Mastering the japanese knives sharpening angle is not merely a skill; it is an art form rooted in centuries of metallurgical tradition and cutting-edge craftsmanship. Achieving the optimal edge on a Japanese knife unlocks its full potential, transforming a simple blade into an unparalleled culinary instrument. This comprehensive guide delves into the intricate world of Japanese knife sharpening, offering insights crucial for both professional chefs and passionate home cooks alike.

The Precision Art of Japanese Knife Sharpening

Unpacking the Significance of Blade Geometry

Blade geometry is the fundamental blueprint of a knife, dictating how it interacts with the material it cuts. For Japanese knives, this geometry is particularly complex and purposeful. Each curve, taper, and bevel is meticulously designed to achieve specific cutting performance and durability characteristics.

Understanding the interplay between spine thickness, blade height, grind lines, and edge profile is paramount. These elements collectively determine the efficiency of the cut, the ease of food release, and the overall balance of the knife. Without a precise understanding of this geometry, true mastery of the japanese knives sharpening angle remains elusive.

The subtle nuances of blade geometry contribute significantly to the knife’s specialty. A yanagiba, designed for slicing fish, has a very different profile than a deba, intended for butchering. Recognizing these differences is the first step toward effective sharpening.

Why the Japanese Knives Sharpening Angle Demands Specific Mastery

The japanese knives sharpening angle is not a one-size-fits-all concept; it is a critical parameter that directly influences a knife’s performance, longevity, and versatility. Unlike many Western knives that often feature robust, blunt angles, Japanese blades are renowned for their incredibly thin, acute edges.

This sharpness is a direct result of the precise and often more acute angles employed during their creation and subsequent sharpening. A smaller angle means a finer edge, capable of slicing through delicate ingredients with minimal resistance and cellular damage. This precision is invaluable in Japanese cuisine, where presentation and texture are paramount.

Achieving and maintaining this specific angle requires patience, practice, and the right tools. It demands a level of sensitivity and control that differentiates true craftsmen from casual users. The mastery of this angle is what elevates a good knife to an extraordinary one.

The Distinct Philosophy Behind Japanese Knives Sharpening Angle

Historical Context of Japanese Blade Design and Edge Tradition

The tradition of Japanese blade design is deeply intertwined with the history of samurai swords. Centuries of meticulous craftsmanship, material science, and military application have refined the art of blade making. This heritage transitioned seamlessly into kitchen cutlery, bringing with it an unparalleled commitment to edge performance.

Early Japanese knives, much like their sword counterparts, were often single-beveled (kataba), optimized for specific cutting tasks and offering extreme sharpness. This focus on specialized tools for specialized tasks has always been a hallmark of Japanese craftsmanship.

The philosophy emphasizes harmony between the blade, the user, and the ingredient. Each knife is seen as an extension of the chef’s hand, and its edge, a reflection of their dedication. The historical emphasis on perfection laid the groundwork for the modern precision required for the japanese knives sharpening angle.

Key Differences: Japanese vs. Western Knife Angles and Their Purpose

One of the most significant distinctions between Japanese and Western knives lies in their typical sharpening angles. Western knives, like those from Wüsthof or Victorinox, commonly feature a total angle of 20-25 degrees (10-12.5 degrees per side). This wider angle provides robust durability, making them suitable for general-purpose kitchen tasks and less susceptible to chipping.

Conversely, many Japanese knives, particularly double-bevel (ryoba) types like a Gyuto, typically sport a much more acute total angle, often in the range of 10-15 degrees (5-7.5 degrees per side). Single-bevel knives, like a Yanagiba or Deba, are even more extreme, with a primary bevel on one side that can be as low as 10-15 degrees, with a subtle urasuki (concave grind) on the back. This acute japanese knives sharpening angle allows for incredibly precise cuts and minimal cell damage to food, preserving flavor and texture.

The purpose behind these differences stems from cultural culinary practices. Western cooking often involves more forceful chopping and general utility, while Japanese cuisine emphasizes delicate preparation, precise slicing, and aesthetic presentation. Each angle is optimized for its intended use, highlighting the thoughtful engineering behind both traditions.

The Micro-Edge: Understanding the Primary and Secondary Bevels

Many high-performance knives, especially those with more complex grinds, feature not just one, but often two distinct bevels that contribute to the final edge. The “primary bevel” is the main grind that forms the overall wedge shape of the blade, extending from the spine or middle of the blade down to just before the cutting edge.

The “secondary bevel” or “micro-bevel” is the final, very small angle ground right at the apex of the edge. This tiny bevel is what creates the ultimate sharpness. For some Japanese knives, particularly those designed for extreme sharpness and delicate work, this micro-bevel is incredibly fine and acute.

Understanding these multiple bevels is crucial when attempting to restore or refine the japanese knives sharpening angle. Sharpening often focuses on the secondary bevel, creating a hair-splitting edge, while thinning the primary bevel may be required periodically to maintain the overall blade geometry as it thickens behind the edge over time. This layered approach allows for a combination of strength and extreme sharpness.

Decoding Angles for Single-Bevel and Double-Bevel Japanese Knives

The Asymmetry of Kataba (Single-Bevel) Angles Explained

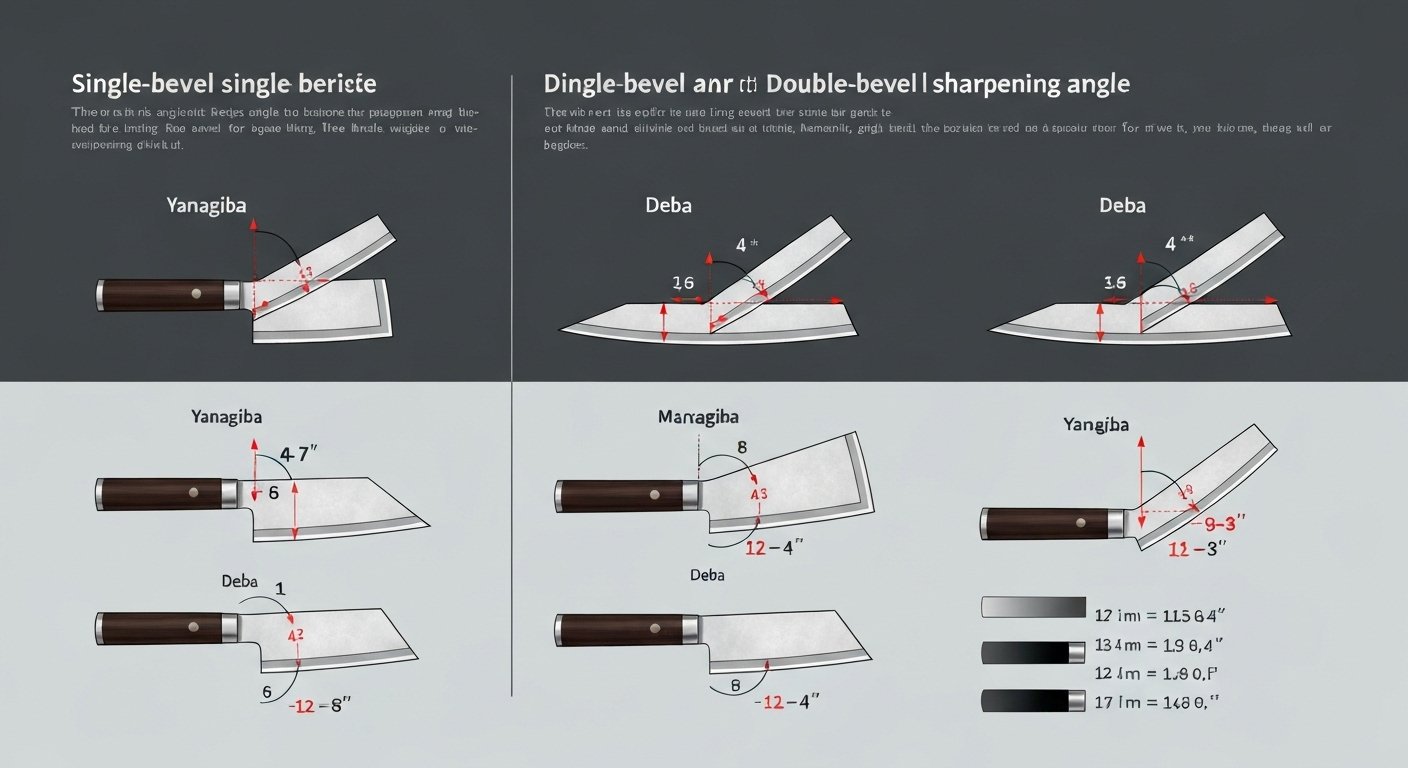

Single-bevel knives, known as kataba in Japanese, represent a pinnacle of specialized design. Examples include the Yanagiba (sushi slicer), Deba (fish butchering knife), and Usuba (vegetable knife). Their defining characteristic is an asymmetrical grind, where one side of the blade is entirely flat or slightly concave (urasuki), and the other side features the primary bevel and a very acute cutting edge.

The flat or concave side acts like a guide, allowing for incredibly precise, straight cuts without binding, especially important for tasks like slicing fish fillets. The bevelled side, meanwhile, pushes the sliced material away from the blade. This design, while offering unparalleled sharpness and precision for specific tasks, also makes these knives highly directional.

The sharpening of kataba knives is unique and demands a deep understanding of their geometry. The flat side is polished on a flat stone to maintain the urasuki, while the bevelled side receives the acute japanese knives sharpening angle, often between 10-15 degrees. Mastering this asymmetry is fundamental to properly maintaining these specialized tools.

For more details on maintaining these unique blades, explore our knife care section.

Symmetrical Precision: Ryoba (Double-Bevel) Japanese Knife Angles

Ryoba, or double-bevel knives, are the most common type of Japanese kitchen knife found in Western kitchens, including popular choices like Gyuto (chef’s knife), Santoku (all-purpose knife), and Petty (utility knife). Unlike single-bevel knives, ryoba blades feature a symmetrical grind, with bevels on both sides of the blade meeting in the middle to form the cutting edge.

While still more acute than most Western knives, the angles on ryoba blades are typically easier to sharpen for beginners, as they mimic the basic concept of sharpening two symmetrical sides. The total angle for a ryoba knife usually falls within the range of 10-15 degrees total, meaning 5-7.5 degrees per side.

This symmetrical design offers versatility, allowing for ambidextrous use and a broader range of cutting techniques. The precision in forming identical angles on both sides is crucial for maintaining the knife’s balance and cutting performance. Consistency in achieving the desired japanese knives sharpening angle on both facets ensures optimal edge alignment and keenness.

Specific Angle Ranges for Common Japanese Knife Types (e.g., Gyuto, Yanagiba, Deba)

Understanding the general angle ranges for different Japanese knife types is key to effective sharpening. While specific angles can vary based on manufacturer, steel type, and personal preference, these are good starting points:

- Gyuto (Chef’s Knife): Often sharpened to an angle of 10-15 degrees total (5-7.5 degrees per side). This provides a good balance of sharpness for general cutting tasks while maintaining reasonable durability.

- Santoku (All-Purpose Knife): Similar to Gyuto, a total angle of 10-15 degrees is common, offering versatility for slicing, dicing, and chopping.

- Petty (Utility Knife): Given its smaller size and precision tasks, a slightly more acute angle, perhaps 8-12 degrees total (4-6 degrees per side), can be effective for delicate work.

- Yanagiba (Slicer – Single Bevel): This knife is typically sharpened on one side to a very acute angle, often between 10-15 degrees for the primary bevel, with the back (urasuki) flattened or slightly concave. The extreme sharpness allows for clean, long slices without tearing.

- Deba (Fish Butcher – Single Bevel): Designed for heavy-duty work, a Deba’s main bevel is usually around 15-20 degrees, making it more robust than a Yanagiba, while still being very sharp. The urasuki on the back is also critical.

- Usuba (Vegetable Knife – Single Bevel): For fine vegetable work, a typical angle for the primary bevel is 10-15 degrees, allowing for incredibly thin slicing and intricate cuts.

Adhering to these angle ranges is vital for preserving the intended performance and longevity of each specific knife type. Experimentation within these ranges, coupled with consistent practice, will help you find the perfect japanese knives sharpening angle for your needs. For more specific angles based on different steel types, refer to our comprehensive sharpening techniques guide.

Achieving and Maintaining the Optimal Japanese Knives Sharpening Angle

Ergonomics and Hand Placement for Consistent Angle During Sharpening

Consistency is the cornerstone of effective sharpening. Achieving a consistent japanese knives sharpening angle throughout the sharpening process requires meticulous attention to ergonomics and hand placement. The goal is to create a stable, repeatable platform for the blade as it moves across the sharpening stone.

Proper posture is crucial; stand upright with your body aligned with the stone. Place your non-dominant hand on the blade, fingers spread to apply even pressure across the edge, while your dominant hand controls the handle. The key is to lock your wrists and elbows, moving your entire arm and shoulder as one unit to maintain a steady angle.

Visualize the angle. Many sharpeners use the “fingertip test” to feel the burr, which confirms the angle is being met. Others might employ a sharpie trick, coloring the edge and observing where the marker is removed by the stone. Consistent pressure, coupled with a smooth, controlled stroke, is paramount to achieving the desired angle without rocking the blade.

Advanced Techniques for Angle Verification and Adjustment on the Fly

While intuition plays a significant role in freehand sharpening, several advanced techniques can help verify and adjust the japanese knives sharpening angle with precision. The “burr test” is fundamental: a successful sharpening pass on one side will raise a microscopic burr (a wire edge) on the opposite side. Feeling this burr uniformly along the entire edge confirms you’re hitting the apex consistently.

Another technique involves using a sharpie marker. Color the entire bevel of the knife edge. As you make a few passes on the stone, observe where the marker is being removed. If it’s removed only at the very edge or very heel, your angle is too low or too high, respectively. The goal is for the marker to be removed evenly across the entire bevel, indicating you’re maintaining the correct angle.

For fine-tuning, micro-beveling can be employed. After achieving the primary edge, slightly increase the angle for a few light strokes on a very fine grit stone. This creates a tiny, stronger secondary bevel that can enhance edge retention without sacrificing much sharpness. Practice with these methods on less valuable knives first to hone your technique.

Common Pitfalls in Angle Maintenance and Their Expert Solutions

Maintaining a consistent japanese knives sharpening angle can be challenging, and several common pitfalls can hinder progress. One frequent issue is inconsistent pressure, leading to uneven sharpening and a wavy edge. Solution: Focus on even pressure distributed along the blade and throughout the stroke. Use your non-dominant hand to guide the blade and apply pressure consistently.

Another pitfall is rocking the blade during the stroke, which rounds off the edge instead of creating a sharp apex. Solution: Keep wrists and elbows locked, moving your entire arm as a single unit. Practice slow, deliberate strokes until muscle memory develops. Angle guides, while not for mastery, can help beginners understand the feel of a consistent angle.

Over-sharpening one section of the blade (e.g., the belly or tip) while neglecting others is also common. Solution: Divide the blade into imaginary sections and ensure each section receives equal attention and strokes. Rotate the knife to ensure the entire edge is sharpened uniformly. Regularly check for a burr along the entire length of the blade to confirm even sharpening.

Finally, not maintaining the correct water level on a whetstone can impact sharpening. Solution: Always keep whetstones adequately saturated, as a dry stone can lead to inconsistent friction and heat buildup. Consistency in all these elements is key to mastering the japanese knives sharpening angle.

The Influence of Steel Composition and Blade Profile on Sharpening Angles

Adapting Angles for Different Japanese Knife Steels (e.g., Carbon vs. Stainless)

The type of steel used in a Japanese knife significantly influences the ideal japanese knives sharpening angle and the sharpening process itself. Japanese knives are broadly categorized by their steel type: carbon steel and stainless steel.

Carbon steel knives, such as those made from Aogami (Blue Steel) or Shirogami (White Steel), are known for their exceptional sharpness and ease of sharpening. They can typically hold a very acute angle, often as low as 8-12 degrees per side, due to their fine grain structure and high hardness. However, they are prone to rust and reactivity. When sharpening carbon steel, one can often push for a slightly finer angle to maximize initial sharpness, as the steel’s inherent toughness allows it to hold this acute edge well.

Stainless steel knives, while more resistant to corrosion, often contain chromium and other alloying elements that make them tougher and sometimes harder to sharpen to an extreme edge. Steels like VG-10, AUS-8, or SG2 (R2) are common. While they can still achieve impressive sharpness, aiming for a slightly less acute angle (e.g., 10-15 degrees per side) might be more practical for long-term edge retention and chip resistance, given their composition. They might also require more time on finer grit stones to achieve a polished edge. Understanding these material properties helps in choosing the correct japanese knives sharpening angle and technique.

Edge Retention vs. Ultimate Sharpness: The Angle Trade-off

There is a fundamental trade-off when determining the japanese knives sharpening angle: edge retention versus ultimate sharpness. A more acute (smaller) angle creates a thinner, sharper edge that can slice through ingredients with incredible ease, minimizing resistance and maximizing precision. This is the hallmark of many traditional Japanese knives.

However, an extremely acute angle also means less material supporting the very apex of the edge. This can make the edge more prone to damage, such as rolling, chipping, or dulling quickly, especially with heavier use or contact with harder surfaces. It sacrifices some durability for peak cutting performance.

Conversely, a slightly wider (larger) angle creates a more robust, durable edge with better edge retention. While not as “razor-sharp” initially, it will withstand more abuse and maintain a working edge for a longer period before requiring resharpening. Professional kitchens often balance these factors, sometimes opting for a slightly less acute angle for daily workhorses to reduce maintenance frequency.

The ideal angle is a balance point, depending on the knife’s steel, intended use, and the user’s sharpening frequency and skill. An expert sharpener understands this trade-off and can customize the japanese knives sharpening angle to suit specific needs, prioritizing either peak performance or extended durability.

Micro-Bevels and Convex Grinds: Enhancing the Japanese Knives Sharpening Angle

Beyond the primary and secondary bevels, advanced sharpening techniques like incorporating micro-bevels or understanding convex grinds can significantly enhance the performance of a Japanese knife. A micro-bevel is a very small, slightly steeper angle applied at the very apex of the edge on the final finishing stone. It acts as a reinforcement, strengthening the otherwise fragile, acute edge without significantly compromising overall sharpness.

For example, a blade sharpened to a 10-degree per side angle might have a micro-bevel of 12-15 degrees for the last few strokes. This technique improves edge retention and resistance to chipping, making the japanese knives sharpening angle more resilient for daily use. It’s particularly useful for professional chefs who need their knives to perform under demanding conditions.

Convex grinds, sometimes found on traditional Japanese knives like some Debas, present a different challenge. Instead of flat bevels, the blade tapers to the edge with a gentle curve. This geometry provides incredible strength behind the edge while still allowing for a very acute cutting angle. Sharpening convex grinds requires careful technique to maintain the curved profile, often involving softer stones, leather strops, or specialized equipment to roll the edge and preserve the convex shape. Understanding these nuances allows for a deeper mastery of the japanese knives sharpening angle.

Performance Implications of the Perfect Japanese Knives Sharpening Angle

How Angle Directly Affects Cutting Dynamics and Food Release

The japanese knives sharpening angle is not just about how sharp a knife feels; it fundamentally alters the entire cutting dynamic and influences how easily food releases from the blade. A perfectly sharpened, acute angle creates a very thin wedge that encounters minimal resistance as it passes through food. This results in incredibly clean, effortless cuts, reducing the physical strain on the user.

When slicing delicate ingredients like fish or soft vegetables, a sharp, acute angle minimizes cellular damage, preserving the integrity of the food. This translates to better flavor, texture, and presentation, which are critical in Japanese cuisine. The knife essentially glides through the material rather than tearing or crushing it.

Furthermore, the blade’s geometry, which is heavily influenced by the sharpening angle, impacts food release. A thinner, more acute edge coupled with a proper blade taper (like a kireba or hira-zukuri grind) reduces the surface area contact between the blade and the food, making it less likely for ingredients to stick. This ensures a smoother, more efficient workflow in the kitchen, a direct benefit of perfecting the japanese knives sharpening angle.

The Longevity Factor: Angle’s Role in Edge Durability and Chip Resistance

While an acute japanese knives sharpening angle delivers superior initial sharpness, its precise execution is critical for the knife’s longevity and chip resistance. An angle that is too acute for the steel type or intended use can lead to premature dulling, rolling of the edge, or even micro-chipping, especially on harder materials or during lateral forces. This means constant resharpening and potential edge degradation over time.

Conversely, a slightly wider angle, while not offering the absolute keenest edge, provides more material behind the apex, making the edge more robust and resistant to damage. This increased durability extends the time between sharpenings and reduces the risk of serious edge deformation. For high-performance steels that are inherently more brittle, finding this balance is paramount.

Proper angle maintenance also involves thinning the blade over time. As a knife is sharpened repeatedly, the blade thickens behind the edge. If this isn’t addressed, the effective cutting angle increases, leading to wedging and poor performance despite a sharp apex. Periodically thinning the primary bevel restores the original blade geometry, ensuring the japanese knives sharpening angle remains effective and durable throughout the knife’s lifespan, contributing significantly to its overall longevity. This holistic approach ensures your investment lasts for decades.

Recognizing and Correcting Issues from Improperly Sharpened Angles

Identifying problems stemming from an improperly sharpened japanese knives sharpening angle is crucial for correction and improvement. One common issue is a “rounded” edge, where the angle isn’t consistently held, leading to a dull edge despite sharpening efforts. This can be identified by the knife feeling less precise and “skating” over soft vegetables rather than biting into them. The solution involves re-establishing a consistent angle from heel to tip, focusing on stable hand placement and arm movement.

Another problem is micro-chips or rolls, often indicating an angle that is too acute for the steel or the cutting task, or perhaps excessive pressure during sharpening. Chips appear as tiny nicks, while rolls manifest as bright, shiny spots along the edge. Correcting this requires either slightly increasing the sharpening angle to strengthen the edge or using a coarser stone to remove the damaged material and then re-establishing the proper japanese knives sharpening angle.

A “burr” that is not uniform or does not form at all suggests inconsistent angle application or insufficient sharpening. This leads to a knife that feels sharp in some spots but dull in others. The fix is to ensure the entire edge meets the stone at the correct angle, applying even pressure, and observing for a consistent burr. Persistent practice and self-correction are key to overcoming these issues and achieving a truly sharp and resilient edge. Consistent effort will pay dividends in the long run.

Debunking 7 Common Myths About Japanese Knives Sharpening Angle

Myth 1: One Angle Fits All Japanese Knives

Perhaps the most pervasive myth surrounding the japanese knives sharpening angle is the belief that a single, universal angle applies to all Japanese knives. This is fundamentally untrue and detrimental to knife performance. As discussed, Japanese knives are highly specialized tools, each designed for specific tasks and often made from different steels and with varying geometries.

A yanagiba, with its single bevel and acute edge for slicing fish, requires a vastly different sharpening approach and angle than a robust deba, designed for breaking down fish bones. Similarly, a ryoba Gyuto, intended as a general-purpose chef’s knife, will perform optimally at an angle that balances sharpness and durability, which may differ from a delicate Petty knife used for intricate work.

Attempting to apply a single japanese knives sharpening angle to every knife in your collection will inevitably lead to suboptimal performance, premature dulling, or even damage. True mastery lies in understanding the unique requirements of each blade and adapting your sharpening technique accordingly. Each knife is a unique entity with distinct needs.

Myth 2: Sharper Angles Always Mean Better Performance

While an acute japanese knives sharpening angle certainly contributes to initial sharpness and ease of cutting, the myth that “sharper angles always mean better performance” is a dangerous oversimplification. Pushing for the absolute thinnest, most acute angle possible without considering the knife’s steel, intended use, or the user’s skill level can lead to detrimental outcomes.

An excessively acute angle, particularly on certain steel types or for knives subjected to demanding tasks (like breaking down poultry or cutting through hard vegetables), can result in a fragile edge. This fragile edge is prone to chipping, rolling, or rapid dulling, ironically leading to worse performance and more frequent, intensive resharpening.

The optimal angle is a balance point between keenness and durability. For a professional chef who uses their knife rigorously for hours, a slightly less acute but more robust japanese knives sharpening angle might provide better overall performance and edge retention throughout a demanding shift. Ultimate sharpness is only “better” if it’s sustainable and functional for the intended application. This balance is critical.

Myth 3: Angle Guides are Always Necessary for Japanese Knife Sharpening

The myth that angle guides are always necessary for sharpening Japanese knives is perpetuated by those who might be intimidated by freehand sharpening. While angle guides can be useful tools for beginners to establish a baseline feel for a specific japanese knives sharpening angle, they are by no means a prerequisite for effective Japanese knife sharpening, nor are they a substitute for developing freehand skills.

Many traditional Japanese craftsmen and master sharpeners exclusively use freehand techniques, relying on muscle memory, tactile feedback, and visual cues. Freehand sharpening allows for greater adaptability, enabling the sharpener to adjust angles on the fly, work around subtle blade curves, or address specific damage spots with precision that fixed-angle guides cannot offer.

Moreover, angle guides typically apply a uniform angle, which may not be ideal for the entire length of a blade (e.g., slight variations might be desired at the tip or heel) or for single-bevel knives. While they can aid in learning, aspiring sharpeners should eventually strive to develop the freehand skill to truly master the japanese knives sharpening angle. They are a crutch, not a solution for long-term mastery.

The Future of Japanese Knives Sharpening Angle: Innovation and Craft

Emerging Technologies and Tools for Precision Sharpening

The world of knife sharpening is constantly evolving, with new technologies and tools emerging to aid in achieving and maintaining the precise japanese knives sharpening angle. While traditional whetstones remain the gold standard for many, innovations are making precision sharpening more accessible and consistent.

Controlled angle sharpening systems, such as those from Edge Pro or Wicked Edge, offer highly repeatable angles using abrasive stones or diamonds. These systems provide a stable platform and precise angle settings, making it easier for users to achieve consistent results, particularly for double-bevel knives. While they differ from traditional freehand methods, they allow for extreme precision.

Digital angle finders, laser-guided sharpeners, and even sophisticated computer-numerical-controlled (CNC) grinding machines are also finding their way into advanced workshops and professional sharpening services. These technologies promise unparalleled accuracy and consistency in setting the japanese knives sharpening angle, pushing the boundaries of what’s possible. However, the artistry of traditional methods still holds a special place, complementing these innovations.

The Enduring Value of Traditional Freehand Sharpening Techniques

Despite advancements in technology, the enduring value of traditional freehand sharpening techniques for the japanese knives sharpening angle remains undisputed. Freehand sharpening on whetstones is not just a method; it’s a meditative practice that connects the user intimately with their blade.

This method offers unparalleled control and adaptability. A skilled freehand sharpener can intuitively adjust pressure, angle, and stroke based on the knife’s unique geometry, the steel’s properties, and the desired edge. They can feel the burr forming, listen to the feedback from the stone, and visually assess the progress, making micro-adjustments that fixed-angle systems cannot replicate.

Traditional techniques foster a deep understanding of the blade’s characteristics and the physics of sharpening. It builds muscle memory, patience, and a nuanced appreciation for the art of the edge. For many enthusiasts and professionals, mastering the japanese knives sharpening angle freehand is a rite of passage, a testament to dedication and skill that machine-aided sharpening simply cannot replicate. It’s an art form passed down through generations.

Continuous Learning and Adaptation in Blade Maintenance

The journey to mastering the japanese knives sharpening angle is one of continuous learning and adaptation. Knife maintenance is not a static skill; it evolves with new blade designs, steel compositions, and sharpening tools. Staying updated with the latest research and techniques is crucial for anyone serious about knife care.

Engaging with the sharpening community, whether through online forums, workshops, or professional courses, provides invaluable opportunities for growth. Learning from experienced sharpeners, sharing insights, and experimenting with different methods can accelerate your progress and deepen your understanding. Embrace curiosity and an open mind.

Moreover, adapting your sharpening approach to the specific needs of each knife and its user is a hallmark of an expert sharpener. This includes knowing when to thin a blade, how to repair chips, or when to adjust the japanese knives sharpening angle for a different cutting task. The pursuit of sharpening perfection is a lifelong endeavor, rewarding those who commit to its continuous refinement. It’s a journey, not a destination, for true enthusiasts.

The Enduring Pursuit of Sharpening Perfection

Synthesizing the Expertise on Japanese Knives Sharpening Angle

Synthesizing the vast expertise surrounding the japanese knives sharpening angle reveals a complex yet profoundly rewarding discipline. It’s clear that this isn’t a simple mechanical task but an intricate blend of historical tradition, material science, precise technique, and artistic intuition. We’ve explored how blade geometry dictates performance, how single-bevel and double-bevel knives demand distinct approaches, and the critical role of ergonomics and consistent hand placement.

Understanding the nuances of different steel types and their influence on ideal angles is paramount. The delicate balance between ultimate sharpness and durable edge retention highlights the need for thoughtful adaptation rather than rigid adherence to a single numerical value. Moreover, recognizing common sharpening pitfalls and applying expert solutions transforms frustration into progress.

From debunking common myths to embracing emerging technologies while valuing traditional freehand skills, every aspect contributes to the holistic mastery of the japanese knives sharpening angle. This comprehensive understanding empowers both novice and seasoned sharpeners to elevate their blades to their peak potential, unlocking a superior culinary experience with every cut.

The Continuous Journey of Edge Mastery: A Final Reflection

The journey of edge mastery, particularly with the japanese knives sharpening angle, is truly a continuous one. It’s a path marked by persistent practice, keen observation, and an unwavering commitment to improvement. Each time you put a knife to stone, you’re not just sharpening a blade; you’re honing your skills, deepening your understanding, and refining your connection to an ancient craft.

Embrace the challenges, learn from every mistake, and celebrate every successful burr. The satisfaction of feeling a perfectly sharpened edge glide effortlessly through food is unparalleled, a testament to your dedication. This pursuit of sharpening perfection is more than just maintaining a tool; it’s a meditative art form that yields profound benefits in the kitchen and beyond.

May your blades always be keen, and your sharpening journey be ever-rewarding. The pursuit of the ideal japanese knives sharpening angle is a lifelong passion that continually inspires and delights. Keep learning, keep practicing, and enjoy the transformative power of a truly sharp knife.

Explore more about Japanese knives and sharpening techniques on our blog: https://japaneseknivesworld.com/