to their maintenance. Unlike their Western counterparts, Japanese knives are often forged from harder steels and possess distinct blade geometries, demanding a specialized understanding for effective japanese knives sharpening. Ignoring these nuances can lead to blade damage or, at best, a subpar edge that diminishes the knife’s true potential.

The Distinctive Metallurgy and Geometry of Japanese Blades

Japanese knives typically utilize high-carbon steels, often with Rockwell hardness ratings exceeding 60 HRC. This exceptional hardness allows for an incredibly fine, keen edge that holds its sharpness longer. However, it also means these blades are less forgiving and require precise angles during japanese knives sharpening to avoid chipping. Many traditional Japanese knives feature asymmetrical, or single-bevel, grinds, a departure from the double-bevel designs common in Western knives. This design choice contributes to their unparalleled precision cutting, especially for tasks like intricate slicing and filleting. Understanding this underlying structure is the first step in effective japanese knives sharpening.

The steel used in these knives, such as Aogami (blue steel) or Shirogami (white steel), offers superior edge retention but can be more brittle. This brittleness necessitates a delicate touch and the correct sharpening medium. The geometry often includes a “shinogi” line, a prominent ridge that defines the primary bevel, and a subtle “urasky” (concave back) on single-bevel knives, both of which are critical to maintain during japanese knives sharpening to preserve the knife’s intended performance. These distinct features, from the steel composition to the blade’s profile, are what make japanese knives sharpening a unique discipline requiring dedicated study and practice.

Why Conventional Sharpening Falls Short for Japanese Knives

Using conventional pull-through sharpeners or electric grinders designed for softer, Western-style knives can severely damage the delicate edges of Japanese blades. These devices often apply excessive force, remove too much material indiscriminately, and are incapable of replicating the precise, shallow angles or asymmetrical grinds characteristic of Japanese knives. The high hardness of Japanese steels means that aggressive, coarse sharpening methods can easily lead to chipping or micro-fractures, fundamentally compromising the blade’s integrity. For example, a common household sharpener might use abrasive wheels that are too coarse or set at an angle too obtuse for the acute edges found on a high-quality Gyuto. This is why dedicated techniques for japanese knives sharpening are not optional, but essential.

Furthermore, traditional Western sharpening often focuses on creating a “toothier” edge for chopping and general utility. Japanese knives, however, are designed for incredibly fine, clean cuts that glide through ingredients, requiring a highly polished, refined edge. The precision required for japanese knives sharpening goes beyond merely making the knife sharp; it’s about restoring its specific cutting geometry and maintaining its unique character. Ignoring these requirements will result in a knife that feels dull quickly, struggles with precise tasks, and ultimately, has a significantly reduced lifespan. A true master of japanese knives sharpening understands that it’s a process of refinement, not brute force.

The Foundational Science of Japanese Knives Sharpening

Behind every perfectly sharp Japanese knife lies a deep understanding of metallurgical principles and edge mechanics. Effective japanese knives sharpening is not just about moving a blade across a stone; it’s about understanding how the steel behaves, how angles influence cutting performance, and the subtle dance between abrasion and refinement. This foundational knowledge empowers you to approach japanese knives sharpening with confidence and precision, ensuring optimal results every time. It bridges the gap between simply sharpening a blade and truly understanding the craft.

Understanding Steel Hardness and Edge Retention in Japanese Blades

The hardness of Japanese knife steel, typically ranging from 60 to 65 HRC, is a double-edged sword: it allows for an extremely keen and durable edge, but it also makes the steel more prone to chipping if mishandled during use or sharpening. Steels like VG-10, SG2/R2, and various Aogami and Shirogami carbon steels are renowned for their ability to take and hold an incredibly fine edge. This high carbon content and specific heat treatment contribute to their superior edge retention. However, it also means that conventional abrasive materials may not be sufficient for effective japanese knives sharpening.

When you sharpen a knife, you are essentially abrading away microscopic layers of steel to form a new, keen apex. With harder steels, this process requires finer abrasives and more consistent pressure to avoid micro-fractures along the edge. The trade-off for superior edge retention is often increased brittleness, meaning that a Japanese knife’s edge, while holding its sharpness for a long time, is also more susceptible to damage from impacts or twisting motions. Therefore, the approach to japanese knives sharpening must be gentle yet firm, focusing on careful material removal and precise angle control to maintain the integrity of the high-carbon steel.

Exploring the different types of steel used in these knives can further enhance your understanding. For more details, consider visiting our types of Japanese knives guide.

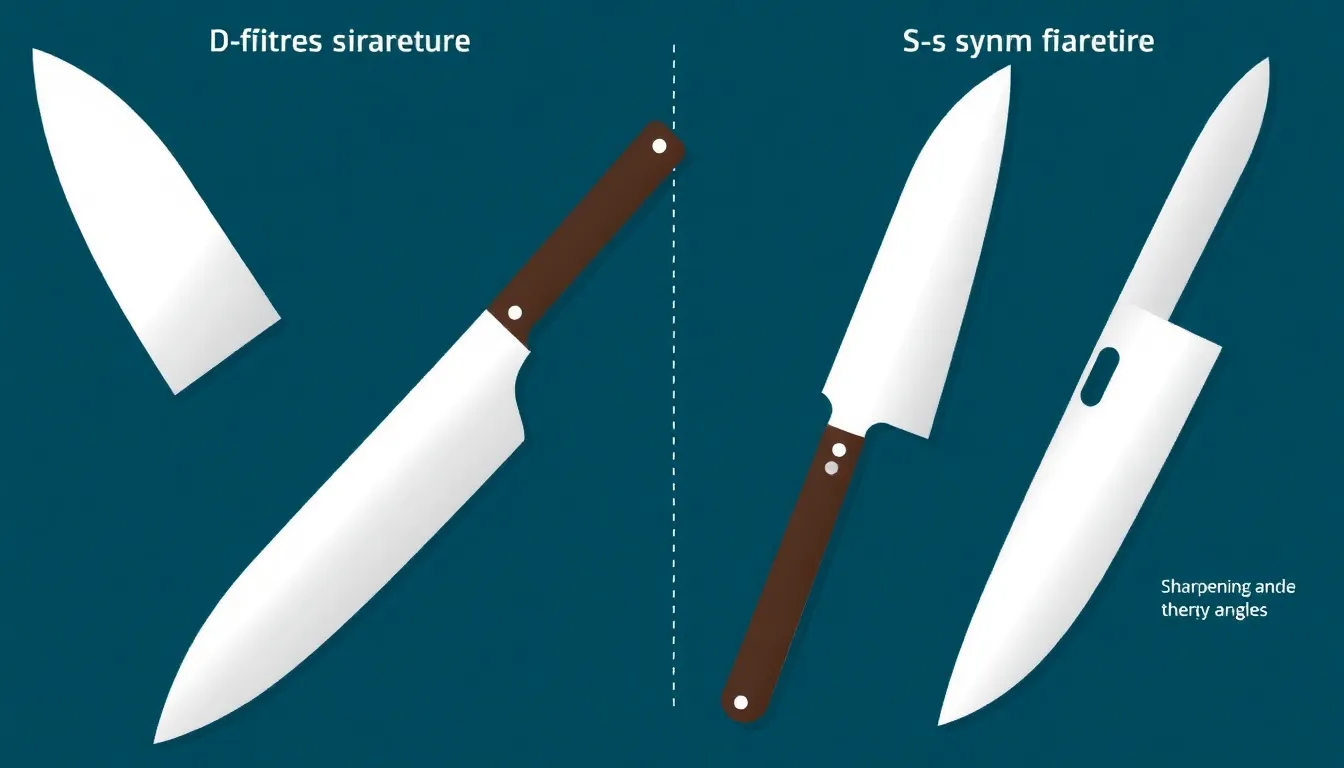

The Role of Blade Geometry: Asymmetrical vs. Symmetrical Edges

Japanese knives exhibit diverse blade geometries, each designed for specific culinary tasks and requiring distinct japanese knives sharpening approaches. Symmetrical, or double-bevel, edges are common on knives like Gyutos and Santokus, where both sides of the blade are ground to an equal angle, creating a V-shaped edge. These are more versatile and are sharpened similarly to Western knives, albeit at much finer angles (typically 10-15 degrees per side compared to 20 degrees or more for Western knives).

Conversely, many traditional Japanese knives, such as Yanagiba (slicers), Deba (fish butchers), and Usuba (vegetable knives), feature asymmetrical, or single-bevel, edges. These knives have a prominent primary bevel on one side and a largely flat or slightly concave back (ura) on the other. This unique design allows for incredibly precise, clean cuts and minimal sticking, particularly important for delicate tasks like preparing sushi. Japanese knives sharpening for single-bevel knives is significantly different, requiring focus primarily on the large primary bevel to set the angle and then delicately refining the ura side to remove the burr and create a subtle secondary bevel, which is critical for the knife’s performance and release properties. Misunderstanding this geometry is a common pitfall in japanese knives sharpening, leading to diminished performance and potentially damaging the blade.

Debunking Common Myths About Japanese Knives Sharpening Angles

One prevalent myth is that all Japanese knives should be sharpened at a single, universal angle. In reality, the optimal angle for japanese knives sharpening varies significantly depending on the knife’s specific design, its intended use, and the type of steel. For instance, a delicate filet knife (Sujihiki) might benefit from an extremely acute angle (around 10-12 degrees per side) for maximum sharpness, while a robust Deba might require a slightly more obtuse angle (15-20 degrees per side) for durability, especially for breaking down fish bones. Another misconception is that a sharper angle always equates to a better knife. While acute angles produce incredibly keen edges, they are also more prone to chipping on harder tasks or with less durable steels. The goal of japanese knives sharpening is not just sharpness, but appropriate sharpness balanced with edge stability.

Another myth suggests that “micro-bevels” are unnecessary for Japanese knives. While the primary bevel sets the main edge, a subtle micro-bevel or a slight increase in angle at the very apex can significantly improve edge durability without sacrificing much sharpness, especially for harder-used knives. Ultimately, the best angle for japanese knives sharpening is one that provides a balance of sharpness and resilience for how the knife will be used. Experimentation and understanding your specific knife are key, rather than blindly following a one-size-fits-all rule. This nuanced approach differentiates amateur attempts from professional japanese knives sharpening results.

Essential Tools for Professional Japanese Knives Sharpening

The right tools are indispensable for achieving professional-grade results in japanese knives sharpening. While a diverse array of sharpening gadgets exists, the traditional whetstone (or water stone) remains the gold standard for Japanese knives. Its ability to gently abrade steel and create incredibly fine, polished edges is unmatched. Investing in quality tools and understanding their proper use is a critical step towards mastering japanese knives sharpening and maintaining the pristine condition of your blades. Beyond the stones themselves, several ancillary items contribute to a more efficient and effective sharpening process.

The Whetstone Spectrum: Grit Selection and Purpose

Whetstones are categorized by their grit rating, which determines the abrasive particle size and, consequently, the fineness of the finish. A comprehensive set for japanese knives sharpening typically includes stones across a spectrum of grits:

- Coarse Grit (120-400): Used for significant edge repair, correcting chips, or establishing a new bevel. These stones remove material quickly but leave a very rough finish. They are rarely used for routine japanese knives sharpening unless the knife is severely damaged.

- Medium Grit (800-2000): The workhorse stones for routine japanese knives sharpening. They effectively remove minor dullness and refine the edge established by coarser stones, preparing it for finer grits. This is where the majority of your time will be spent during a sharpening session.

- Fine Grit (3000-8000): Used for polishing the edge, removing burrs, and creating a razor-sharp finish. These stones create a highly refined edge that glides through ingredients. A 3000-5000 grit stone is often sufficient for most kitchen tasks, while higher grits are for extreme refinement.

- Super Fine/Finishing Grit (10,000+): For those seeking the absolute pinnacle of sharpness and polish, often used for specialist knives like Yanagiba. These stones produce a mirror-like edge, ideal for delicate slicing.

The progression from coarser to finer grits is crucial for effective japanese knives sharpening. Each successive stone removes the scratches left by the previous one, gradually refining the edge until it reaches its ultimate keenness. Skipping grits can lead to an inferior edge that dulls quickly. For a deeper dive into choosing the right stones, check out our guide on whetstone guide. A reputable brand like King Whetstones (Japaneseknifesharpening.com sells King, Naniwa, Shapton etc.) is a good starting point for quality whetstones for japanese knives sharpening.

Ancillary Sharpening Tools: Flattening Stones, Nagura, and Strops

Beyond the primary whetstones, several other tools enhance the japanese knives sharpening process:

- Flattening Stone (Nagura Stone or Lapping Plate): Whetstones wear down with use, developing concave surfaces that hinder consistent angle maintenance. A flattening stone, often a coarse silicon carbide stone or a diamond lapping plate, is essential for keeping your whetstones perfectly flat. This ensures even contact with the blade and prevents “dishing” which can compromise your sharpening results. Maintaining flat stones is a non-negotiable aspect of successful japanese knives sharpening.

- Nagura Stone: A small, fine stone used with softer whetstones to create a slurry on the surface. This slurry, a paste of abrasive particles and water, helps suspend new abrasive particles, improving the cutting action of the whetstone and providing a smoother feel. It’s particularly useful for finer grit stones.

- Leather Strop with Polishing Compound: After sharpening on the finest whetstone, stropping is the final step to refine the edge and remove any microscopic burr. A leather strop, often charged with chromium oxide paste, polishes the edge to an incredible keenness, making it razor-sharp. This step significantly extends the “shaving sharp” life of your blade. It’s the ultimate finishing touch for perfect japanese knives sharpening.

- Angle Guides: While not strictly necessary for experienced sharpeners, angle guides can be invaluable for beginners learning to maintain consistent angles during japanese knives sharpening. They clip onto the spine of the knife and provide a stable reference point against the stone.

Each of these tools plays a specific role in ensuring precision and quality throughout the japanese knives sharpening process, contributing to a superior edge and extending the life of your blades.

Creating the Optimal Sharpening Environment

A conducive environment is crucial for effective japanese knives sharpening. You’ll need a stable, non-slip surface to place your whetstones. A rubber mat or a wet towel underneath the stone can prevent it from sliding during sharpening, which is both dangerous and detrimental to angle consistency. Adequate lighting is also essential; a well-lit workspace allows you to clearly see the burr forming and the progress of your edge. Furthermore, having a constant water supply is key, as most Japanese whetstones require continuous hydration during use to maintain their cutting efficiency and prevent clogging. A spray bottle or a small bowl of water kept nearby is ideal. Some people prefer sharpening near a sink for easy access to running water and cleanup. Ensuring a comfortable posture will also help maintain consistency over longer sharpening sessions. An organized and clean workspace will not only make the japanese knives sharpening process safer but also more enjoyable and efficient, leading to better results and a more positive experience. A clutter-free area allows you to focus solely on the intricate details of the blade and stone.

Mastering the Art of Whetstone Sharpening for Japanese Knives

Whetstone sharpening is where the true artistry of japanese knives sharpening lies. It requires patience, practice, and a keen sense of touch. The goal is not just to abrade metal but to meticulously sculpt the edge, ensuring perfect symmetry (for double-bevel) or precise geometry (for single-bevel) and an exceptionally keen apex. This section will guide you through the fundamental steps to transform a dull blade into a razor-sharp instrument, ready for the demands of the kitchen. Every stroke, every angle, contributes to the final outcome.

The Hydration Ritual: Preparing Your Whetstones for Action

Most traditional Japanese whetstones are “soaking” stones and require complete saturation before use. This process, often referred to as the hydration ritual, is critical for optimal japanese knives sharpening. Immerse your stone fully in water until bubbles cease to rise, which can take anywhere from 5 to 15 minutes depending on the stone’s density and size. This saturation prevents the stone from drying out too quickly during sharpening, which can lead to a less effective cutting action and premature wear. Some modern whetstones, like resin-bonded or splash-and-go stones, only require a quick splash of water on the surface, but always refer to the manufacturer’s instructions. During the sharpening process, it’s vital to keep the stone’s surface consistently wet, either by splashing water on it or by having a continuous drip. A dry stone will clog with swarf (metal particles and abrasive dust) and lose its cutting ability, potentially scratching the blade. Proper hydration ensures that new abrasive particles are continuously exposed, maximizing the stone’s efficiency and providing a smooth, consistent feel, which is paramount for effective japanese knives sharpening.

The slurry that forms on the surface of a wet stone also plays a crucial role. This abrasive paste helps to suspend fine particles, enhancing the cutting action and providing a cushioning effect that helps achieve a more refined edge. Learning to work with this slurry is an integral part of mastering japanese knives sharpening. Neglecting proper hydration is a common beginner’s mistake that significantly hampers results.

Achieving Consistent Angles: The Core of Effective Japanese Knives Sharpening

Maintaining a consistent angle throughout the entire length of the blade is arguably the most challenging and critical aspect of japanese knives sharpening. Even a slight wobble can create an uneven edge that quickly dulls or chips. For double-bevel knives, the goal is to consistently maintain the desired angle (e.g., 10-15 degrees) against the stone. Start by finding the knife’s existing bevel angle; you can do this by marking the bevel with a marker and then making a few light passes on a fine stone. Adjust your angle until the marker is evenly removed. Once you’ve found the angle, try to lock your wrist and arm, moving your entire body as a unit to glide the blade across the stone. Use gentle, even pressure, focusing on feeling the edge contact the stone. Practice is key here, and many beginners use angle guides to help develop muscle memory. Visual cues, such as the reflection of light off the edge, can also help you determine if your angle is consistent. For single-bevel knives, the process is different: you’ll primarily sharpen the main bevel at its natural angle, then delicately address the ura side to remove the burr. Mastering this consistency is the hallmark of skilled japanese knives sharpening, leading to edges that not only cut well but also hold their sharpness longer.

There are various techniques for holding the knife, such as the “finger-on-spine” grip or the “thumb-on-blade” grip, each offering different levels of control and feedback. Experiment to find what works best for your hand size and the knife in question. Consistent angle is far more important than a specific angle, as long as it’s within the general range appropriate for the knife’s type and use. This skill is the foundation upon which all advanced japanese knives sharpening techniques are built, allowing you to achieve true edge perfection.

Burr Formation and the Delicate Art of Deburring

As you sharpen, tiny metallic fragments will push to the opposite side of the blade, forming a microscopic wire-edge known as a “burr.” Feeling for this burr (gently, with your fingertip) is your primary indicator that you have fully sharpened one side of the blade down to the edge. Once a continuous burr is formed along the entire length of one side, you then switch to the other side of the blade (for double-bevel knives) and repeat the process until a burr forms there as well. The delicate art of deburring is crucial for japanese knives sharpening. This process involves carefully removing the burr without damaging the newly formed, keen edge. Techniques include very light, high-angle passes on the fine grit stone, stropping, or using a very light “feathering” pass on the final stone. For single-bevel knives, the ura side is gently laid flat on the finest stone for a few extremely light passes to remove the burr without creating a secondary bevel. An improperly removed burr will result in an edge that feels sharp initially but dulls almost instantly with the first cut. Therefore, recognizing and meticulously removing the burr is a fundamental skill in achieving a truly lasting and exceptionally keen edge through japanese knives sharpening.

Some sharpeners prefer to use progressive burr reduction, where they alternate sides with fewer and lighter strokes as they move to finer grits, gradually shrinking the burr until it can be removed with a final few passes. This meticulous attention to burr management is what separates a good sharpening job from an outstanding one, ensuring that the knife reaches its peak performance. For optimal blade longevity, consistent burr removal is paramount. It prevents chipping and rolls, common issues in poorly maintained edges. Maintaining proper blade care extends beyond sharpening. Learn more about it in our knife care guide.

Specialized Techniques for Unique Japanese Knife Geometries

The diverse range of Japanese knife styles necessitates specialized japanese knives sharpening techniques. A one-size-fits-all approach will not yield optimal results, particularly for traditional single-bevel knives. Understanding the unique characteristics of each blade type and adapting your sharpening method accordingly is a hallmark of advanced japanese knives sharpening skill. This section will delve into the specific considerations for some of the most iconic Japanese knife geometries, ensuring each blade receives the precise care it deserves to perform at its peak.

Single-Bevel Blades: Sharpening Yanagiba, Deba, and Usuba

Sharpening single-bevel knives like the Yanagiba (slicing knife), Deba (fish butchering knife), and Usuba (vegetable knife) is a distinctly different process compared to double-bevel blades, and it represents a higher level of skill in japanese knives sharpening. These knives have a primary bevel on one side (the “omote” side) and a slightly concave or flat back (the “ura” side) that facilitates release from food.

- Omote (Primary Bevel) Sharpening: Place the knife on the stone so that the entire omote bevel is flat against the surface. The goal is to set and refine this primary angle. Use consistent pressure and move the knife across the stone, focusing on forming a burr along the entire length of the ura side. This typically takes the majority of the sharpening time. Progress through grits as usual, from coarse to fine, ensuring the burr is present before moving to the next stone. Maintaining the proper angle for the omote is crucial for the knife’s cutting performance.

- Ura (Back) Sharpening: This is the most delicate part of japanese knives sharpening for single-bevels. The ura side should be laid completely flat on the fine finishing stone. Apply extremely light pressure, using just a few passes (1-3 passes per grit) to gently remove the burr that formed on the omote side. The goal is not to create a new bevel, but merely to flatten the back and refine the edge. Over-sharpening the ura can ruin the knife’s unique geometry and stick it to food. Some experts even recommend using only the weight of the blade. The ura side’s integrity is vital for food release and straight cutting.

Mastering the balance between omote and ura sharpening is essential for preserving the unique performance characteristics of single-bevel knives. This nuanced approach makes japanese knives sharpening for these blades a truly rewarding challenge. Achieving the proper balance will allow the knife to glide through ingredients with minimal friction, a hallmark of these specialized tools.

The Nuances of Thin-Bladed Gyutos and Santokus

Gyutos (chef’s knives) and Santokus (general-purpose knives) are the workhorses of the Japanese kitchen. While they are double-bevel knives, their typically thinner blades and harder steels require more attention during japanese knives sharpening than their Western counterparts. The acute angles (often 10-15 degrees per side) they are sharpened at make them incredibly sharp but also more susceptible to chipping if too much pressure is applied or if the angle is inconsistent.

- Consistent Light Pressure: Due to their thinness and hardness, applying excessive pressure can cause the edge to flex or micro-chip. Use lighter, more controlled pressure than you might for a softer, thicker knife. Let the stone do the work.

- Angle Precision: Because the bevels are so acute, even small deviations in angle can significantly impact performance. Focus intently on maintaining a steady angle throughout the stroke, paying particular attention to the tip and heel where angles can vary.

- Thinning (Optional but Recommended): Over time, repeated sharpening can cause the area just behind the edge to thicken, making the knife wedge in food. This is often called “shouldering.” Periodically, thinning the blade above the edge is necessary for these knives. This involves grinding a wider, shallower bevel higher up the blade to restore its original geometry. This is an advanced japanese knives sharpening technique performed on a coarser stone, typically 400-800 grit, and requires a very light touch to avoid damaging the blade. Thinning is crucial for maintaining the “laser-like” cutting performance that these knives are known for.

By paying attention to these subtleties, you can ensure your Gyutos and Santokus remain incredibly keen and perform as intended for their entire lifespan. Neglecting these nuances can lead to a knife that feels sharp at the edge but still struggles to cut efficiently through denser ingredients, indicating a need for more advanced japanese knives sharpening techniques like thinning. Understanding these finer points will greatly enhance your overall japanese knives sharpening capabilities.

Troubleshooting Common Edge Irregularities During Japanese Knives Sharpening

Even with practice, you might encounter issues during japanese knives sharpening. Recognizing these common irregularities and knowing how to correct them is part of becoming proficient:

- Uneven Edge/Flat Spots: If your edge isn’t continuous or has dull spots, it typically means your angle was inconsistent or you weren’t hitting the entire edge of the blade on the stone. Go back to a medium grit stone, re-evaluate your angle, and ensure every part of the edge makes contact with the stone during each stroke. Use a marker on the edge to visualize contact points.

- Micro-chips or Rolled Edge: This can occur from too much pressure, an angle that’s too acute for the steel or task, or impacts during use. For micro-chips, you’ll need to go back to a coarser grit (400-800) to grind past the chip, then re-establish the edge through progressive grits. A rolled edge often indicates the burr wasn’t fully removed or the angle was too shallow; re-sharpen on a medium stone, focusing on burr formation and removal.

- Edge Wedging (Shouldering): As mentioned, this happens when the blade thickens behind the edge from repeated sharpening. The solution is thinning, which involves creating a new, wider primary bevel further up the blade, reducing the thickness behind the edge. This is an advanced technique performed on a coarser stone and requires careful monitoring of the blade’s geometry.

- Insufficient Sharpness: If the knife isn’t as sharp as desired, it’s usually due to an incomplete burr removal, skipping grits, or not spending enough time on finer stones. Ensure a full burr is formed at each grit, and dedicate sufficient time to the polishing stages.

Patience and methodical troubleshooting are key. Each irregularity offers a learning opportunity, refining your touch and understanding of the blade and stone dynamics. The journey to mastering japanese knives sharpening is iterative, with each challenge bringing you closer to perfection. Consistent feedback from the edge and careful observation are your best tools for identifying and correcting these issues. For more advanced sharpening techniques, consider exploring resources on blade geometry and custom bevels.

Beyond the Edge: Maintenance and Longevity of Japanese Knives

Achieving a razor-sharp edge through dedicated japanese knives sharpening is only half the battle. Maintaining that edge and ensuring the longevity of your valuable Japanese knives requires diligent post-sharpening care and responsible storage. A sharp knife is a safe knife, but a well-cared-for knife is an enduring tool that will serve you for decades. This section focuses on the practices that extend the life and performance of your blades far beyond the sharpening board, cementing the overall mastery of japanese knives sharpening and care. Every detail, from cleaning to storage, plays a vital role in preserving these culinary treasures.

Post-Sharpening Care: Cleaning, Drying, and Storage

Immediately after japanese knives sharpening, meticulous cleaning and drying are essential. Swarf (the mixture of steel particles and abrasive from the stone) can be corrosive, especially to carbon steel knives. Rinse the knife thoroughly under cool water to remove all slurry and abrasive particles. Do not use harsh detergents, as they can strip away any protective oils or patinas. After rinsing, immediately and thoroughly dry the knife with a clean, soft cloth. Leaving even a tiny amount of moisture on a carbon steel blade can lead to rust spots, which can be challenging to remove. Stainless or clad knives are more forgiving but still benefit from immediate drying. Once dry, consider applying a thin layer of food-safe mineral oil to carbon steel blades, especially if they are not used daily. This provides an additional barrier against moisture and corrosion. Proper storage is equally critical. Avoid storing Japanese knives loosely in a drawer where they can bump against other utensils, which will dull or chip the delicate edge. Magnetic knife strips, knife blocks, in-drawer knife organizers, or saya (wooden sheaths) are ideal storage solutions that protect the edge and prevent accidental damage. Proper care significantly extends the time between major japanese knives sharpening sessions.

Consistency in these post-sharpening rituals is key. Make it a habit to clean, dry, and store your knives correctly after every use, not just after sharpening. This proactive approach will minimize the need for extensive repairs and maintain the knife’s pristine condition, making future japanese knives sharpening easier and more effective. A knife that is well-cared for will also develop a beautiful patina over time, especially carbon steel blades, adding to its character and history.

Strop Sharpening: The Secret to Sustaining Razor Sharpness

Stropping is a vital, often overlooked, step in maintaining the razor sharpness achieved through japanese knives sharpening. It’s not a sharpening process in itself but rather a polishing and alignment technique. After sharpening on your finest stone, microscopic burrs and wire edges may still remain, and the very apex of the edge may be slightly misaligned. Stropping removes these remnants and polishes the edge to an incredibly keen, mirror-like finish. Use a leather strop, ideally charged with a fine abrasive compound like chromium oxide (green compound). Place the knife flat on the strop with the edge facing away from you, and pull the knife backwards (spine leading) along the strop. Never push the edge into the strop, as this can roll or damage it. Perform several passes on one side, then flip the knife and do the same on the other side. You’ll feel the blade become smoother and sharper with each pass. Regular stropping (even daily, depending on use) can significantly extend the time between full whetstone japanese knives sharpening sessions, keeping your knives hair-popping sharp with minimal effort. It’s the ultimate method for maintaining that “shaving sharp” edge that is the hallmark of a well-maintained Japanese knife.

Stropping is particularly beneficial for delicate tasks where ultimate sharpness is paramount, such as slicing raw fish for sushi or thinly dicing herbs. It helps to re-align any minor deformations that occur during cutting without removing significant amounts of steel, thus prolonging the life of your blade. Integrating stropping into your routine is a simple yet profoundly effective way to uphold the quality of your japanese knives sharpening efforts. It refines the edge to a level that simply cannot be achieved with whetstones alone, making the knife truly glide through ingredients.

Recognizing When Professional Japanese Knives Sharpening is Necessary

While mastering japanese knives sharpening yourself is highly rewarding, there are times when seeking professional assistance is warranted.

- Significant Damage: If your knife has large chips, a bent tip, or a severely rolled edge that you can’t correct with your current skill level or tools, a professional can often restore it. They have access to specialized equipment and expertise for major repairs.

- Thinning Needs: As mentioned, thin-bladed Japanese knives can develop “shoulders” over time, making them feel dull despite a sharp edge. Thinning is an advanced technique that requires significant skill and experience. If you’re uncomfortable attempting it yourself, a professional sharpener specializing in Japanese knives can perform this crucial maintenance.

- Single-Bevel Restoration: Restoring the intricate geometry of single-bevel knives like Yanagiba or Usuba can be particularly challenging. If you find yourself unable to achieve the desired performance, a professional who understands these complex grinds can be invaluable.

- Lack of Time or Confidence: If you simply don’t have the time, patience, or confidence to embark on the journey of mastering japanese knives sharpening, a reputable professional can ensure your knives are always in top condition.

When choosing a professional, look for someone who specifically advertises experience with Japanese knives and whetstone sharpening. Ask about their methods and experience with different knife types. While DIY japanese knives sharpening is empowering, knowing when to call in the experts ensures your valuable knives remain in peak condition throughout their lifetime. A truly skilled professional can even correct issues that seem irreversible, bringing your beloved blade back to life. They possess the knowledge of various steel types and blade geometries, ensuring the most appropriate sharpening method is applied.

The Enduring Legacy of Japanese Knives Sharpening

The journey of mastering japanese knives sharpening is a continuous pursuit of perfection, a blend of scientific understanding and tactile artistry. It’s a skill that deepens your appreciation for the craftsmanship of these extraordinary tools and enhances your culinary experience immeasurably. A truly sharp knife is safer, more efficient, and transforms cooking from a chore into a joy. By embracing the principles and techniques outlined in this guide, you are not just sharpening a knife; you are upholding a centuries-old tradition of precision and care that defines Japanese cutlery. The ongoing practice of japanese knives sharpening connects you to a rich heritage of craftsmanship and a relentless pursuit of edge perfection.

Recapitulating the Principles of Edge Mastery

The core tenets of effective japanese knives sharpening can be summarized as follows:

- Understand the Blade: Recognize the unique metallurgy and geometry (single vs. double bevel) of your specific Japanese knife.

- Choose the Right Tools: Invest in quality whetstones across a range of grits, along with essential ancillary tools like a flattening stone and a strop.

- Master the Angle: Consistency in angle is paramount. Practice until you can reliably maintain the correct angle for the entire blade length.

- Hydrate and Slurry: Keep your stones properly hydrated and understand the role of the abrasive slurry in the sharpening process.

- Burr Management: Learn to identify the burr and, more importantly, to meticulously remove it without damaging the fresh edge.

- Refine and Polish: Progress through finer grits and finish with stropping to achieve the ultimate keenness and edge polish.

- Maintain and Protect: Regular cleaning, immediate drying, proper storage, and routine stropping are crucial for edge longevity.

By internalizing these principles, you gain the confidence and capability to consistently achieve and maintain a superior edge on all your Japanese knives, ensuring they perform at their absolute best. Each principle builds upon the last, forming a comprehensive approach to japanese knives sharpening that yields exceptional results. The satisfaction of a perfectly sharpened knife is a reward in itself, a testament to your dedication and skill in japanese knives sharpening.

The Ongoing Journey to Perfecting Your Japanese Knives Sharpening Skills

Mastering japanese knives sharpening is not a destination but a lifelong journey. There is always more to learn, more nuanced techniques to refine, and new steels and blade geometries to understand. Embrace the learning process, be patient with yourself, and view every sharpening session as an opportunity to improve. Seek out advanced resources, watch reputable sharpening videos, and perhaps even join a local sharpening workshop. Pay attention to how your knives perform after sharpening – this feedback is invaluable for adjusting your technique. The tactile experience of the stone against the steel, the sound of the slurry, and the feeling of a hair-popping sharp edge are all part of the rewarding process. As you progress, you’ll develop a deeper connection with your tools and a profound appreciation for the craft of Japanese cutlery. Your skill in japanese knives sharpening will not only benefit your knives but also enhance your overall culinary proficiency and enjoyment. Keep practicing, keep learning, and your Japanese knives will reward you with unparalleled performance for years to come. The pursuit of the perfect edge is a testament to the enduring legacy of japanese knives sharpening, a skill that transforms good cooks into great culinary artists. It’s a skill that resonates with the precision and artistry inherent in Japanese culture itself.

Explore More on Japanese Knives World:

Ready to delve deeper into the world of Japanese knives and their care? Visit our blog for more insights and guides: