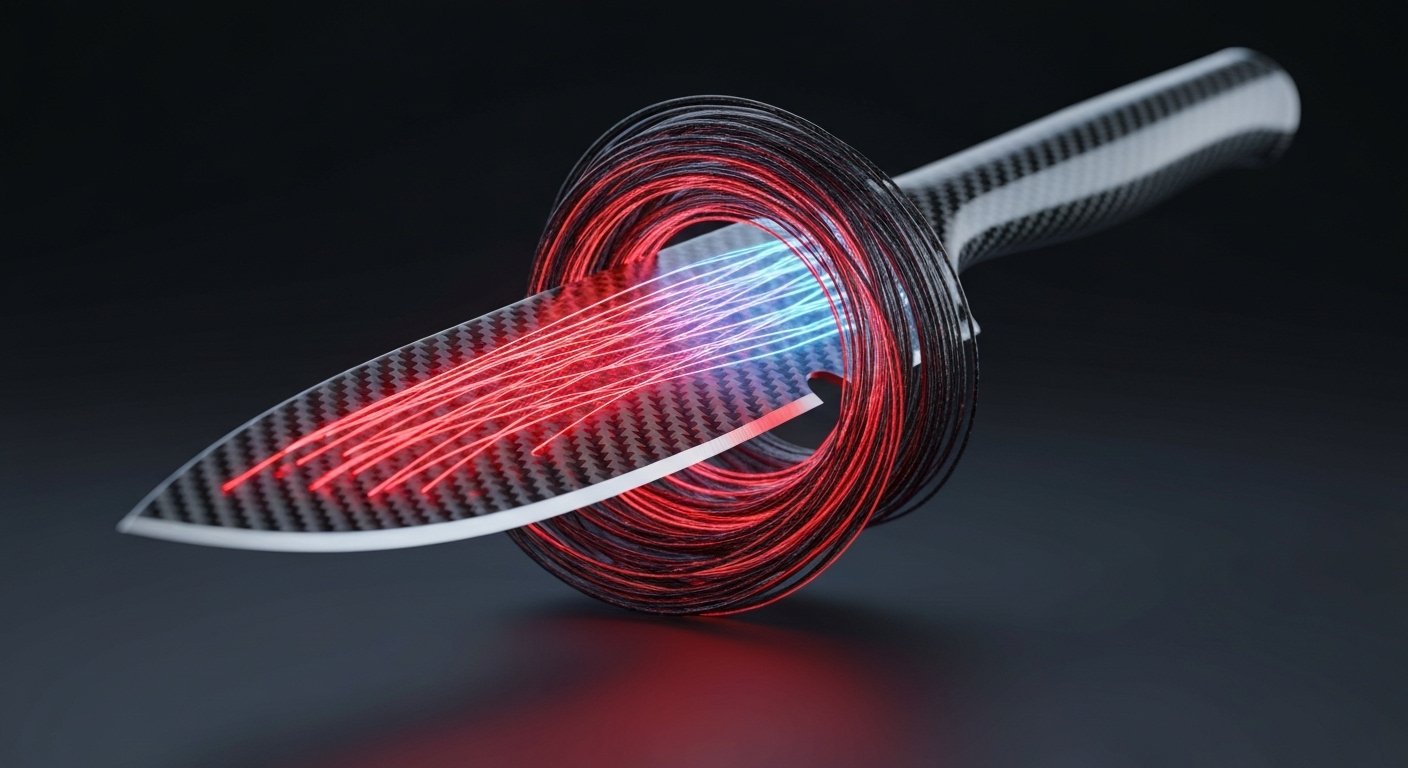

The culinary world is constantly evolving, with new materials and technologies promising to revolutionize the way we prepare food. Among these advancements, the concept of a carbon fiber kitchen knife has garnered significant attention, often surrounded by a mix of excitement and skepticism. Many aspiring chefs and home cooks envision a blade that is incredibly light, impossibly sharp, and virtually indestructible. This article aims to cut through the hype and provide a definitive look at carbon fiber’s true utility and limitations in the kitchen.

Unveiling the Carbon Fiber Kitchen Knife Enigma

The Allure of Advanced Materials in the Culinary World

The appeal of advanced materials in kitchen tools is undeniable. Chefs and home cooks alike are always seeking an edge, whether it’s improved sharpness, lighter weight, or enhanced durability. This constant pursuit drives innovation, leading to exploration of materials beyond traditional steel.

From aerospace to automotive industries, carbon fiber has proven its mettle in applications demanding high strength-to-weight ratios. Its remarkable properties naturally spark curiosity about its potential in demanding culinary environments.

The perception of carbon fiber as a “space-age” material often leads to exaggerated expectations when applied to everyday tools like kitchen knives. It suggests a future where our implements are lighter, stronger, and more efficient than ever before.

Setting the Record Straight: Why Carbon Fiber Isn’t What You Think

Despite its reputation in other fields, carbon fiber’s direct application as a blade material for a carbon fiber kitchen knife is fraught with significant challenges. The very properties that make it desirable elsewhere can become liabilities in the kitchen.

Understanding the fundamental nature of carbon fiber, its composition, and how it behaves under stress is crucial. This knowledge helps demystify the material and clarify why it hasn’t replaced steel in high-performance kitchen cutlery.

We will delve into the realities, separating fact from fiction regarding the feasibility and practicality of a pure carbon fiber blade. This exploration will highlight why your ideal kitchen knife still likely features a steel or ceramic edge.

The Fundamental Flaws of Carbon Fiber as a Kitchen Knife Blade Material

While carbon fiber excels in many structural applications, its inherent characteristics pose significant hurdles when considered for a kitchen knife blade. The requirements for a cutting edge are very specific, and carbon fiber simply doesn’t meet them effectively.

Unlike homogeneous metals, carbon fiber is a composite material, which impacts its ability to form and hold a fine, durable edge. This fundamental difference is critical to understanding its limitations in culinary tools.

The challenges extend beyond simple edge performance to issues of brittleness, sharpening, and even food safety. These factors collectively explain why you rarely see a true carbon fiber kitchen knife blade in professional settings.

Edge Retention and Brittleness: A Duel with Culinary Demands

One of the primary drawbacks of using carbon fiber for a knife blade is its poor edge retention. Carbon fiber composites are made of strong, stiff fibers embedded in a resin matrix.

When sharpened, these fibers can fray rather than form a cohesive, sharp edge, leading to a blade that quickly loses its initial keenness. This fraying makes it difficult to achieve the micro-fine edge necessary for precision cutting in the kitchen.

Furthermore, carbon fiber, while strong in tension, is inherently brittle when subjected to impact or lateral forces. A delicate knife edge, particularly one that needs to withstand chopping motions, would be highly susceptible to chipping and breaking.

Imagine a kitchen knife chipping during routine dicing or cleaving – this brittleness renders it impractical for the diverse demands of a busy kitchen. Steel, by contrast, has a degree of toughness and ductility that allows it to absorb impact without catastrophic failure.

This inherent brittleness means a carbon fiber kitchen knife blade would be prone to micro-fractures, significantly reducing its lifespan and reliability in a professional environment. It simply cannot withstand the rigorous use that a chef expects from their tools.

Sharpening Challenges: Maintaining a Practical Edge on Carbon Fiber

Sharpening a carbon fiber blade presents another significant obstacle. Traditional sharpening methods, designed for metals, are largely ineffective and potentially damaging to carbon fiber composites.

The abrasive nature of sharpening stones can tear and splinter the carbon fibers rather than creating a smooth, refined edge. This leads to a jagged, ineffective cutting surface that struggles with even simple tasks like slicing tomatoes.

Specialized diamond abrasives might be able to abrade the material, but achieving a consistent and fine burr, essential for a truly sharp knife, would be incredibly challenging. The composite nature means varying hardness across the cutting surface.

For a chef who relies on a razor-sharp edge throughout their workday, a blade that is difficult or impossible to resharpen quickly and effectively is a non-starter. Regular maintenance is crucial for any high-performance kitchen tool.

This difficulty in maintenance severely limits the practicality of a carbon fiber kitchen knife as a long-term culinary implement. Its inability to be easily restored to peak performance makes it ill-suited for the demands of daily use.

Food Safety & Hygiene: Porosity, Particle Shedding, and Cleaning Concerns

Food safety and hygiene are paramount in any kitchen, and carbon fiber presents potential issues in this regard. The resin matrix in carbon fiber composites can be porous, potentially harboring bacteria and food particles.

This porosity makes proper sanitation a challenge, as residues can become trapped within the material, leading to cross-contamination risks. Unlike non-porous stainless steel or ceramic, which are easy to sanitize, carbon fiber requires more careful consideration.

Another concern is the potential for particle shedding. As the blade is used and potentially wears down, microscopic carbon fibers could theoretically detach and contaminate food. While the health implications of such exposure are not fully understood, it’s a risk most chefs would prefer to avoid.

The nature of the composite material might also react differently with various food acids or chemicals present in cleaning agents. This could lead to degradation of the blade material over time, further compromising its integrity and hygiene.

Considering the strict health and safety regulations in commercial kitchens, the potential for porosity and particle shedding makes a carbon fiber kitchen knife a questionable choice for food preparation surfaces. Reliability and cleanliness are non-negotiable.

Debunking Common Misconceptions About Carbon Fiber Kitchen Knives

The mystique surrounding carbon fiber often leads to inflated claims about its capabilities in the culinary sphere. Many popular beliefs about a carbon fiber kitchen knife simply don’t align with the material’s actual properties when applied to cutting tools.

These misconceptions stem from a misunderstanding of how carbon fiber functions as a composite and how its strength is best utilized. It’s not a magic material that excels at everything equally.

By addressing these myths head-on, we can gain a more realistic perspective on what carbon fiber can and cannot do for your kitchen arsenal. This clarity is essential for making informed purchasing decisions.

Myth 1: Unrivaled Sharpness and Indestructible Durability

One prevalent myth is that a carbon fiber kitchen knife can achieve unrivaled sharpness and maintain an edge indefinitely. The reality is quite different due to the very nature of the material.

As discussed, carbon fiber’s composite structure makes it incredibly difficult to hone to a truly fine, consistent edge. The individual fibers, while strong, do not align in a way that creates a single, continuous cutting surface.

Instead, the edge tends to be microscopic serrations or breaks at the fiber-resin interface, leading to a perceived initial sharpness that quickly diminishes. This is a far cry from the enduring sharpness of high-quality steel or ceramic blades.

Furthermore, the idea of “indestructible durability” is also misleading. While carbon fiber has high tensile strength, it lacks the toughness and impact resistance required for a knife blade.

It is prone to chipping, splintering, and brittle fracture when subjected to the torsional and impact forces common in kitchen use. Dropping a carbon fiber blade on a hard floor would likely result in irreparable damage, unlike a resilient steel knife.

Therefore, any claim of a carbon fiber kitchen knife being superior in both sharpness and durability to traditional materials is largely unfounded and ignores the practical realities of material science.

Myth 2: The Ultimate Lightweight Blade for Effortless Slicing

The lightweight nature of carbon fiber is often touted as a major advantage, promising effortless slicing and reduced fatigue. While carbon fiber is indeed light, this benefit doesn’t automatically translate to an “ultimate” blade.

For some applications, excessive lightness can actually be a disadvantage in a knife. Many chefs prefer a certain amount of heft and balance in their knives for controlled, precise cuts and to aid in chopping tasks.

A very light blade might feel less stable in the hand, requiring more effort to guide through denser foods. The momentum of a slightly heavier blade can assist in cleanly slicing through ingredients like squash or root vegetables.

While a lightweight handle is desirable for ergonomics, a lightweight blade can sometimes make certain cutting techniques more challenging, particularly for professional chefs accustomed to the feel of a traditional knife. Balance is key, not just minimum weight.

The pursuit of the absolute lightest knife isn’t always the pursuit of the best performing knife. An optimal kitchen knife balances weight, strength, and edge performance, a combination that a pure carbon fiber kitchen knife struggles to achieve for the blade itself.

Myth 3: Superior to Steel for All Cutting Tasks and Longevity

This myth suggests that a carbon fiber kitchen knife somehow surpasses steel in every aspect of cutting performance and lifespan. This is a broad generalization that ignores the vast range of steel alloys and their tailored properties.

High-carbon stainless steels, powdered metallurgy steels, and even traditional carbon steels are engineered to optimize a specific balance of hardness, toughness, edge retention, and corrosion resistance. Brands like Shun, Wüsthof, and Zwilling J.A. Henckels spend generations perfecting their blade materials.

For longevity, a well-maintained steel knife can last a lifetime, capable of being sharpened countless times. Its resilience against impacts and ability to be easily repaired make it a durable workhorse.

Carbon fiber, conversely, as a blade material, would likely have a shorter functional lifespan due to its brittleness and sharpening difficulties. Once a carbon fiber blade chips significantly, it’s often irreparable or uneconomical to repair.

Steel offers unparalleled versatility across all cutting tasks, from delicate slicing to heavy-duty chopping, due to its ability to be forged and heat-treated for specific applications. A carbon fiber kitchen knife simply cannot match this adaptability or long-term value.

Therefore, claiming carbon fiber’s superiority across the board is a profound oversimplification that disregards the sophisticated metallurgy behind modern knife steels and the practical realities of kitchen work. For a true understanding of knife materials, explore our knife materials guide.

The Anatomy of Carbon Fiber – What It Is (and Isn’t) for Knives

To truly understand the limitations of a carbon fiber kitchen knife, it’s essential to grasp what carbon fiber actually is and how it’s manufactured. It’s not a homogeneous metal, but a complex composite material.

This understanding helps explain why its fantastic properties in some applications don’t directly translate to ideal blade performance. The way its components are assembled dictates its overall characteristics.

Differentiating between pure carbon fiber, carbon fiber composites, and carbon fiber as a cosmetic layer is crucial for setting realistic expectations for its use in kitchen cutlery. Most “carbon fiber” knives are not what they seem.

Composition and Manufacturing: From Filaments to Functional Forms

Carbon fiber is primarily composed of extremely thin strands of carbon atoms, typically 5–10 micrometers in diameter. These strands are much thinner than a human hair and are incredibly strong in tension.

To create a functional material, these individual fibers are woven into a fabric, similar to cloth. This fabric is then impregnated with a resin, most commonly an epoxy, and cured under heat and pressure.

This process results in a carbon fiber reinforced polymer (CFRP), which is the material we commonly refer to as carbon fiber. It’s a composite, meaning it’s made from two or more constituent materials with significantly different physical or chemical properties, which remain separate and distinct at the macroscopic or microscopic level within the finished structure.

The strength of the final product comes from the carbon fibers providing stiffness and tensile strength, while the resin matrix binds the fibers together, protects them, and transfers loads between them.

This layered, composite structure is fundamentally different from a solid, monolithic material like steel. This difference is critical when considering its application as a cutting edge for a carbon fiber kitchen knife.

The manufacturing process allows for incredible design flexibility in shapes and forms, making it ideal for aerospace parts or racing car components where specific stresses are managed. However, a cutting edge presents very localized and intense stress.

Key Material Properties: Strength-to-Weight Ratio, Rigidity, and Heat Tolerance

Carbon fiber’s most celebrated property is its exceptional strength-to-weight ratio. It can be significantly stronger and stiffer than steel at a fraction of the weight, making it highly desirable for applications where weight saving is paramount, like aircraft or high-performance bicycles.

Its high rigidity means it resists bending and deformation under load, contributing to structural integrity. This stiffness is excellent for frames and structural components, but for a blade, it contributes to brittleness rather than flexibility.

In terms of heat tolerance, the resin matrix is typically the limiting factor. Standard epoxy resins used in carbon fiber composites can begin to degrade at relatively low temperatures compared to steel, usually around 200-300°F (93-150°C), though higher-temperature resins exist.

While this might not be an immediate issue for a cold cutting knife, prolonged exposure to high heat, such as that near a stove or dishwasher’s drying cycle, could potentially affect the resin’s integrity over time. Steel blades, conversely, are heat-treated at much higher temperatures and are generally impervious to typical kitchen heat.

These properties make carbon fiber excellent for certain structural applications, but they do not automatically qualify it as an ideal material for a carbon fiber kitchen knife blade. The specific demands of a cutting edge are unique.

Differentiating Carbon Fiber Composites vs. Pure Carbon Fiber Blades

It’s crucial to distinguish between a knife made entirely of carbon fiber composite as a blade, and a knife that simply features carbon fiber in its construction, often for cosmetic or handle purposes. A truly “pure” carbon fiber blade is virtually nonexistent in functional kitchen knives.

What is sometimes marketed as a “carbon fiber knife” often refers to a blade made of steel with a carbon fiber veneer or coating. This is done purely for aesthetic appeal, giving the knife a modern, high-tech look without altering the underlying blade material’s performance.

Alternatively, the term might refer to a composite blade where carbon fiber is an additive to another material, like a ceramic matrix, but this is rare and experimental for kitchen use. These are highly specialized and not typical of what consumers expect.

The vast majority of knives featuring carbon fiber will use it for the handle material. This is where carbon fiber truly excels in cutlery, enhancing ergonomics and aesthetics without compromising blade performance.

Understanding this distinction is vital to avoid being misled by marketing. A genuine carbon fiber kitchen knife blade, as a primary cutting edge, faces significant material limitations that prevent widespread adoption in professional or even serious home kitchens.

Where Carbon Fiber Truly Shines in Kitchen Knives – The Handle Revolution

While carbon fiber struggles as a blade material, it finds its true calling and widespread acceptance in kitchen knives as a handle material. This is where its unique properties genuinely enhance the tool.

The attributes that make it problematic for a cutting edge – light weight, rigidity, and aesthetic appeal – become significant advantages when applied to the hilt of a knife. This revolutionizes knife ergonomics and design.

From custom knifemakers to major manufacturers, carbon fiber handles are becoming increasingly popular for their practical benefits and distinctive appearance. This is the real place for a carbon fiber kitchen knife to shine.

Aesthetic Appeal and Customization: The Look of Modern Carbon Fiber

One of the most immediate draws of carbon fiber handles is their striking aesthetic. The woven pattern of the fibers, often visible beneath a clear resin, provides a unique, modern, and high-tech look that is instantly recognizable.

This distinctive visual texture sets carbon fiber handles apart from traditional wood, plastic, or even micarta. It adds a premium, sophisticated touch to any kitchen knife, appealing to those who appreciate contemporary design.

The material can also be manipulated during manufacturing to create various patterns and finishes, allowing for a high degree of customization. This enables knife manufacturers and custom makers to produce visually stunning and unique pieces.

From a purely stylistic perspective, a carbon fiber kitchen knife handle can elevate the overall appearance of the tool, making it a statement piece in a culinary collection. It’s a blend of form and function where aesthetics genuinely contribute to desirability.

The ability to integrate colored fibers or resins further expands customization possibilities, allowing for personalized designs. This visual versatility is a significant factor in its popularity for high-end kitchen knives.

Ergonomics and Weight Balance: Benefits of Carbon Fiber Handles

Beyond aesthetics, carbon fiber handles offer substantial ergonomic advantages. Their low weight can significantly improve the overall balance of a knife, especially when paired with a heavier steel blade.

A well-balanced knife reduces fatigue during prolonged use, allowing for greater control and precision. The light weight of the handle shifts the balance point closer to the blade, where many chefs prefer it for optimal maneuverability.

This improved balance can make even large chef’s knives feel more agile and less cumbersome, enhancing the user experience. For professionals spending hours in the kitchen, this can be a game-changer.

Carbon fiber’s rigidity also contributes to a stable and solid feel in the hand, without adding unnecessary bulk. This ensures a firm grip and prevents flexing, which is crucial for safety and cutting accuracy.

The ability to mold carbon fiber into complex, ergonomic shapes allows manufacturers to design handles that fit comfortably in the hand, further improving grip and reducing strain. This thoughtful design for a carbon fiber kitchen knife handle makes a real difference.

Enhanced Grip and Durability for Kitchen Knife Components

Carbon fiber handles are remarkably durable and resistant to many of the common issues that plague other handle materials. Unlike wood, they are impervious to moisture, preventing warping, cracking, or bacterial growth.

They are also significantly more resistant to impacts and scratches than many plastics or softer composite materials. This makes them ideal for the harsh, fast-paced environment of a professional kitchen.

The texture of carbon fiber, particularly when finished with a slight texture, can offer a surprisingly good grip, even when wet. This is critical for safety in a kitchen where hands might be slippery from food or water.

Its resistance to chemicals found in cleaning agents or food acids also contributes to its longevity and ease of maintenance. A carbon fiber kitchen knife handle will retain its integrity and appearance much longer than many alternatives.

This combination of enhanced grip, superior durability, and low maintenance makes carbon fiber an ideal material for kitchen knife handles. It truly contributes to the knife’s overall performance and longevity where it matters most.

Beyond Carbon Fiber: Exploring Cutting-Edge Materials for Kitchen Knife Blades

While the direct application of a carbon fiber kitchen knife blade remains largely impractical, the quest for superior cutting performance continues. This has led to significant advancements in other blade materials, primarily advanced steels and ceramics.

Understanding these alternatives provides context for why they dominate the high-performance knife market. They offer a proven balance of characteristics that carbon fiber cannot replicate for a cutting edge.

The future of kitchen knives lies in continuous innovation in metallurgy and material science, driven by the real-world needs of culinary professionals and enthusiasts. Explore more about knife types on our kitchen knives category page.

Advanced Stainless Steels: From VG-10 to SG2 and Powdered Metallurgy

Modern metallurgy has revolutionized stainless steel, moving far beyond the basic formulations of yesteryear. Today’s advanced stainless steels offer incredible edge retention, toughness, and corrosion resistance.

VG-10, a Japanese stainless steel, is renowned for its excellent balance of hardness, sharpness, and ease of sharpening. It’s often found in premium Japanese knives from brands like Global and Tojiro, providing a significant upgrade over softer steels.

SG2 (Super Gold 2), also known as R2, is a powdered metallurgy stainless steel that represents another leap forward. Powdered metallurgy processes create a much finer, more homogenous grain structure in the steel, leading to exceptional edge retention and sharpness.

These steels achieve hardness ratings that allow for incredibly thin and sharp edges without sacrificing undue toughness. They can withstand the rigors of professional use and are relatively easy to maintain with proper sharpening techniques.

Other advanced stainless steels, like AUS-10, CTS-XHP, and various CPM (Crucible Particle Metallurgy) steels, continue to push the boundaries of performance. These materials are engineered precisely for knife blades, optimizing properties that a carbon fiber kitchen knife blade simply cannot achieve.

The continuous development in steel alloys ensures that traditional materials remain at the forefront of high-performance kitchen cutlery, proving their adaptability and enduring superiority for cutting tasks.

High-Performance Ceramic Blades: Advantages, Limitations, and Specific Uses

Ceramic blades, typically made from zirconium dioxide (zirconia), offer an alternative to steel with their own unique set of advantages and limitations. They are incredibly hard, often significantly harder than even the toughest steels.

This extreme hardness translates into exceptional edge retention; a ceramic knife can hold its sharpness for a very long time, requiring less frequent sharpening. They are also completely non-reactive, making them ideal for delicate ingredients like fruits and vegetables that might oxidize with steel.

Brands like Kyocera are well-known for their ceramic kitchen knives. These knives are also very lightweight, similar to the imagined benefit of a carbon fiber kitchen knife, contributing to reduced hand fatigue.

However, ceramic blades are notoriously brittle. They are highly susceptible to chipping and breaking if dropped, twisted, or used on hard surfaces like bones or frozen foods. Once chipped, they are very difficult to resharpen properly, often requiring specialized diamond sharpeners or professional services.

Therefore, while excellent for specific, precise slicing tasks, ceramic knives are not all-purpose workhorses like steel knives. Their brittleness limits their versatility in a busy kitchen environment where diverse cutting needs arise.

Emerging Technologies: What the Future Holds for Kitchen Knife Blade Innovation

The field of materials science is constantly evolving, and the future of kitchen knife blades may hold even more innovative solutions. Researchers are exploring various novel composites and advanced manufacturing techniques.

One area of interest is advanced ceramic-matrix composites, which aim to combine the hardness of ceramics with improved toughness. However, these are still largely in experimental stages and far from mainstream kitchen application.

Another direction involves new forms of amorphous metals or bulk metallic glasses, which have unique atomic structures that could offer exceptional combinations of strength, hardness, and elasticity. While exciting, their production remains complex and expensive.

The integration of nanotechnology might also lead to blade materials with enhanced properties at the molecular level, offering improved edge retention or self-healing capabilities, though this is still largely theoretical for practical knives.

While the allure of a full carbon fiber kitchen knife blade might persist, the practical innovations are more likely to come from refinements of existing material categories or entirely new material science breakthroughs. The focus remains on achieving a functional balance of sharpness, durability, and user-friendliness.

We can expect to see continued improvements in powdered steels, advanced heat treatments, and perhaps novel ceramic formulations that address current brittleness issues. The goal will always be to enhance real-world performance for the chef.

A Professional’s Portfolio: Choosing Your Next High-Performance Kitchen Knife

For any serious cook, choosing the right kitchen knife is a critical decision. It’s an investment in performance, efficiency, and safety. Understanding the nuances of materials goes far beyond the surface appeal of a “carbon fiber kitchen knife.”

A professional’s portfolio of knives is curated for specific tasks, and each blade is chosen for its optimal performance characteristics. This section guides you through the considerations for making informed choices.

It’s about prioritizing function and longevity over fleeting trends or misconceptions about exotic materials. The best knife is one that performs reliably, day in and day out, for the tasks it was designed for.

Prioritizing Blade Material, Hardness, and Edge Geometry for Optimal Performance

When selecting a high-performance kitchen knife, the blade material is paramount. High-carbon stainless steels like VG-10, AUS-10, and powdered metallurgy steels (SG2, ZDP-189) offer a superb balance of edge retention, corrosion resistance, and relative ease of sharpening.

Hardness, measured on the Rockwell scale (HRC), directly correlates with edge retention. A harder steel will hold an edge longer but can be more brittle and harder to sharpen. Professional chefs often seek blades in the 58-64 HRC range for optimal balance.

Edge geometry is equally critical. A thinner blade with a steeper, more acute edge angle (e.g., 15 degrees per side for Japanese knives) will slice through food with less resistance than a thicker, more obtuse edge.

Consider the intended use: a delicate santoku for vegetables benefits from a thin, hard blade, while a robust chef’s knife for general tasks needs a bit more toughness. For more on sharpening and care, visit our knife care tips.

Don’t be swayed by buzzwords like “super steel” without understanding the full implications of its properties. A well-designed blade with proven steel will always outperform a material like a pure carbon fiber kitchen knife blade, no matter how “advanced” it sounds.

Handle Materials: Balancing Aesthetics with Practicality and Comfort in the Kitchen

While the blade gets most of the attention, the handle is where the user connects with the knife. Handle material significantly impacts comfort, grip, balance, and hygiene.

Traditional materials like wood (e.g., Pakkawood, Rosewood) offer classic aesthetics and a warm feel, but require more maintenance and can be prone to cracking if not properly cared for. Modern stabilized woods reduce these issues.

Synthetic materials like Micarta, G10, and indeed, carbon fiber, offer excellent durability, moisture resistance, and provide a secure grip, even when wet. These materials are highly favored for their low maintenance and stability.

Carbon fiber, in particular, combines lightweight properties with striking visual appeal and excellent durability. It’s an increasingly popular choice for high-end kitchen knives precisely because of these benefits.

Ergonomics are key: the handle should fit comfortably in your hand, allowing for a secure grip without causing hot spots or fatigue during extended use. Test different shapes and sizes to find what feels right for you.

Ultimately, a good handle should be hygienic, durable, and provide a comfortable, non-slip grip, making a knife featuring a carbon fiber kitchen knife handle an excellent choice for modern kitchens.

Understanding Maintenance and Longevity for Your High-End Kitchen Tools

Investing in high-quality kitchen knives means committing to their proper maintenance. This ensures their longevity and continued peak performance.

Regular sharpening is crucial. This doesn’t mean grinding away significant material, but rather honing the edge with a ceramic rod or strop regularly to maintain keenness. When the knife starts to drag, it’s time for a proper sharpening on stones.

Proper cleaning and storage are also vital. Always hand wash your knives immediately after use with mild soap and water, then dry them thoroughly. Never put high-quality knives in a dishwasher, as the harsh detergents and high heat can damage both blades and handles.

Store knives safely in a knife block, magnetic strip, or knife roll to protect the edge and prevent accidental damage. Proper storage prevents dulling and chipping that can occur from contact with other utensils.

Understanding the specific needs of your blade material – whether it’s a high-carbon stainless steel that needs occasional oiling or a ceramic blade that requires delicate handling – will extend its life.

A well-maintained knife, even if it’s not a mythical pure carbon fiber kitchen knife blade, will outperform and outlast an expensive knife that is neglected. Longevity comes from care as much as from material quality.

The Enduring Legacy of the Kitchen Knife

Recalibrating Expectations for Carbon Fiber in Culinary Applications

It’s clear that while carbon fiber is a marvel of modern engineering, its role in a carbon fiber kitchen knife is best suited for handle construction, not the blade itself. The material’s inherent properties, particularly its brittleness and difficulty in forming a stable edge, make it unsuitable for direct cutting applications.

We must recalibrate our expectations, moving beyond the sensational claims often associated with advanced materials. The allure of “space-age” technology doesn’t always translate to practical culinary benefits when it comes to the cutting edge.

Instead, carbon fiber offers significant advantages in ergonomics, aesthetics, and durability when applied to knife handles. This is where its true value lies in the kitchen, enhancing the user experience without compromising cutting performance.

The best kitchen knives are born from a thoughtful combination of the right materials for each component, ensuring that every part contributes optimally to the knife’s overall function. This balanced approach is critical for truly high-performance tools.

Embracing materials for where they truly excel, rather than forcing them into roles they are ill-suited for, is the path to meaningful innovation in kitchen cutlery. This pragmatism defines the discerning chef’s approach.

The Future of Kitchen Knife Innovation: Focusing on Function, Not Just Flair

The future of kitchen knife innovation will continue to be driven by a focus on functional improvements, rather than merely aesthetic flair. While a beautiful knife is desirable, its primary purpose is to cut effectively and safely.

This means continued refinement in metallurgy for steel blades, exploring new heat treatment protocols, and potentially developing hybrid materials that combine the best properties of different elements.

For handle materials, the trend towards durable, hygienic, and ergonomic synthetics, including carbon fiber, will likely persist and expand. Comfort and control are paramount for any tool used for extended periods.

Blade geometry and grinding techniques will also see continued evolution, seeking to minimize cutting resistance and maximize edge retention through precise engineering. The quest for the perfect balance of sharpness and durability is ongoing.

Ultimately, the best kitchen knives of the future will be those that embody a harmonious blend of cutting-edge materials, thoughtful design, and superior craftsmanship, all geared towards enhancing the culinary experience.

The legacy of the kitchen knife is one of continuous improvement, driven by the practical needs of chefs and home cooks, proving that true innovation is always rooted in function and performance, not just the flashy promise of a carbon fiber kitchen knife blade.

Explore more about Japanese knives and their unique features on our blog: https://japaneseknivesworld.com/