The culinary world is a vast ocean of techniques, ingredients, and, most importantly, tools. Among these tools, the knife stands paramount, an extension of the chef’s hand and will. When it comes to precision, durability, and artistry, the debate of german knives vs japanese knives is a tale as old as time, representing two distinct philosophies in blade craftsmanship.

Understanding the fundamental differences between german knives vs japanese knives is not merely an academic exercise; it’s a critical journey for any aspiring chef, home cook, or knife enthusiast seeking to optimize their kitchen performance. These distinctions delve deep into their heritage, materials, design, and intended use, shaping the very way we approach food preparation.

Unveiling the Culinary Blade Divide

A Legacy of Edge: The Global Impact of German and Japanese Knives

German knife making boasts a heritage rooted in centuries of industrial prowess, particularly in regions like Solingen, often dubbed the “City of Blades.” Brands such as Wüsthof and J.A. Henckels have become synonymous with robustness, durability, and a workhorse mentality in kitchens worldwide.

Their design philosophy emphasizes resilience and versatility, making them a staple in professional kitchens and home settings alike. The broad appeal of German knives lies in their dependable performance across a wide range of culinary tasks, from chopping tough root vegetables to breaking down poultry.

Conversely, Japanese knife making tradition is steeped in the ancient art of sword smithing, dating back millennia. This legacy has imbued Japanese knives with an almost spiritual reverence for precision, sharpness, and aesthetic beauty.

Regions like Seki City are renowned for their intricate craftsmanship, producing blades that are often considered works of art. Brands like Shun, Global, and Masamoto exemplify the pursuit of an unparalleled edge and refined cutting experience. The meticulous attention to detail in every aspect of their design is evident, from the blade’s profile to the handle’s balance.

Beyond Sharpness: Why Understanding Knife Philosophy Matters

While sharpness is a universal desire for any kitchen knife, the philosophies behind german knives vs japanese knives diverge significantly beyond this common goal. German knives are designed for durability and ease of maintenance, built to withstand the rigors of a busy kitchen.

Their robust construction and softer steel allow for greater forgiveness against accidental impacts or improper cutting techniques. This makes them highly approachable for general culinary use and ideal for those who prefer a more forgiving tool.

Japanese knives, on the other hand, prioritize extreme sharpness and precision. Their harder steel and acute edge angles enable exceptionally clean cuts, making them ideal for delicate tasks that demand finesse, such as slicing sashimi or finely dicing herbs. This precision comes with a trade-off, however, requiring more careful handling and specific sharpening techniques.

Understanding these underlying philosophies helps users make an informed choice, aligning their knife selection with their personal cooking style, preferred maintenance routine, and the specific culinary tasks they most frequently perform. It’s about choosing a tool that complements one’s approach to food preparation, rather than simply opting for the sharpest blade.

The Foundational Artistry: Blade Geometry and Construction

German Knives: Robust Full Bolsters and Rocker Profiles

The hallmark of many German knives is their distinctive blade geometry, characterized by a substantial, full bolster. This bolster is the thick piece of steel found at the heel of the blade, where it meets the handle.

It provides several functional benefits, including added weight for a more robust feel, protection for the fingers by creating a physical barrier, and improved balance by shifting the knife’s center of gravity towards the handle. This design ensures durability and a secure grip.

German knife blades typically feature a pronounced curve, known as a “rocker profile,” from the heel to the tip. This curvature facilitates a rocking motion during chopping, which is a common technique used for quickly dicing vegetables and herbs.

The broad profile of these blades, combined with their rocker, makes them exceptionally well-suited for heavy-duty tasks where power and momentum are more critical than delicate precision. This geometry is optimized for the traditional Western cutting style.

The thickness of German blades tends to be greater than their Japanese counterparts, contributing to their robustness and ability to withstand impact. This thicker spine provides stability and strength, preventing flexing during demanding tasks.

This design choice directly reflects the German emphasis on durability and the ability to perform a wide array of kitchen tasks without concern for fragility. It’s a design built for resilience in a demanding environment.

Japanese Knives: Precision Thin Blades and Varied Grind Styles

In stark contrast, Japanese knives are celebrated for their exceptionally thin blades, which are a direct contributor to their renowned sharpness and precision. These thinner profiles minimize friction when cutting, allowing the blade to glide through ingredients with remarkable ease.

The reduced blade thickness also allows for more acute edge angles, which translate to a razor-sharp cutting experience. This design is paramount for delicate tasks such as filleting fish or intricate vegetable preparation.

Japanese knives also feature a diverse range of grind styles, each optimized for specific cutting performance. While Western knives typically feature a double-bevel (V-shape) edge, Japanese knives often incorporate both double-bevel and single-bevel designs.

Single-bevel blades, like those found on yanagiba or deba knives, are ground only on one side, creating an incredibly sharp and precise edge ideal for specific tasks such as slicing fish for sushi. This asymmetric grind allows for unparalleled straight cuts and fine control.

Even double-bevel Japanese knives often have a finer and more precise grind than their German counterparts. The convex or hollow grind techniques employed in some Japanese blades further reduce friction and enhance cutting ability. This meticulous approach to blade geometry is a cornerstone of Japanese knife artistry.

Hand Forged vs. Stamped: Manufacturing Philosophies

The manufacturing process also highlights a significant philosophical divide between german knives vs japanese knives. Historically, many premium German knives are forged from a single piece of steel, heated and hammered into shape.

Forging creates a denser, stronger blade with a full tang that extends through the handle, contributing to superior balance and durability. This traditional method results in a robust and long-lasting tool, often associated with a higher quality and price point.

Stamped knives, on the other hand, are cut from a sheet of steel and then ground and sharpened. While less expensive to produce, they generally lack the heft and durability of forged knives. Many entry-level German knives and utility blades are stamped.

Japanese knives, particularly traditional ones, often involve highly intricate hand-forging techniques, sometimes by master blacksmiths using ancient methods. This includes layering different steels (e.g., Damascus steel) to combine hardness with flexibility and visual appeal.

The multi-step forging process, including differential hardening, is common in Japanese knife making, producing a blade with a super-hard edge and a softer, more resilient spine. This balance allows for extreme sharpness without brittleness.

While mass-produced Japanese knives also exist and can be stamped or machine-forged, the pinnacle of Japanese knife craftsmanship almost invariably involves extensive handwork and meticulous attention to every stage of the forging process.

The Heart of the Blade: Steel Metallurgy and Hardness

The Toughness of German Steel: X50CrMoV15 and Lower HRC

The vast majority of high-quality German knives are crafted from a specific type of stainless steel known as X50CrMoV15. This designation refers to its composition: approximately 0.5% carbon (C), 15% chromium (Cr), and traces of molybdenum (Mo) and vanadium (V).

The relatively lower carbon content (compared to Japanese steels) contributes to its softer nature, typically resulting in a Rockwell Hardness (HRC) rating of around 56-58. This lower HRC makes German blades more flexible and less prone to chipping.

The higher chromium content ensures excellent corrosion resistance, making these knives highly resistant to rust and staining, even with minimal care. This ease of maintenance is a significant advantage for busy kitchens and home cooks.

While not as hard as Japanese steel, X50CrMoV15 is incredibly tough. This toughness means the blade is more resistant to bending or breaking under stress. It also allows the edge to “roll” rather than chip when encountering hard surfaces, which can be easily corrected with a honing rod.

This steel composition reflects the German emphasis on durability, robustness, and ease of use in everyday kitchen environments. It’s a pragmatic choice for a workhorse knife that can handle varied tasks without constant worry about damage.

The Hardness of Japanese Steel: VG-10, SG2, and High HRC Ratings

Japanese knives frequently utilize various high-carbon stainless steels or even pure carbon steels, designed for extreme sharpness and edge retention. Common stainless alloys include VG-10, SG2 (also known as R2), and AUS-10.

These steels contain a significantly higher carbon content than X50CrMoV15, leading to much higher HRC ratings, typically ranging from 60-65 HRC. This superior hardness allows for a much finer and more acute edge angle, resulting in unparalleled sharpness.

VG-10 (V-Gold 10) is a popular choice, renowned for its excellent balance of hardness, edge retention, and corrosion resistance. It often forms the core layer in Damascus-clad blades, offering a superb cutting experience.

SG2 (Super Gold 2) is a powder metallurgy steel, meaning it’s produced by compacting powdered metal, which allows for an incredibly uniform grain structure. This leads to exceptional hardness (often 63-65 HRC) and phenomenal edge retention.

While these harder steels offer superior sharpness and edge retention, they are also more brittle than German steels. They are more susceptible to chipping if dropped or used improperly, requiring more careful handling and specific knife care routines.

The use of these advanced steels underscores the Japanese pursuit of ultimate cutting performance and a razor-sharp edge. It’s a testament to their dedication to pushing the boundaries of what a kitchen knife can achieve.

The Impact of Carbon Content and Alloying Elements

The carbon content in steel is directly responsible for its hardness and ability to hold an edge. Higher carbon content allows the steel to be heat-treated to a greater hardness, resulting in a sharper and longer-lasting edge.

However, higher carbon also makes the steel more brittle and susceptible to rust if it lacks sufficient chromium. This is why traditional carbon steel Japanese knives require meticulous care to prevent corrosion.

Chromium is added primarily for corrosion resistance, forming a protective oxide layer on the steel surface. German steels have a higher percentage of chromium, making them more “stainless” and forgiving in humid environments or when exposed to acidic foods.

Molybdenum increases toughness and strength, particularly at high temperatures, and improves corrosion resistance. Vanadium helps with grain refinement, leading to a finer, more uniform steel structure, which improves strength and edge retention.

Cobalt, tungsten, and other elements are often added to Japanese steels to further enhance properties like hardness, wear resistance, and the ability to achieve a very fine grain. The precise balance of these alloying elements is what defines the performance characteristics of different blade steel types.

Understanding these metallurgical differences provides crucial insight into the performance characteristics of german knives vs japanese knives, explaining why they behave so differently in terms of edge retention, toughness, and maintenance requirements.

Edge Mastery: Angles, Retention, and Sharpening

German Knife Angles: Broad and Durable for Everyday Use

German knives typically feature a wider edge angle, usually ranging from 20 to 25 degrees per side, totaling 40-50 degrees. This broader angle results in a more robust and durable edge that is less prone to chipping or rolling.

This durability makes German knives incredibly versatile and forgiving for everyday kitchen tasks, including chopping through tougher ingredients like squash or frozen foods (though generally not recommended). They are built to withstand a certain degree of abuse.

While not as acutely sharp as their Japanese counterparts, the edge on German knives is perfectly adequate for the vast majority of culinary needs. They provide a reliable cut that holds up well under consistent heavy use.

The wider angle also means they are easier to maintain and re-sharpen for the average home cook. A few passes on a honing rod can realign a rolled edge and restore much of its cutting performance, making them very user-friendly.

This design choice reflects a pragmatic approach to knife utility, prioritizing longevity and ease of maintenance over extreme, but potentially fragile, sharpness. It aligns with the workhorse philosophy of German blade design.

Japanese Knife Angles: Acute and Razor-Sharp for Precision Cuts

Japanese knives are renowned for their incredibly acute edge angles, typically ranging from 10 to 15 degrees per side, resulting in a total angle of 20-30 degrees (for double-bevel knives). Single-bevel knives can have even more acute angles on their cutting side.

This super-sharp, thin edge allows for unparalleled precision and minimal resistance when cutting. It glides through ingredients with extraordinary ease, creating clean, precise cuts that are essential for tasks like preparing sashimi or delicate garnishes.

The acute angle also enables the blade to retain its sharpness for a significantly longer period between sharpenings, assuming proper use and care. This is a primary reason why chefs praise Japanese knives for their superior edge retention.

However, this extreme sharpness comes at a cost: the edge is more delicate and prone to chipping if mishandled or used on hard surfaces. Japanese knives require a higher degree of skill and care in their use and maintenance.

The design philosophy here is to achieve the absolute best cutting performance possible, even if it means sacrificing some degree of raw durability. It’s a tool for precision, demanding respect and expertise from its user.

Sharpening Methodologies: Honing Rods vs. Whetstones for Each Type

The difference in steel hardness and edge angles dictates distinct sharpening methodologies for german knives vs japanese knives. German knives, with their softer steel and wider edge angles, benefit greatly from regular use of a honing rod.

A honing rod (often steel or ceramic) does not remove steel but rather realigns the microscopic edge of the blade that has bent or “rolled” during use. This simple process can quickly restore the knife’s cutting ability without extensive sharpening.

While honing rods are excellent for daily maintenance, German knives will eventually need to be sharpened on a whetstone or using a pull-through sharpener to restore the true edge. This process is generally less frequent than for Japanese knives.

Japanese knives, due to their harder steel and acute, often more brittle edges, should rarely, if ever, be used with a steel honing rod, as this can cause chipping. Instead, they require careful and precise sharpening on whetstones.

Whetstones, available in various grits, gently abrade the steel to create a new, razor-sharp edge. This method allows for precise control over the angle and can achieve the incredibly fine edges that Japanese knives are known for.

Sharpening Japanese knives on whetstones is an art form that takes practice and patience, but it yields unparalleled results. It’s a meditative process that connects the user to the blade, ensuring its peak performance and longevity.

Ergonomics and User Experience: Handle Design and Balance

Western-Style Handles: Full Tang and Bolstered Comfort for German Knives

German knives, and Western knives in general, predominantly feature a full-tang construction with riveted handles. A full tang means the steel of the blade extends the entire length of the handle, providing superior strength, balance, and durability.

The handle scales, typically made from synthetic materials like POM (polyoxymethylene) or sometimes wood, are riveted to the tang. This creates a sturdy and robust grip that is comfortable for prolonged use.

Western-style handles are often ergonomically shaped to fill the hand, offering a secure and comfortable grip for a variety of cutting techniques, including the rocking chop. They tend to be heavier and provide a solid, reassuring feel in hand.

The full bolster, characteristic of many German knives, also contributes to the handle’s comfort and safety. It acts as a natural finger guard, preventing the hand from slipping onto the blade, and provides a comfortable pinch grip point for enhanced control.

The overall design prioritizes robustness and a familiar, comforting feel for broad appeal and ease of use in a wide range of kitchen environments. It’s a design focused on functional, no-nonsense utility.

Wa-Style Handles: Traditional Japanese Design and Balance Points

Japanese knives often feature traditional “Wa-style” handles, which are typically made from wood (such as magnolia, ebony, or rosewood) and come in various shapes like octagonal, D-shaped, or oval. These handles are often lighter than Western handles and are “hidden tang,” meaning the tang does not extend fully through the handle.

Wa-style handles prioritize balance, finesse, and a unique aesthetic appeal. Their lighter weight shifts the knife’s balance point further towards the blade, allowing for more precise control and less wrist fatigue during delicate tasks.

The traditional octagonal or D-shaped handles are designed to offer an excellent grip, especially for the pinch grip favored by many professional chefs. They provide subtle tactile feedback, allowing for precise blade manipulation.

While traditional, many modern Japanese knives also come with Western-style handles, blending the best of both worlds. This fusion aims to cater to a broader audience who might prefer the familiar feel of a riveted handle while still benefiting from Japanese blade craftsmanship.

The choice of handle significantly impacts the overall feel and balance of the knife, influencing how it performs during various cutting tasks and how comfortable it is for the user over extended periods of time. Exploring different knife handles can greatly enhance your culinary experience.

Weight Distribution and Fatigue: A Comparative Analysis

The differing handle designs and blade geometries lead to distinct weight distribution patterns in german knives vs japanese knives. German knives, with their full bolsters and thicker blades, tend to be heavier and have their balance point closer to the handle.

This heavier, handle-biased balance provides a feeling of stability and power, which is advantageous for tasks requiring force, such as chopping through dense ingredients. The momentum generated can assist in heavier cuts.

However, for extended periods of delicate, repetitive cutting, this weight can lead to greater hand and wrist fatigue. The user relies more on the knife’s inherent weight to assist in cutting, which requires less muscle engagement but more overall strain over time.

Japanese knives, with their lighter Wa-style handles and thinner blades, are often more blade-heavy or perfectly balanced at the pinch grip point. This lighter overall weight and forward balance allow for incredibly agile and precise movements.

This balance point reduces fatigue during intricate, repetitive tasks like fine dicing or slicing, as the chef uses less force and relies more on the knife’s sharpness and their own dexterity. It encourages a more nimble and fluid cutting style.

Ultimately, the preferred weight distribution and balance are subjective and depend on individual cutting style, hand size, and personal comfort. Understanding these nuances helps in selecting a knife that feels like a natural extension of your hand rather than just a tool.

Performance in Practice: Cutting Styles and Culinary Application

German Knives: Excelling in Rocking Chops and Heavy Prep Work

German knives, particularly the chef’s knife (kochteich), are designed to excel in the rocking chop motion. This technique involves keeping the tip of the blade on the cutting board while rocking the handle up and down to chop through ingredients.

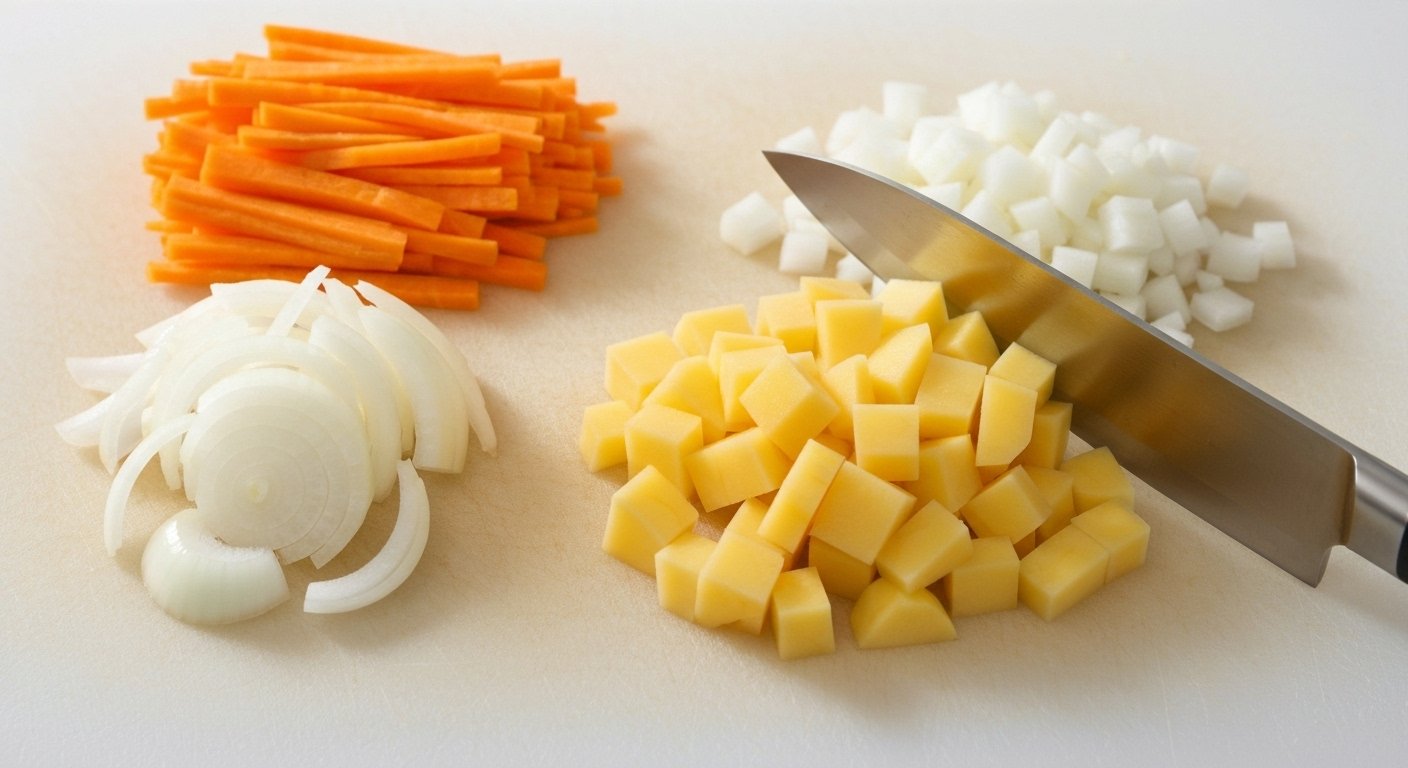

The pronounced curvature of the blade facilitates this motion, making quick work of dicing onions, mincing garlic, or chopping herbs. This cutting style is efficient for processing large quantities of ingredients.

Due to their robust construction, thicker blades, and tougher steel, German knives are the ideal choice for heavy-duty prep work. They handle tasks like breaking down large vegetables, sectioning poultry, or even light bone work with greater confidence.

Their durability means they are less susceptible to damage from accidental impacts or less-than-perfect cutting boards. They are forgiving tools, making them excellent for general kitchen use where versatility and resilience are paramount.

For home cooks who value a single, reliable knife that can handle almost anything thrown at it, a good German chef’s knife is often the go-to choice. It’s a dependable workhorse that rarely disappoints in general culinary applications.

Japanese Knives: Mastering Push Cuts and Delicate Slicing Tasks

Japanese knives, with their straight or flatter blade profiles and incredibly sharp edges, are designed for the push cut or pull cut technique. This involves drawing or pushing the knife straight through the ingredient, minimizing lateral movement.

This method allows for extremely clean, precise cuts with minimal bruising or tearing of delicate ingredients. It is essential for tasks where aesthetic presentation and textural integrity are crucial, such as slicing raw fish for sushi or creating fine julienne vegetables.

The thinness of Japanese blades reduces friction, allowing them to glide effortlessly through ingredients. This makes them ideal for intricate tasks that require finesse, such as filleting delicate fish, thinly slicing meats, or precise trimming.

While some Japanese knives, like the Santoku, incorporate a subtle belly for a slight rocking motion, their primary strength lies in their ability to perform exquisite push or pull cuts. They encourage a more deliberate and controlled cutting style.

For chefs specializing in specific cuisines, or home cooks who demand the utmost precision and aesthetic perfection in their culinary creations, a Japanese knife offers an unparalleled cutting experience.

Task-Specific Suitability: Butcher vs. Sushi Chef Preferences

The practical application of german knives vs japanese knives is vividly illustrated by their suitability for different culinary professions. A butcher, whose work involves breaking down large cuts of meat, often prefers the power and durability of German knives.

The robust blade of a German boning knife or cleaver can handle tough connective tissues and small bones without fear of chipping. Their ability to withstand heavy use makes them indispensable in high-volume, demanding environments.

A sushi chef, on the other hand, relies almost exclusively on Japanese knives, particularly single-bevel yanagiba and deba knives. The razor-sharp, thin edges are essential for creating immaculate, translucent slices of fish for sashimi and nigiri.

The precision afforded by these blades ensures minimal damage to delicate proteins, preserving their texture and flavor. For intricate knife work where perfection is key, Japanese knives are the undisputed masters.

For the home cook, the choice often comes down to personal cooking style and the types of dishes prepared most frequently. If you often chop hearty vegetables and meats, German knives might be more suitable. If you prioritize precision and delicate presentation, Japanese knives will shine.

Many professional kitchens and advanced home cooks often have a collection of both types, leveraging the strengths of each for specific tasks, creating a versatile arsenal of knives.

Longevity and Care: Durability, Maintenance, and Investment

Chipping vs. Rolling: Understanding Damage and Resilience

One of the most significant practical differences in maintenance between german knives vs japanese knives lies in how their edges react to stress. German knives, made from softer, tougher steel, tend to “roll” or bend when encountering hard surfaces or subjected to lateral force.

A rolled edge is not permanently damaged; the microscopic edge has simply bent over. This can often be corrected easily with a few passes on a honing rod, realigning the edge and restoring most of its cutting ability. This makes German knives more forgiving and resilient for everyday use.

Japanese knives, with their harder, more brittle steel and acute edge angles, are more prone to “chipping.” Instead of bending, small pieces of the blade edge can break off if the knife is dropped, twisted, or used on a very hard cutting surface (like glass or stone).

Chipping requires more extensive repair, usually involving regrinding the damaged section of the blade on a coarse whetstone. While repairable, it is a more involved process than simply honing a rolled edge and requires more skill and specialized tools.

Understanding these distinct damage patterns is crucial for proper care and handling, ensuring the longevity of your valuable kitchen tools. It reinforces the need for specific care routines for each knife type.

Cleaning and Storage: Preserving the Integrity of German and Japanese Blades

Proper cleaning and storage are paramount for extending the life of both German and Japanese knives, though the specific considerations differ. German knives, often made from highly corrosion-resistant stainless steel, are relatively low-maintenance.

While generally more forgiving, it is always recommended to hand wash German knives immediately after use with warm, soapy water and dry them thoroughly. Dishwashers can be harsh on knife handles and edges, even for durable German blades, leading to dulling and potential handle damage over time.

Japanese knives, particularly those made from high-carbon steel or with very high HRC ratings, require more meticulous care. They should be hand washed and dried immediately after every use, especially after cutting acidic foods, to prevent rust and discoloration.

Some traditional Japanese knives with reactive carbon steel blades will develop a patina over time, which is a desirable protective layer. However, this natural aging process still requires consistent cleaning to avoid harmful rust.

For storage, both types of knives benefit from being stored in a way that protects their edges and prevents them from knocking against other utensils. Options include magnetic knife strips, in-drawer knife blocks, or individual blade guards.

Avoiding the “knife drawer jumble” is critical for preserving the sharpness and integrity of any quality knife, but especially for the delicate edges of Japanese blades. Proper knife care and storage are investments in your tools’ longevity.

The Long-Term Value Proposition: Investment vs. Durability

When considering the investment in german knives vs japanese knives, it’s helpful to view it through the lens of long-term value. German knives are often seen as robust, reliable workhorses that offer excellent durability and a long lifespan with relatively low maintenance.

Their forgiving nature and ease of care make them a sound investment for general kitchen use, capable of enduring years of demanding daily tasks. While they might not offer the pinnacle of sharpness, their consistent performance and resilience provide significant value.

Japanese knives, while often requiring a higher initial investment and more diligent care, offer unparalleled cutting performance and a level of precision that can transform a chef’s capabilities. Their ability to hold a razor-sharp edge for extended periods can be a significant advantage in certain culinary applications.

For those who value extreme sharpness, delicate cuts, and a deeper connection to their tools, the meticulous care required for Japanese knives is a worthwhile trade-off. They represent an investment in a specialized tool designed for peak performance.

Ultimately, both German and Japanese knives, when properly cared for, can last a lifetime and be passed down through generations. The “better” investment depends entirely on the individual’s needs, culinary priorities, and willingness to engage in specific maintenance routines. It’s about aligning the tool with the user’s culinary journey.

Beyond Tradition: Hybrid Blades and Informed Selection

The Rise of Fusion: Blending German Strength with Japanese Precision

Recognizing the distinct advantages of both traditions, the culinary industry has seen the rise of “fusion” or hybrid knives that attempt to blend the best characteristics of german knives vs japanese knives. These knives often feature German-style ergonomics with Japanese-inspired blade geometry and steel.

For example, you might find a knife with a Western-style handle and a full tang, providing the familiar comfort and balance of a German knife, but with a thinner, harder blade made from Japanese steel (like VG-10 or AUS-10) with a more acute edge angle.

Brands like Shun (Kai Group), Global, and even some lines from Zwilling J.A. Henckels and Wüsthof now offer knives that bridge this gap. They aim to provide the best of both worlds: the durability and familiar feel of a German knife combined with the superior sharpness and edge retention of a Japanese blade.

These hybrid knives often feature a blade geometry that is thinner than traditional German blades but perhaps not as delicate as some single-bevel Japanese knives. They offer a versatile middle ground for those who appreciate both robustness and keen sharpness.

The innovation in knife manufacturing continues to evolve, catering to the diverse needs and preferences of modern chefs and home cooks. Fusion knives represent an exciting development, offering new possibilities for culinary tools.

Which Blade for You: Matching German and Japanese Knives to Your Needs

Deciding between german knives vs japanese knives often comes down to a clear understanding of your personal cooking style, priorities, and willingness to maintain your tools. There is no single “best” knife; only the best knife for *you*.

Consider a German knife if you prioritize durability, versatility, and ease of maintenance. If you’re a home cook who wants a reliable workhorse for everyday chopping, dicing, and general prep, and you prefer a more forgiving tool that can withstand heavy use, a German knife is an excellent choice.

Opt for a Japanese knife if you value extreme sharpness, precision, and aesthetic beauty. If you enjoy delicate tasks like preparing sushi, finely slicing proteins, or intricate vegetable cuts, and you are willing to invest time in meticulous care and whetstone sharpening, a Japanese blade will truly shine.

For those who find themselves in between, or who appreciate specific aspects of both, exploring hybrid knives might be the perfect solution. These offer a balance, combining the robustness of Western design with the cutting performance of Eastern metallurgy.

It’s also important to consider your budget and the types of ingredients you work with most frequently. A balanced approach, perhaps owning a few key knives of each type, can provide a versatile and comprehensive set for any culinary challenge.

Professional Insights: Chef Recommendations and Personal Preferences

Many professional chefs often have a curated collection of knives, utilizing both German and Japanese styles based on the task at hand. They understand that different culinary challenges require different tools, and a truly versatile chef leverages the strengths of each.

A chef might reach for a sturdy German chef’s knife for breaking down large quantities of vegetables during mise en place, valuing its durability and ability to handle a rocking chop. Later, they might switch to a nimble Japanese petty knife for delicate garnishes or a yanagiba for precise fish slicing.

Personal preference plays a huge role. Some chefs prefer the heft and balance of a German knife, finding its weight reassuring for consistent cuts. Others are drawn to the lightweight agility and unparalleled sharpness of Japanese blades, which they find less fatiguing for intricate work.

Ultimately, a chef’s recommendation often boils down to what feels right in their hand and what best supports their unique cooking philosophy and techniques. It’s a deeply personal connection between the artisan and their most vital tool.

The best way to make an informed decision is to handle various knives yourself. Visit specialty knife stores, feel the balance, and practice different grips to understand which knife truly resonates with your hand and cutting style. This hands-on experience is invaluable.

The Ultimate Edge: Deciphering the German vs. Japanese Knife Legacy

Synthesizing the Distinctions: A Recap for the Discerning Chef

The profound differences between german knives vs japanese knives are a testament to distinct culinary philosophies and historical craftsmanship. German knives epitomize durability, robustness, and versatility, built for the rigors of a busy kitchen and everyday use.

They feature thicker blades, full bolsters, softer steel (around 56-58 HRC), and wider edge angles (20-25 degrees per side). This design prioritizes toughness, ease of maintenance (honing rod friendly), and a powerful rocking chop cutting style.

Japanese knives, conversely, represent the pinnacle of precision, sharpness, and artistry. They boast exceptionally thin blades, harder steels (60-65+ HRC), and acute edge angles (10-15 degrees per side).

Their construction emphasizes razor-sharp edges, superior edge retention, and suitability for delicate push/pull cuts. While requiring more meticulous care (whetstone sharpening, careful handling), they deliver unparalleled performance for intricate tasks.

From the foundational artistry of their blade geometry to the metallurgical heart of their steel and the ergonomics of their handles, every aspect of these knives reflects a deliberate design choice. Their practical performance, maintenance requirements, and long-term value further highlight their unique positions in the culinary world.

Your Blade, Your Craft: Embracing the Best of Both Worlds

In the end, the debate of german knives vs japanese knives isn’t about one being inherently “better” than the other. It’s about understanding their specific strengths and weaknesses, and choosing the right tool for the right job, or for your preferred style of craftsmanship.

For many, the ideal kitchen arsenal includes a selection from both traditions. A robust German chef’s knife can handle the heavy-duty tasks, while a nimble Japanese gyuto or petty knife can be reserved for precision work and delicate ingredients.

This approach allows chefs and home cooks alike to leverage the strengths of each knife, optimizing their efficiency, precision, and enjoyment in the kitchen. It’s about building a collection that empowers your culinary creativity.

The journey into the world of knives is a continuous learning experience, rich with history, science, and art. Embracing the diverse legacies of German and Japanese knife making enriches your understanding of cooking tools and elevates your craft.

May your blades be sharp, your cuts precise, and your culinary adventures endless. Whether you choose the reliable workhorse or the delicate artisan’s tool, both German and Japanese knives offer an exceptional cutting experience that will serve your passion for food. 🔥

Explore More: Dive Deeper into the World of Knives

For more insights into the fascinating world of culinary blades, visit our blog at https://japaneseknivesworld.com/ where you can find a wealth of information. Discover more through these related articles: