The culinary world reveres precision, artistry, and heritage, qualities epitomized by the

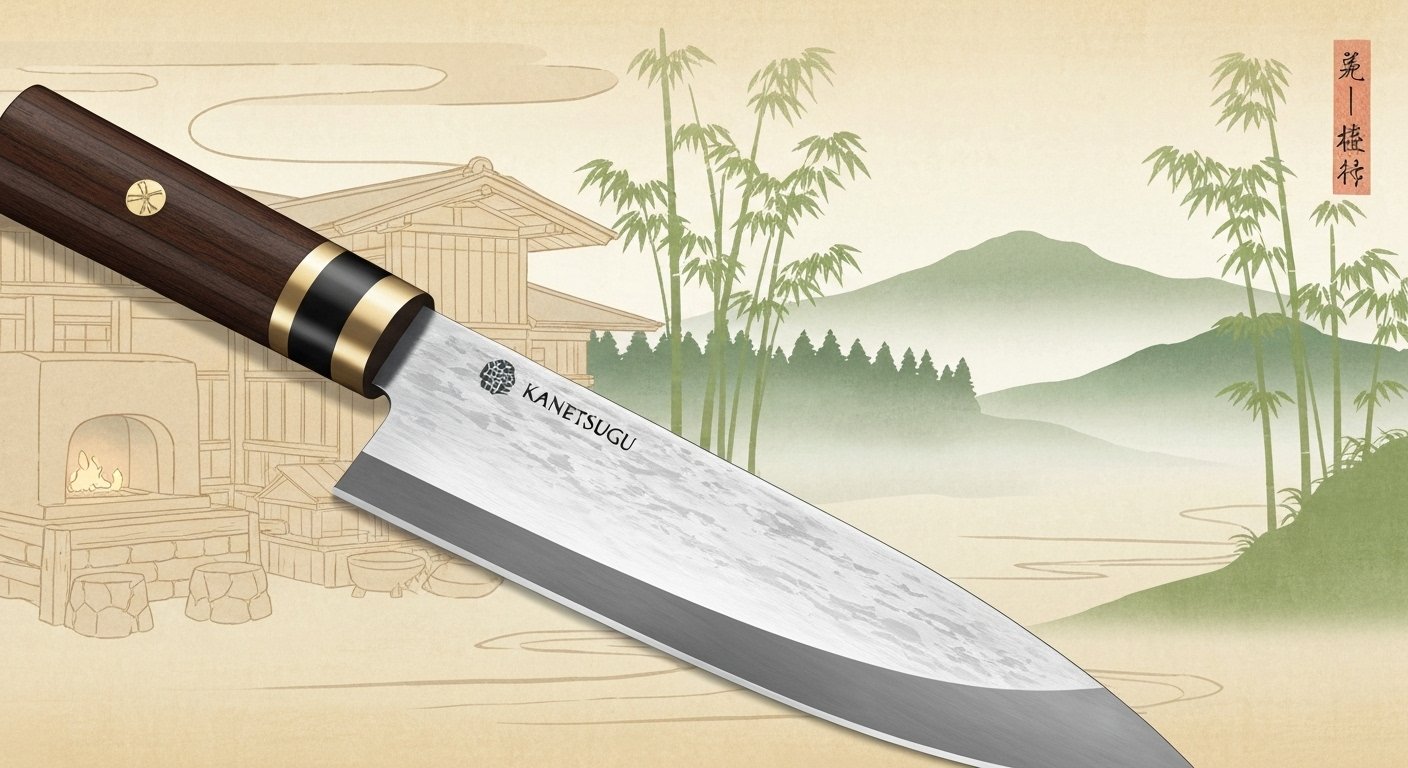

The culinary world reveres precision, artistry, and heritage, qualities epitomized by the kanetsugu knife. For discerning chefs and home cooks alike, this Japanese blade represents a pinnacle of craftsmanship, seamlessly blending traditional techniques with cutting-edge innovation. Discovering the excellence of a kanetsugu knife means understanding its deep roots, superior materials, and the meticulous attention to detail that defines every piece.

From its origins in Seki City, a historical hub for Japanese sword making, the kanetsugu knife has evolved, maintaining its core philosophy of creating tools that elevate the culinary experience. Its reputation is not merely built on sharp edges but on a holistic approach to knife design that considers balance, ergonomics, and long-term performance. This comprehensive guide will delve into what makes a kanetsugu knife a preferred instrument for professionals worldwide.

The Legacy of Precision: Exploring the Kanetsugu Knife

A Heritage Forged in Seki, Japan

Seki City, located in Gifu Prefecture, has been the heartland of Japanese blade forging for over 700 years. This rich history began in the Kamakura period (1185-1333), when master swordsmith Motoshige moved to Seki, drawn by the abundant natural resources like high-quality iron sand, charcoal, and pristine water. His pioneering spirit laid the groundwork for a tradition of blade making that continues to thrive today, making Seki a global center for knife production, and specifically, for the development of the kanetsugu knife.

The techniques perfected by ancient swordsmiths, such as differential hardening and multi-layered steel construction, were meticulously passed down through generations. These foundational methods form the bedrock of modern Japanese knife making, distinguishing Seki-made blades from their counterparts around the world. Kanetsugu, as a brand, emerged from this illustrious lineage, inheriting centuries of accumulated knowledge and unparalleled skill. Their artisans are not just manufacturers; they are custodians of a profound cultural legacy, ensuring that the spirit of the samurai sword lives on in every Japanese chef knife they create.

This deep respect for tradition is evident in the forging process, where attention to detail is paramount, from selecting the finest raw materials to the final honing of the edge. The dedication to preserving these ancestral methods, while simultaneously embracing modern metallurgical advancements, is what sets the kanetsugu knife apart. Each knife is a testament to Seki’s enduring reputation as a beacon of blade craftsmanship, embodying a blend of historical reverence and contemporary innovation that few other regions can match.

The unique environment of Seki, with its natural resources and skilled labor force, created a perfect storm for the development of high-performance blades. This geographical and historical advantage allowed Kanetsugu to refine its techniques over decades, producing a kanetsugu knife that is not just a tool, but a piece of functional art. The city’s water, in particular, played a crucial role in the quenching process, contributing to the unique properties and durability of the steel. This intricate connection between the land, the people, and the craft continues to define the quality and character of every blade produced in Seki.

Moreover, Seki’s history fostered a culture of continuous improvement and meticulous standards. Swordsmiths were revered figures, and their reputation rested on the unparalleled quality and performance of their creations. This ethos of perfection permeated the entire industry, establishing benchmarks for sharpness, durability, and aesthetic appeal. The kanetsugu knife stands as a direct descendant of this demanding tradition, benefiting from generations of artisans who strived for nothing less than excellence in every single blade.

The city also became a hub for innovation, as blacksmiths and artisans constantly experimented with new techniques and materials to enhance blade performance. This dynamic environment encouraged collaboration and knowledge sharing, further solidifying Seki’s position as a leader in blade technology. The legacy is not just about old techniques but about an adaptive and innovative spirit that has been passed down, ensuring the types of Japanese knives produced here, including the kanetsugu knife, remain at the forefront of culinary tools globally.

This rich heritage forms the very soul of the kanetsugu knife. It’s a heritage that speaks of resilience, artistic endeavor, and an unwavering commitment to mastery. The reputation of Seki as a world-class center for blade manufacturing is inextricably linked to brands like Kanetsugu, which uphold and extend its storied past into the future. Choosing a kanetsugu knife is, in essence, choosing a piece of this profound history, a blade forged with centuries of expertise and a passion for perfection.

Why the Kanetsugu Knife Commands Respect in Culinary Arts

In the demanding environment of professional kitchens, where speed, precision, and endurance are paramount, the kanetsugu knife has earned its place as an indispensable tool. Its reputation is built on a foundation of exceptional sharpness, superior edge retention, and remarkable balance, qualities that directly translate into improved efficiency and reduced fatigue for chefs. The ability of a kanetsugu knife to maintain its razor-sharp edge through prolonged use is a critical advantage, minimizing downtime for sharpening during busy service periods.

Beyond its cutting performance, the design philosophy behind every kanetsugu knife prioritizes user comfort and control. The ergonomic handles are meticulously crafted to fit snugly in the hand, allowing for a comfortable grip even during extended periods of intricate work. This thoughtful design minimizes strain on the wrist and hand, a crucial factor for chefs who spend countless hours preparing ingredients. The superb balance of a kanetsugu knife, often achieved through precise weight distribution between the blade and handle, enhances maneuverability and allows for fluid, controlled movements, reducing the likelihood of accidents.

The aesthetic appeal of a kanetsugu knife also contributes to its high regard. Many models feature stunning Damascus patterns, a result of layering different types of steel, which not only provides structural integrity but also creates a beautiful visual texture. This blend of form and function elevates the kanetsugu knife from a mere tool to a work of art, inspiring confidence and pride in its user. Chefs often view their knives as an extension of themselves, and a beautifully crafted kanetsugu knife becomes a symbol of their dedication to their craft.

Furthermore, the consistent quality control upheld by Kanetsugu ensures that every kanetsugu knife leaving their workshop meets the highest standards. This reliability is vital for professionals who depend on their tools to perform flawlessly day in and day out. The brand’s commitment to excellence has fostered a strong trust within the culinary community, making a kanetsugu knife a trusted companion for everything from delicate slicing of sashimi to robust chopping of vegetables. This unwavering consistency is a testament to the rigorous standards maintained throughout the entire manufacturing process.

The versatility of the kanetsugu knife range also contributes to its widespread adoption in professional settings. Whether a chef requires the precise tip of a Gyuto knife for general-purpose tasks, the broad blade of a Santoku knife for versatile chopping, or a specialized sushi knife for intricate fish preparation, Kanetsugu offers a solution. This comprehensive selection allows chefs to build a collection of tools tailored to their specific needs, all while benefiting from the superior quality synonymous with the kanetsugu knife name.

Finally, the durability and longevity of a kanetsugu knife represent a significant investment for professionals. Designed to withstand the rigors of daily kitchen use, these knives are not merely ephemeral tools but lasting companions that can serve a chef for decades with proper care. This enduring performance makes the initial investment in a kanetsugu knife a wise decision, as it reduces the need for frequent replacements and ensures consistent quality of work over time. The combination of artistry, performance, and longevity truly solidifies the kanetsugu knife‘s esteemed position in the world of culinary arts, earning it the deep respect it commands.

The Artisan’s Journey: Kanetsugu’s Storied Past

Roots in Seki: Birthplace of the Japanese Blade

The history of Kanetsugu is inextricably linked to Seki City, a place synonymous with the finest Japanese blades. The region’s natural abundance – rich iron sand, high-quality charcoal, and plentiful clean water from the Nagara River – provided the ideal conditions for sword-making to flourish from the 13th century onwards. It was here that master swordsmiths perfected techniques that blended strength with unparalleled sharpness, establishing Seki as the undisputed capital of blade craftsmanship in Japan. The very essence of what defines a high-quality kanetsugu knife originates from this crucible of innovation and tradition.

During the Sengoku period (1467-1615), a time of constant warfare, Seki’s swordsmiths were in high demand, producing thousands of swords for samurai warriors. This intense period of production led to rapid advancements in metallurgy and forging techniques, laying the foundation for the precision and durability that would become hallmarks of Seki-made blades. The spirit of these ancient warriors and their demand for exceptional weapons permeates the very DNA of every kanetsugu knife crafted today. The relentless pursuit of a superior edge and robust construction remains a core tenet.

Even after the decline of the samurai era, Seki’s blade-making tradition pivoted, adapting its advanced techniques to produce civilian cutlery, including kitchen knives. This transition was seamless, as the skills required for crafting a formidable sword translated perfectly to creating a razor-sharp kitchen tool. Kanetsugu, founded in 1918 by Katsujiro Kawamura, consciously drew upon this profound heritage, aiming to apply the same exacting standards of sword-making to the production of kitchen knives. Kawamura envisioned a kanetsugu knife that would bring the legacy of samurai precision to the everyday kitchen.

The unique geological features of Seki, particularly the pristine water, played a crucial role in the heat treatment process, imparting distinct characteristics to the steel. The water’s purity and mineral content influenced the quenching process, contributing to the exceptional hardness and toughness found in a kanetsugu knife. This symbiotic relationship between the natural environment and human ingenuity fostered a unique blade-making culture that has been meticulously preserved and passed down through generations of artisans at Kanetsugu.

Moreover, Seki’s historical prominence as a blade-making center meant that a highly skilled workforce, proficient in all aspects of knife production, was readily available. This concentration of expertise fostered an environment of continuous learning and refinement, where master craftsmen mentored apprentices, ensuring that intricate techniques were faithfully transmitted. The enduring commitment to traditional methods, coupled with an openness to modern advancements, allowed the kanetsugu knife to evolve while staying true to its Seki roots. This blend of old and new is a defining characteristic of their exceptional blades.

The city also established rigorous quality control standards, becoming known for its meticulous attention to detail at every stage of production. This reputation for unwavering quality has attracted discerning buyers from around the globe, further cementing Seki’s status as a leader in knife manufacturing. When you hold a kanetsugu knife, you are not just holding a tool; you are holding a piece of this extraordinary heritage, a blade forged in a place where centuries of craftsmanship converge to create excellence. This deep historical connection provides a sense of authenticity and trust, making the kanetsugu knife highly sought after.

The artisans at Kanetsugu are not just employees; they are part of a lineage, dedicated to honoring the legacy of their predecessors while pushing the boundaries of what a kitchen knife can achieve. Their work embodies the spirit of Seki: a relentless pursuit of perfection, a deep respect for materials, and an unwavering commitment to the user. This profound connection to its origins ensures that every kanetsugu knife continues to embody the very best of Japanese blade-making traditions, making it a true masterpiece of culinary engineering.

Evolution of Kanetsugu Knife Craftsmanship Through Eras

The journey of Kanetsugu knife craftsmanship mirrors the broader evolution of Japanese metallurgy and design, adapting to new technologies while steadfastly preserving core traditions. Founded in 1918 by Katsujiro Kawamura, the company initially focused on a wide range of cutting tools, gradually specializing in kitchen knives as demand grew. The early kanetsugu knife models were often simpler, reflecting the available steels and forging techniques of the early 20th century, yet they already demonstrated a commitment to sharpness and durability.

In the post-World War II era, as Japan rebuilt and industrialized, Kanetsugu embraced advancements in steel production and manufacturing processes. The introduction of stainless steels like AUS-8 and later VG-10 revolutionized kitchen knife production, offering improved corrosion resistance and ease of maintenance, making the kanetsugu knife more accessible to a wider market. This period saw a shift towards mass production methods, but Kanetsugu maintained its artisan touch, ensuring that quality was never compromised for quantity. The balance between traditional hand finishing and modern machinery became a hallmark.

The 1980s and 1990s marked a significant period of innovation for Kanetsugu. The company began experimenting with more exotic and high-performance steels, notably pioneering the use of ZDP-189, a super steel known for its exceptional hardness and edge retention. This bold move positioned the kanetsugu knife at the forefront of the premium knife market, appealing to professional chefs and enthusiasts seeking ultimate performance. The development of their proprietary “Hamaguri-ba” or clam-shaped edge, a convex grind, further differentiated their blades, enhancing cutting performance and durability.

In the 21st century, the evolution of the kanetsugu knife has focused on refining existing lines, introducing new ergonomic designs, and exploring advanced material composites for handles. They have consistently sought to optimize the balance between blade geometry, steel type, and handle comfort, ensuring that each kanetsugu knife offers a superior user experience. The brand has also been responsive to global culinary trends, expanding their range to include specialized knives for various cuisines and techniques, maintaining relevance in an ever-changing industry.

Furthermore, the digital age has allowed Kanetsugu to share their story and craftsmanship with a global audience, expanding their reach far beyond Japan. This global exposure has cemented the kanetsugu knife‘s reputation as a world-class tool, sought after by discerning chefs in renowned restaurants and passionate home cooks alike. The brand has adapted its marketing and distribution strategies to meet international demand while upholding its core values of quality and heritage. This adaptability has been key to their enduring success.

The company’s commitment to research and development remains strong, continually seeking new ways to improve the performance and aesthetics of their knives. They frequently collaborate with metallurgical experts and professional chefs to gather feedback and incorporate it into their design process. This iterative approach to innovation ensures that the kanetsugu knife remains at the cutting edge of culinary tool technology. The integration of customer feedback directly influences the practical usability and effectiveness of their products.

From the early days of simple yet sturdy blades to today’s sophisticated, high-performance instruments, the evolution of the kanetsugu knife is a story of relentless pursuit of perfection. It is a testament to the foresight of its founders and the dedication of generations of artisans who have upheld a legacy of excellence, ensuring that the kanetsugu knife continues to define the pinnacle of Japanese cutlery. This continuous refinement, combined with deep respect for tradition, ensures the brand’s lasting impact on the culinary world.

Philosophy and Vision: The Heart Behind Every Kanetsugu Blade

At the core of every kanetsugu knife lies a profound philosophy that marries traditional Japanese craftsmanship with relentless innovation. The vision of Kanetsugu is not merely to produce sharp blades, but to create tools that empower chefs, enhance culinary experiences, and stand as enduring testaments to the art of blade making. This philosophy is deeply rooted in the concept of “monozukuri,” a Japanese term that encompasses the entire process of manufacturing, emphasizing skill, spirit, and pride in production. For Kanetsugu, it means pouring passion into every single piece, ensuring a kanetsugu knife is not just a product, but a masterpiece.

The company’s commitment to quality is unwavering, starting from the meticulous selection of raw materials. Only the finest steels, chosen for their purity, hardness, and edge retention capabilities, are deemed worthy of becoming a kanetsugu knife. This rigorous selection process is the first step in ensuring the superior performance that customers have come to expect. They understand that a great knife begins with great ingredients, just as a great meal does, making the initial material choice critically important.

Beyond material selection, Kanetsugu’s vision emphasizes the human element in craftsmanship. While modern technology plays a role, the hands of skilled artisans are indispensable. Each kanetsugu knife undergoes numerous manual processes, from forging and shaping to grinding and sharpening, where the experience and intuition of master craftsmen are paramount. This blend of human touch and technological precision allows for a level of refinement that automated processes alone cannot achieve. It’s this balance that gives a kanetsugu knife its unique character.

Innovation is another cornerstone of Kanetsugu’s philosophy. While deeply respectful of tradition, the company continually invests in research and development to explore new steels, advanced heat treatment methods, and improved blade geometries. Their pioneering work with ZDP-189 steel and the unique Hamaguri-ba (convex) grind are prime examples of this forward-thinking approach. This drive for innovation ensures that the kanetsugu knife remains at the cutting edge of performance, constantly pushing boundaries while staying true to their heritage. This dynamic interplay of past and future defines their development.

The user experience is central to their design philosophy. Kanetsugu engineers their knives not just for sharpness, but for optimal balance, comfort, and control. Every curve of the handle, every angle of the blade, is carefully considered to minimize fatigue and maximize efficiency for the chef. The goal is to create a kanetsugu knife that feels like a natural extension of the user’s hand, allowing for effortless precision and joyful cooking. This human-centric design approach is what truly distinguishes their products in a crowded market.

Furthermore, Kanetsugu holds a vision of sustainability and longevity. They believe that a high-quality kanetsugu knife should be an investment that lasts a lifetime, reducing the need for frequent replacements and promoting a more sustainable consumption pattern. This commitment to durability is reflected in their robust construction and the use of materials designed to withstand the rigors of professional use. They encourage proper knife care and maintenance, emphasizing the value of preserving such a finely crafted tool.

In essence, the philosophy behind the kanetsugu knife is a holistic pursuit of excellence: combining centuries-old wisdom with modern science, human artistry with precise engineering, and a deep respect for both the materials and the end-user. It’s a vision that transforms a simple cutting tool into a cherished companion, embodying the heart and soul of Japanese craftsmanship. This dedication to crafting more than just a tool is why a kanetsugu knife resonates so deeply with culinary professionals and enthusiasts around the world, making it a symbol of true mastery.

Steel, Structure, and Science: The Kanetsugu Knife Blade Unpacked

Decoding Kanetsugu Knife Steels: ZDP-189, VG-10, and Beyond

The heart of any exceptional knife lies in its steel, and the kanetsugu knife distinguishes itself through its mastery of various premium alloys, most notably ZDP-189 and VG-10. Each steel type is chosen for specific properties that contribute to the overall performance and characteristics of the blade, catering to different preferences and demands of culinary professionals. Understanding these materials is key to appreciating the superior cutting ability and durability of a kanetsugu knife.

ZDP-189 is often considered a “super steel” in the knife world, and Kanetsugu was one of the pioneers in its application for kitchen knives. Developed by Hitachi Metals, ZDP-189 boasts an incredibly high carbon content (around 3%) and a high chromium content (around 20%), allowing it to achieve extreme hardness, often reaching 67-68 HRC (Rockwell Hardness Scale). This hardness translates directly into unparalleled edge retention, meaning a kanetsugu knife made from ZDP-189 will hold its razor sharpness for significantly longer periods, even under heavy use. However, its extreme hardness also means it can be more challenging to sharpen and is less forgiving to impacts or twisting motions, requiring careful handling.

VG-10, another popular choice for the kanetsugu knife, is a high-carbon cobalt stainless steel, also from Takefu Special Steel Co., Ltd.. It offers an excellent balance of properties: good hardness (typically 60-61 HRC), impressive edge retention, and superior corrosion resistance. This makes VG-10 an incredibly versatile and forgiving steel, suitable for a wide range of kitchen tasks and ideal for chefs who prioritize a low-maintenance, reliable blade. A kanetsugu knife crafted from VG-10 often features a Damascus cladding, where layers of softer stainless steel are folded over the VG-10 core, adding both aesthetic beauty and additional protection to the hard core.

Beyond these two prominent steels, Kanetsugu also utilizes other high-quality alloys, sometimes in specific series or for particular knife types. These can include **AUS-8**, a good entry-level stainless steel known for its toughness and ease of sharpening, often found in more affordable yet still highly functional kanetsugu knife models. They might also employ other proprietary or less common powdered metallurgy steels that offer unique combinations of properties. The choice of steel is always deliberate, aligning with the intended use and performance profile of each specific kanetsugu knife.

The expertise of Kanetsugu lies not just in selecting these premium steels but in their ability to unlock their full potential through meticulous heat treatment. The transformation of raw steel into a high-performance blade is a delicate process, and Kanetsugu’s deep understanding of metallurgy allows them to achieve optimal hardness, toughness, and grain structure for each steel type. This is what truly differentiates a Kanetsugu blade from others using similar materials. The precision in this thermal processing is a critical factor in the final performance of the kanetsugu knife.

For those seeking the absolute pinnacle of edge retention, a kanetsugu knife made from ZDP-189 is an unparalleled choice, offering an almost unbelievable ability to stay sharp. For everyday professional use where a balance of performance, ease of maintenance, and corrosion resistance is key, the VG-10 kanetsugu knife provides exceptional value and reliability. Kanetsugu’s commitment to offering a range of high-performance steels ensures that every chef can find a kanetsugu knife perfectly suited to their individual needs and preferences, solidifying their reputation as masters of steel selection and manipulation. This dedication to material science truly sets the kanetsugu knife apart from its competitors.

Blade Geometry and Edge Technology: Honbazuke Sharpening and Convex Grinds

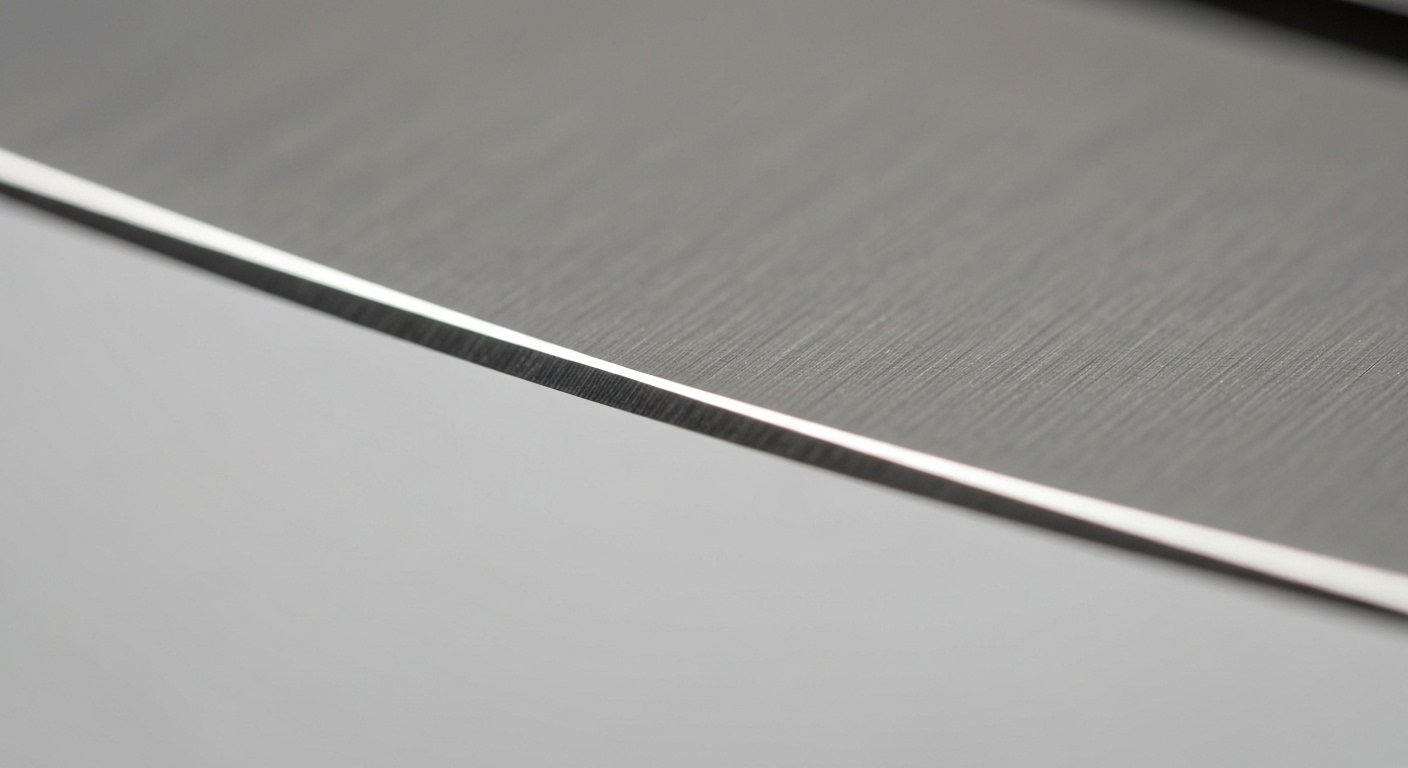

The cutting performance of a kanetsugu knife is not solely dependent on the quality of its steel; it is equally, if not more, influenced by its meticulous blade geometry and advanced edge technology. Kanetsugu employs sophisticated techniques, including Honbazuke sharpening and unique convex grinds, to create blades that offer unparalleled cutting efficiency and remarkable durability. These elements work in harmony to define the superior experience of using a kanetsugu knife.

Honbazuke sharpening is a traditional Japanese sharpening method that involves multiple stages of hand-grinding and polishing on water stones to create an incredibly sharp and precise edge. This painstaking process, performed by highly skilled artisans, ensures that the blade’s edge is refined to a microscopic level, resulting in a keenness that slices through ingredients with minimal resistance. Unlike machine sharpening, Honbazuke allows for subtle adjustments to the edge angle and profile, optimizing it for its intended use. Every kanetsugu knife benefits from this meticulous attention to detail at the final sharpening stage, ensuring it is ready for immediate professional use.

Kanetsugu is particularly renowned for its innovative use of convex grinds, often referred to as “Hamaguri-ba” or clam-shaped edge. Unlike typical V-shaped or flat grinds, a convex grind features a gentle, outward curve from the spine to the edge. This unique geometry reduces friction as the blade passes through food, preventing sticking and allowing for smoother, more effortless cuts. The convex shape also makes the edge incredibly robust and resistant to chipping, even when subjected to lateral stress during cutting. This combination of sharpness and durability is a hallmark of the kanetsugu knife, making it a formidable tool in any kitchen.

The subtle curvature of the Hamaguri-ba ensures that the blade “wedges” food apart rather than simply pushing through it, minimizing cellular damage and preserving the integrity of delicate ingredients. This is especially beneficial for precision tasks such as slicing fish for sashimi or finely dicing vegetables, where clean cuts are paramount. The design philosophy behind this specific geometry is to reduce resistance and enhance the blade’s ability to glide through various textures. This thoughtful engineering is a key differentiator for the kanetsugu knife.

Furthermore, the blend of Honbazuke sharpening and the convex grind results in an edge that not only starts out incredibly sharp but also maintains its sharpness for longer periods. The convex profile provides more material behind the edge, supporting it and making it less prone to rolling or deforming. When the time eventually comes to resharpen, the convex profile allows for easier maintenance and can often be brought back to its original keenness with fewer passes on the stones. This ease of maintenance is a significant advantage for a professional Japanese knife sharpening stone user.

The meticulous attention to blade geometry extends beyond the primary edge to the overall taper and distal grind of the blade. Kanetsugu carefully controls the thickness of the blade from spine to edge and from heel to tip, ensuring optimal balance and flexibility where needed. This precise engineering contributes to the overall nimble feel and superior cutting performance of a kanetsugu knife, making it a joy to wield even during long hours of food preparation. Every aspect of the blade’s shape is optimized for performance.

In essence, the mastery of blade geometry and edge technology is a critical pillar of Kanetsugu’s excellence. By combining the ancient art of Honbazuke sharpening with their innovative convex grinds, they create a kanetsugu knife that is not just sharp, but supremely efficient, durable, and a pleasure to use. This scientific approach to blade design, steeped in tradition, solidifies the kanetsugu knife‘s position as a leader in high-performance culinary tools, demonstrating that true innovation often lies in perfecting fundamental principles.

Heat Treatment Mastery: Unlocking Peak Performance in Kanetsugu Knives

The science of heat treatment is arguably the most critical factor in unlocking the full potential of any knife steel, and Kanetsugu’s expertise in this area is a cornerstone of the exceptional performance of the kanetsugu knife. Even the finest steel can underperform if not properly heat treated, and conversely, masterful heat treatment can elevate a good steel to outstanding levels. Kanetsugu’s proprietary processes ensure that each blade achieves its optimal hardness, toughness, and edge retention, defining the durability and precision of every kanetsugu knife.

Heat treatment involves a precise sequence of heating and cooling cycles that transform the microstructure of the steel. This process typically includes three main stages: hardening, quenching, and tempering. For a kanetsugu knife, these stages are meticulously controlled, often involving advanced furnaces and precise temperature monitoring systems. The goal is to create a fine, uniform grain structure within the steel and to convert soft phases into hard, wear-resistant phases like martensite. This intricate dance of temperature and time is crucial for developing the desired properties of the blade.

In the hardening phase, the blade is heated to a very specific temperature, often hundreds of degrees Celsius, where its atomic structure becomes austenitic. The exact temperature varies significantly depending on the steel type; for instance, ZDP-189, with its high carbon content, requires different parameters than VG-10. Kanetsugu’s metallurgists have a deep understanding of these specific requirements for each steel grade used in a kanetsugu knife, ensuring optimal preparation for the next critical step. Precision at this stage is paramount for the subsequent transformation.

Quenching, the rapid cooling of the heated blade, is where the steel’s crystal structure transforms into the desired hard martensite. This can involve cooling in oil, air, or even cryogenic temperatures for some high-performance steels. Kanetsugu’s mastery of quenching techniques minimizes internal stresses and prevents unwanted deformation, ensuring the blade maintains its integrity and shape. For certain steels, deep cryogenic treatment is employed, which involves cooling the blade to extremely low temperatures (e.g., in liquid nitrogen). This further enhances the conversion of retained austenite into martensite, boosting hardness and wear resistance, especially for advanced alloys used in a kanetsugu knife.

Finally, tempering is a critical step that follows quenching. The blade is reheated to a lower temperature, which slightly reduces its hardness but significantly increases its toughness and ductility, making it less brittle and more resistant to chipping. This delicate balance between hardness and toughness is crucial for a kitchen knife, which must be both extremely sharp and resilient enough to withstand daily use. Kanetsugu’s tempering protocols are fine-tuned for each steel, ensuring that the kanetsugu knife offers both exceptional edge retention and practical durability, allowing it to perform consistently over time.

The expertise in heat treatment is not just about following a recipe; it’s about understanding the subtle nuances of each batch of steel and adjusting parameters accordingly. Kanetsugu employs experienced technicians who monitor these processes with extreme precision, ensuring uniformity across their production. This commitment to scientific rigor and meticulous execution is what allows a kanetsugu knife to deliver consistent, top-tier performance, setting it apart from lesser-made blades that might use similar materials but lack the same level of thermal processing expertise.

In conclusion, the sophisticated heat treatment methods employed by Kanetsugu are fundamental to the superior characteristics of the kanetsugu knife. It’s the unseen magic that transforms raw steel into a razor-sharp, incredibly durable, and high-performing culinary tool. This mastery ensures that every kanetsugu knife is not just a piece of metal, but a finely tuned instrument, ready to meet the rigorous demands of professional kitchens and passionate home cooks worldwide, promising an elevated cutting experience with every use.

Signature Series Spotlight: A Portfolio of Kanetsugu Excellence

The Precision and Versatility of Kanetsugu Pro-M and Pro-S Series

Within the extensive portfolio of Kanetsugu, the Pro-M and Pro-S series stand out as workhorses for professional chefs and serious home cooks, embodying the brand’s commitment to precision, versatility, and enduring performance. These series are designed to offer an exceptional balance of features, making them highly adaptable for a wide array of culinary tasks. Each kanetsugu knife in these lines is a testament to meticulous craftsmanship and practical design, tailored for demanding kitchen environments.

The Kanetsugu Pro-M Series is often celebrated for its superb cutting ability and robust construction, making it an ideal choice for chefs seeking a reliable and high-performing everyday knife. Blades in this series are typically crafted from high-carbon Molybdenum Vanadium stainless steel, which offers a great combination of sharpness, excellent edge retention, and impressive corrosion resistance. This steel is heat-treated to achieve a hardness of around 58-59 HRC, providing a balance that allows for easy sharpening while maintaining a durable edge for prolonged use. A kanetsugu knife from the Pro-M line is known for its resilience.

Key to the Pro-M’s performance is its unique blade geometry, featuring Kanetsugu’s signature Hamaguri-ba (convex) grind. This clam-shaped edge significantly reduces cutting resistance, allowing the blade to glide through ingredients with remarkable ease and minimizing food sticking. The handles in the Pro-M series are often made from high-quality, water-resistant Pakkawood or composite materials, shaped for an ergonomic grip that provides comfort and control even during extended periods of use. The full-tang construction of each kanetsugu knife in this series ensures superior balance and durability, making it a professional’s dependable companion.

On the other hand, the Kanetsugu Pro-S Series often targets a slightly different niche, sometimes featuring steels that offer slightly enhanced properties or design variations for specific user preferences. While sharing the core principles of the Pro-M, the Pro-S series might incorporate subtle refinements in handle design or blade profile, aiming for an even more refined cutting experience. It could also lean into lighter designs or different balance points, catering to chefs with varied preferences for their everyday kanetsugu knife. The precise differences between Pro-M and Pro-S can vary by model year or regional availability, but both uphold Kanetsugu’s high standards.

Both the Pro-M and Pro-S series offer a comprehensive range of knife types, from versatile Gyutos (chef’s knives) and Santokus (all-purpose kitchen knives) to specialized utility knives, paring knives, and bread knives. This breadth of selection ensures that a chef can build a complete set of high-quality tools, all bearing the consistent performance and aesthetic of a kanetsugu knife. The versatility of these series makes them suitable for a wide array of culinary tasks, from intricate slicing to robust chopping.

The precision engineering evident in both series guarantees clean, effortless cuts, which is crucial for food presentation and preserving ingredient texture. The sharp edges and thoughtful design contribute to safer knife handling, as less force is required to make cuts. This combination of attributes makes a kanetsugu knife from the Pro-M or Pro-S series a valuable investment for any kitchen. Their ease of sharpening also contributes to their popularity, allowing users to maintain peak performance with minimal effort. This practical aspect is highly valued in busy professional settings.

In summary, the Kanetsugu Pro-M and Pro-S series exemplify the brand’s dedication to creating functional artistry. They are designed not just to perform, but to excel in the rigorous environment of professional culinary arts, offering a perfect blend of high-performance steel, ergonomic design, and superb cutting geometry. Choosing a kanetsugu knife from these lines means investing in a tool that will consistently deliver precision and versatility, supporting culinary endeavors for years to come and reinforcing the brand’s reputation for excellence.

The Exceptional Edge Retention of the Kanetsugu ZDP-189 Series

For culinary professionals who prioritize ultimate edge retention and cutting performance above all else, the Kanetsugu ZDP-189 Series stands as a pinnacle of metallurgical innovation and master craftsmanship. These knives are specifically designed to push the boundaries of what a kitchen knife can achieve in terms of sharpness longevity, making them an unparalleled choice for demanding tasks and extended use. A kanetsugu knife from this series represents the zenith of the brand’s commitment to cutting-edge material science.

At the heart of this series is ZDP-189 steel, a revolutionary powdered metallurgy super steel developed by Hitachi Metals. What sets ZDP-189 apart is its incredibly high carbon (around 3%) and chromium (around 20%) content, which allows it to achieve extreme hardness, often reaching an astonishing 67-68 HRC on the Rockwell scale. This unprecedented hardness is directly responsible for the legendary edge retention of the kanetsugu knife in this series. Users report that these knives maintain their keen edge for an incredibly long time, far outperforming conventional stainless or even other premium steels.

The manufacturing process for a kanetsugu knife made from ZDP-189 is significantly more complex and resource-intensive due to the steel’s inherent properties. The extreme hardness makes it challenging to grind, shape, and sharpen, requiring specialized machinery and highly skilled artisans. Kanetsugu has invested heavily in the technology and expertise necessary to work with this advanced material, ensuring that every ZDP-189 blade is perfectly formed and finished. The heat treatment process, in particular, is meticulously controlled to unlock the steel’s maximum potential, including often employing cryogenic treatments.

While the edge retention of the ZDP-189 kanetsugu knife is its most defining characteristic, it’s important to understand the trade-offs. The extreme hardness that provides such incredible sharpness longevity also means the steel is less tough than softer alternatives. This makes the ZDP-189 knife more susceptible to chipping if it encounters hard objects (like bones or frozen food) or is used with improper cutting techniques. Therefore, a kanetsugu knife from this series requires a user who understands its capabilities and limitations, employing careful handling and precise cutting movements to preserve its pristine edge.

Despite this, for tasks requiring absolute precision and prolonged keenness—such as slicing delicate proteins, intricate vegetable preparation, or continuous high-volume cutting—the performance of the kanetsugu knife in ZDP-189 is unmatched. Chefs who frequently work with ingredients that challenge the sharpness of ordinary knives find the ZDP-189 series invaluable. Its ability to stay sharp for so long translates into fewer interruptions for sharpening, increased efficiency, and consistently beautiful cuts, elevating the overall culinary output.

The aesthetics of the Kanetsugu ZDP-189 Series knives often complement their high-performance nature. Many feature exquisite Damascus cladding, where layers of softer, more ductile stainless steel are forged over the ZDP-189 core. This not only creates stunning visual patterns but also provides a degree of added protection to the ultra-hard core. The handles are typically crafted from premium materials like Micarta, Pakkawood, or even exotic woods, designed for ergonomic comfort and a luxurious feel, completing the premium experience of holding a kanetsugu knife.

In conclusion, the Kanetsugu ZDP-189 Series is a testament to the brand’s pioneering spirit and unwavering pursuit of ultimate performance. While it demands a certain level of care and respect from its user, the unparalleled edge retention and cutting ability of a kanetsugu knife from this series make it a truly exceptional tool for the discerning professional or enthusiast who values peak performance above all else. It’s an investment in enduring sharpness and a tangible representation of Kanetsugu’s mastery of advanced metallurgy, solidifying its place among the elite of Japanese knife steel innovations.

Exploring Niche Collections and Limited-Edition Kanetsugu Knives

Beyond their established and celebrated Pro-M, Pro-S, and ZDP-189 series, Kanetsugu also delves into specialized niche collections and produces highly coveted limited-edition knives. These unique offerings showcase the brand’s willingness to experiment with rare materials, innovative designs, and unique craftsmanship techniques, appealing to collectors, connoisseurs, and chefs seeking something truly distinctive. Owning a niche or limited-edition kanetsugu knife is often about possessing a piece of culinary history and advanced artistry.

Niche collections often arise from specific needs or a desire to explore unique aesthetic and performance combinations. For instance, Kanetsugu might develop a series optimized for specific regional cuisines, such as a traditional Yanagiba or Deba set with unique steel compositions or handle materials not found in their standard lines. These collections might feature hand-forged blades using traditional methods like Aogami (Blue Steel) or Shirogami (White Steel) from Hitachi Metals, catering to purists who appreciate the nuanced performance of carbon steel. A kanetsugu knife from such a collection provides a distinct experience.

These niche series often incorporate exotic handle materials, such as stabilized burl woods, intricate composites, or even traditional Japanese lacquered handles (Urushi), elevating the knife beyond a mere tool to a functional work of art. The attention to detail in these collections is often intensified, with hand-polished spines, mirror-finished bevels, and custom-engraved bolsters. Such a kanetsugu knife is not only a high-performance instrument but also a display piece, reflecting immense dedication to both utility and beauty.

Limited-edition kanetsugu knife releases are even more exclusive, often produced in very small batches (sometimes as few as a few dozen units) and released only once. These editions might commemorate a special anniversary, showcase a collaboration with a renowned chef or artisan, or feature experimental materials and designs that are too costly or complex for regular production. For example, a limited-edition kanetsugu knife might feature a blade crafted from a rare powdered steel alloy, clad in an unusually high number of Damascus layers, or adorned with precious metal inlays.

The allure of limited-edition Kanetsugu knives lies in their scarcity and their unique attributes. They represent the pinnacle of the brand’s innovation and craftsmanship, often incorporating cutting-edge technology or reviving ancient techniques. These knives are highly sought after by collectors worldwide, not just for their investment value but for the sheer pleasure of owning a truly exceptional and rare culinary tool. Each limited-edition kanetsugu knife tells a unique story of innovation and artistry, representing a moment in time for the brand.

Acquiring a niche or limited-edition kanetsugu knife typically requires vigilance, as they are often announced through specialized channels and sell out quickly. Enthusiasts frequently follow Kanetsugu’s official announcements or reputable dealers specializing in high-end Japanese cutlery. These knives serve as a testament to Kanetsugu’s continuous push for excellence and their deep connection to the rich tradition of Japanese blade making. They underscore that a kanetsugu knife is not just a uniform product, but a spectrum of possibilities, from the everyday workhorse to the collectible masterpiece.

In essence, these special collections and limited runs showcase Kanetsugu’s dedication to both preserving historical techniques and exploring the future of knife design. They offer a unique opportunity for enthusiasts to own a piece of cutting-edge innovation or a tribute to timeless artistry. Whether a chef is seeking a specific performance characteristic or a collector is looking for a rare addition, these distinctive offerings reinforce the reputation of the kanetsugu knife as a symbol of unparalleled quality and exclusivity in the culinary world.

Ergonomics, Balance, and User Experience: Beyond the Kanetsugu Blade

Handle Materials and Construction: Comfort and Durability in Every Kanetsugu Knife

While the blade is often the star of a knife, the handle is equally crucial for comfort, control, and overall user experience. Kanetsugu understands this implicitly, meticulously designing and constructing the handles of every kanetsugu knife to provide optimal ergonomics and enduring durability. The choice of handle material and the method of its construction significantly impact how a knife feels in the hand, its balance, and its longevity, especially in demanding professional kitchen environments.

Kanetsugu utilizes a variety of high-quality materials for their knife handles, each selected for specific properties. One common choice is Pakkawood, a composite material made from layers of hardwood veneers impregnated with resin and compressed under high pressure. Pakkawood is highly durable, water-resistant, and dimensionally stable, making it ideal for kitchen use where moisture exposure is common. It also offers a beautiful aesthetic, often mimicking the look of natural wood grain while providing superior resistance to warping or cracking, ensuring the comfort and stability of a kanetsugu knife handle over time.

Another popular material is Micarta, a composite of linen, canvas, or paper fibers embedded in a thermosetting plastic. Similar to Pakkawood, Micarta is incredibly tough, moisture-resistant, and impervious to chemicals. It can be textured to provide an excellent grip, even when wet, which is a significant advantage in a busy kitchen. The material also develops a subtle patina with use, enhancing its aesthetic appeal over time. A kanetsugu knife with a Micarta handle offers a robust and dependable grip that withstands rigorous daily use, ensuring long-term comfort and control.

For some premium or traditional series, Kanetsugu may use natural wood handles, such as Walnut, Rosewood, or Magnolia (Ho wood). These materials offer a classic aesthetic and a warm, natural feel in the hand. While requiring a bit more care to prevent moisture damage, the beauty and tactile experience of a natural wood handle are unmatched for many traditionalists. These handles are often paired with a traditional Japanese “wa” handle shape, which is octagonal or D-shaped, designed to fit snugly in the palm and provide excellent control for precise cutting, enhancing the authentic feel of a kanetsugu knife.

The construction method of the handle is just as important as the material. Kanetsugu primarily employs two main types: full-tang and half-tang (or hidden-tang) designs. In full-tang construction, the steel of the blade extends fully through the entire length of the handle, mirroring its shape. This provides superior strength, balance, and durability, as the handle scales are riveted directly to the tang. Many professional-grade kanetsugu knife series, like the Pro-M, feature full-tang construction due to its inherent robustness and balance, making it ideal for heavy-duty tasks where resilience is key.

Half-tang or hidden-tang construction, often found in traditional Japanese “wa” handles, involves the tang extending partially into the handle, usually tapering to a thin point. While seemingly less robust, this construction method can offer lighter weight and a different balance point, often favoring the blade, which many traditionalists prefer. The tang is typically secured with strong epoxy, providing a durable bond. A kanetsugu knife with a hidden tang often allows for a more “blade-heavy” balance, which some chefs find ideal for rock-chopping or specific Japanese cutting techniques, providing a distinct feel during use.

Regardless of the material or construction, Kanetsugu’s commitment to flawless fit and finish ensures that there are no gaps between the handle and the bolster, preventing food particles and moisture from accumulating. This hygienic design not only enhances safety but also contributes to the longevity of the kanetsugu knife. The careful shaping and polishing of each handle reduce hot spots and provide a comfortable, secure grip, even during extended periods of use. This attention to minute details ensures that the handle is not just an attachment but an integral part of the knife’s high performance and user satisfaction.

The Art of Balance: Achieving Optimal Control and Fatigue Reduction

In the world of professional culinary arts, a knife is an extension of the chef’s hand, and its balance is paramount to achieving optimal control, precision, and minimizing fatigue during long hours of food preparation. Kanetsugu excels in the art of balance, meticulously designing each kanetsugu knife to possess a weight distribution that feels natural and effortless in the user’s hand. This deliberate engineering transforms a simple cutting tool into a highly responsive instrument, making the user experience intuitive and less strenuous.

The “balance point” of a knife refers to the spot along the blade and handle where the knife feels perfectly weighted when held. For most Western-style chef’s knives, including many kanetsugu knife models with full-tang construction, the ideal balance point is typically at or just forward of the bolster (the junction between the blade and the handle). A well-balanced knife minimizes the effort required to manipulate it, allowing for fluid movements and precise cuts. When the balance is off, the knife can feel unwieldy, causing the user to exert more force, leading to quicker fatigue and reduced accuracy.

Kanetsugu achieves this optimal balance through a combination of thoughtful design elements. The choice of handle materials, their density, and their specific volume all play a role. Heavier handle materials like Micarta or Pakkawood, when used with a full tang, provide a robust counterweight to the blade. Conversely, lighter handle materials on traditional “wa” handles often shift the balance slightly forward, which some chefs prefer for a “blade-heavy” feel, enabling them to leverage the weight of the blade for chopping tasks. The precise shaping and tapering of the blade also contribute to the overall feel and balance of a kanetsugu knife.

The ergonomic design of the handle works in tandem with the balance to reduce fatigue. A handle that fits comfortably in the hand, without sharp edges or awkward contours, allows for a relaxed grip, even during repetitive motions. When the knife is properly balanced, the user doesn’t have to strain their wrist or grip the handle too tightly to control the blade. This reduction in physical exertion is crucial for professional chefs who spend entire shifts with a knife in hand, making a well-balanced kanetsugu knife an invaluable asset for long-term comfort and productivity.

For example, a Gyuto (Japanese chef’s knife) from Kanetsugu is often designed to have a balance that supports the “rocking” motion common in Western cutting techniques, where the blade pivots on its tip. This requires a slightly more forward balance. In contrast, a traditional Japanese knife like a Yanagiba might have a more blade-heavy balance, suited for long, single-pull slicing motions. Kanetsugu’s understanding of these nuanced requirements for different knife types highlights their dedication to practical ergonomics, ensuring each kanetsugu knife is purpose-built for its intended function.

The impact of proper balance extends beyond just comfort; it directly influences safety and precision. A well-balanced knife provides better control, reducing the risk of slips or miscuts. It allows for more precise articulation of the blade, enabling delicate tasks like fine brunoise or intricate garnishes to be executed with greater ease and confidence. This level of control is a hallmark of the kanetsugu knife, distinguishing it as a tool that genuinely enhances the chef’s capabilities rather than hindering them.

In essence, the art of balance in a kanetsugu knife is a testament to Kanetsugu’s holistic design philosophy. It’s not just about a sharp edge, but about creating an instrument that feels like a natural extension of the user’s arm, maximizing comfort, control, and efficiency. This meticulous attention to the subtle dynamics of weight distribution and handle design is what truly elevates a kanetsugu knife into a professional’s trusted companion, ensuring peak performance and reduced strain throughout countless hours in the kitchen.

Real-World Performance: Long-Term Insights from Kanetsugu Knife Users

The true measure of any culinary tool lies in its real-world performance, enduring the rigorous demands of daily kitchen use. For the kanetsugu knife, long-term insights from professional chefs and dedicated home cooks consistently affirm its reputation for exceptional performance, durability, and a superior user experience. These testimonials highlight how a kanetsugu knife stands up to the test of time, proving its value as a significant investment in a high-quality kitchen tool.

One of the most frequently praised aspects of the kanetsugu knife is its remarkable edge retention. Users, especially those with ZDP-189 models, report that their knives stay incredibly sharp for extended periods, even with heavy use on a variety of ingredients. This means less frequent sharpening, saving valuable time and effort in a busy professional kitchen. Chefs appreciate that they can rely on their kanetsugu knife to maintain its keen edge through an entire service, reducing the need for constant touch-ups on a honing rod.

Beyond initial sharpness, the cutting feel of a kanetsugu knife receives consistent accolades. The distinctive Hamaguri-ba (convex) grind is frequently cited for its ability to glide through food with minimal resistance, preventing sticking and making even mundane tasks feel effortless. Chefs often describe the experience as “smooth” or “like cutting through butter,” whether they are slicing delicate fish or chopping dense root vegetables. This efficiency translates directly into faster prep times and cleaner cuts, which is crucial for both presentation and food safety. The ergonomic design further contributes to this ease of use.

Durability is another key theme in user feedback. Despite their incredible sharpness, kanetsugu knife blades are engineered to be resilient. While high-carbon super steels like ZDP-189 require careful handling to avoid chipping, users report that, with proper care and technique, these knives withstand the rigors of professional use exceptionally well. The robust construction, especially of full-tang models, instills confidence that the knife can handle demanding tasks without structural compromise. This longevity means that a kanetsugu knife is not a disposable item, but a lasting asset in the kitchen.

The comfort and balance of the kanetsugu knife handles are also highly valued, especially by those who spend hours wielding them. Users consistently report reduced hand and wrist fatigue, even during prolonged periods of chopping and slicing. The thoughtful design, which considers the natural grip and weight distribution, allows for a more relaxed hold, enhancing control and reducing strain. This ergonomic excellence is a major factor in the kanetsugu knife‘s appeal, making it a comfortable companion for long shifts.

Furthermore, the aesthetic appeal of a kanetsugu knife, particularly those with stunning Damascus patterns, is frequently mentioned. While secondary to performance, the visual beauty adds to the pride of ownership and the overall enjoyment of using the knife. Many chefs view their kanetsugu knife as a functional piece of art, a reflection of their passion for the culinary craft, and a topic of conversation among colleagues and customers. This blend of form and function elevates the user experience beyond mere utility.

In summary, the real-world performance of the kanetsugu knife consistently exceeds expectations, validating its position as a top-tier culinary tool. From its unmatched edge retention and effortless cutting to its ergonomic comfort and robust durability, user insights confirm that a kanetsugu knife is a long-term investment that pays dividends in efficiency, precision, and sheer cutting pleasure. It’s a testament to Kanetsugu’s unwavering commitment to crafting blades that not only meet but often surpass the demanding requirements of the culinary world.

Distinguishing Authenticity and Care: Preserving Your Kanetsugu Knife Investment

Identifying Genuine Kanetsugu Knives: Safeguarding Against Counterfeits

As the reputation of the kanetsugu knife has grown globally, so too has the unfortunate emergence of counterfeit products. Safeguarding your investment and ensuring you receive a genuine kanetsugu knife of authentic quality requires diligence and awareness of key indicators. Counterfeit knives not only lack the superior performance and durability of the real thing but can also be made with inferior materials, potentially posing safety risks. Understanding how to identify an authentic kanetsugu knife is crucial for any discerning buyer.

The first and most reliable method to ensure authenticity is to purchase your kanetsugu knife from authorized dealers or directly from the official Kanetsugu website. Reputable knife retailers, whether online or brick-and-mortar, have established relationships with the manufacturer and can guarantee the provenance of their products. Be wary of unusually low prices from unknown sellers or marketplaces, as these are often red flags for counterfeit goods. The investment in a kanetsugu knife is significant, and attempting to save a small amount can lead to purchasing a vastly inferior product.

Examine the knife’s packaging and documentation. Genuine kanetsugu knife products typically come in well-designed, sturdy packaging that features clear branding, model numbers, and often includes care instructions or a certificate of authenticity. Counterfeit packaging might appear flimsy, have blurry printing, misspellings, or inconsistent branding. Pay attention to the details; even small discrepancies can indicate a fake. Authentic products always demonstrate a consistent level of quality in their presentation, reflecting the meticulous standards of the kanetsugu knife itself.

Inspect the knife itself for hallmarks of quality and craftsmanship. A genuine kanetsugu knife will exhibit flawless fit and finish. This means no visible gaps between the blade and handle, smooth and perfectly aligned handle scales, and a uniformly sharp, well-polished edge. The Kanetsugu logo and model markings on the blade should be crisp, precisely etched or laser-engraved, not blurry or unevenly applied. Counterfeit knives often show signs of hurried production, such as rough finishes, uneven grinds, or poorly applied branding. The devil is truly in the details when assessing a kanetsugu knife.

The aesthetic quality of the blade, particularly for Damascus patterns, is another indicator. Genuine Damascus on a kanetsugu knife will have a distinct, often three-dimensional pattern created by layers of different steels being folded and forged. Counterfeit Damascus is often merely a surface etching or a cheap printed pattern that lacks depth and character. Learning to distinguish true pattern welding from superficial markings can save you from a disappointing purchase. The depth and clarity of the layers are hard to replicate cheaply, making them a strong sign of a genuine kanetsugu knife.

Lastly, trust your instincts and research. If an offer seems too good to be true, it likely is. Take the time to compare images of the knife you are considering with authentic models on the official Kanetsugu website or from trusted reviewers. Read user reviews on reputable forums to learn from the experiences of others. By being informed and exercising caution, you can confidently acquire a genuine kanetsugu knife that will perform as expected and maintain its value as a true investment in culinary excellence. Protecting your purchase of a kanetsugu knife ensures you truly experience its renowned quality.

Essential Maintenance and Sharpening for Your Kanetsugu Knife

A kanetsugu knife is an investment in precision and performance, and like any high-quality tool, it requires proper maintenance and sharpening to retain its exceptional qualities over a lifetime of use. Neglecting care can quickly diminish its edge retention, lead to corrosion, or even damage the blade. Adhering to essential care practices ensures your kanetsugu knife remains a pinnacle of culinary excellence, serving you faithfully for decades.

Immediate Cleaning: Always clean your kanetsugu knife immediately after use. Wash it by hand with warm water and a mild dish soap, using a soft cloth or sponge. Avoid abrasive scrubbers that can scratch the blade or handle. Never put a kanetsugu knife in a dishwasher. Dishwashers expose knives to harsh detergents, high heat, and potential collisions with other items, which can dull the edge, corrode the steel, and damage handle materials. Hand washing prevents these issues and is a fundamental step in preserving your kanetsugu knife‘s integrity.

Thorough Drying: After washing, thoroughly dry your kanetsugu knife immediately with a clean, soft towel. This is especially critical for carbon steel blades (which are more prone to rust) and for any knife, regardless of steel type, to prevent water spots and potential corrosion. Allowing a knife to air dry or sit wet can lead to pitting or discoloration, compromising both its performance and aesthetics. Ensure the blade and handle are completely dry before storage, which is vital for any kanetsugu knife.

Proper Storage: Store your kanetsugu knife safely to protect its edge and prevent accidents. Ideal storage solutions include a wooden knife block, a magnetic knife strip (ensuring the blade doesn’t clang against other knives), in-drawer knife organizers, or blade guards/saya (wooden sheaths). Avoid storing knives loosely in a drawer where they can bump against other utensils, damaging their delicate edge and posing a safety hazard. Proper storage ensures your kanetsugu knife remains sharp and safe.

Sharpening and Honing: Regular honing and periodic sharpening are essential. A honing rod (ceramic or fine steel) is used to realign a slightly dull edge that has rolled over from use; it doesn’t remove much metal. Use a honing rod frequently (e.g., before each use or after every few uses) with light pressure, following the knife’s original angle. For true sharpening, when the edge has lost its keenness and honing is no longer sufficient, use Japanese water stones. These provide the best results for a kanetsugu knife, allowing for precise control and a razor-sharp finish. Start with a coarser grit stone to restore the edge, then progress to finer grits for refinement and polishing. For ZDP-189 steel, a coarser diamond stone or professional sharpening service may be required due to its extreme hardness, ensuring your kanetsugu knife maintains its incredible cutting ability.

Cutting Surface: Always use your kanetsugu knife on appropriate cutting surfaces. Wooden or high-quality plastic cutting boards are ideal as they are softer than the knife’s edge and will not dull it quickly. Avoid hard surfaces like glass, ceramic, stone, or metal, which can immediately roll or chip your blade’s delicate edge. A proper cutting surface is as important as proper sharpening in maintaining the longevity and sharpness of your kanetsugu knife. This simple practice will dramatically extend its life.

By integrating these essential maintenance and sharpening practices into your routine, you can ensure that your kanetsugu knife not only retains its legendary sharpness and performance but also remains a cherished and reliable tool in your kitchen for many years to come. Treating your investment with care ensures it continues to perform at its peak, making every cut a pleasure.

The Longevity of a Kanetsugu Knife: What to Expect Over Years of Use

Investing in a high-quality kanetsugu knife is not just purchasing a tool; it’s acquiring a companion for your culinary journey, designed for remarkable longevity. With proper care and maintenance, a kanetsugu knife is built to last not just years, but often a lifetime, becoming a treasured heirloom passed down through generations. Understanding what to expect over years of use helps appreciate the true value and enduring quality of this Japanese masterpiece.

Initially, a new kanetsugu knife will exhibit a razor-sharp edge, perfect fit and finish, and a pristine appearance. Over the first few months of regular use, assuming proper cleaning and storage, the primary change you’ll notice is the gradual need for honing to maintain its keenness. Depending on the steel type (e.g., ZDP-189 will require less frequent honing than VG-10) and frequency of use, you might also introduce your kanetsugu knife to its first proper sharpening session on water stones. This initial period is about breaking in the knife and establishing your care routine.

As the years turn into a decade, a well-maintained kanetsugu knife will still perform exceptionally well. The blade’s edge will continue to respond beautifully to sharpening, allowing it to regain its initial sharpness repeatedly. You might observe a subtle patina developing on carbon steel blades, which is a natural oxidation process that adds character and can actually offer some rust protection. The handle materials, especially natural woods or composites like Micarta, may develop a richer sheen or a comfortable “worn-in” feel that conforms perfectly to your grip. This natural aging process enhances the unique character of your kanetsugu knife.

The structural integrity of a kanetsugu knife, particularly those with full-tang construction, is designed for enduring strength. Rivets in the handle should remain tight, and there should be no loosening of the blade from the handle. The superior heat treatment of the steel ensures the blade maintains its inherent toughness and ability to hold an edge through countless sharpening cycles. This robust construction is a key factor in the long-term reliability of a kanetsugu knife, ensuring it remains a dependable tool for rigorous daily use in professional kitchens.

Over several decades, a kanetsugu knife becomes a testament to its heritage and the artisan’s skill. While cosmetic changes like minor scratches on the blade’s surface or a slightly more pronounced patina are normal, the knife’s core functionality – its ability to take and hold a sharp edge, its balance, and its comfortable feel – should remain undiminished. Any noticeable chips or significant edge damage over this time would typically be due to misuse (e.g., cutting on hard surfaces, dropping the knife) rather than material failure. These are professional tools meant to withstand the test of time when cared for properly.

Ultimately, the longevity of a kanetsugu knife is a direct reflection of its quality craftsmanship and the user’s commitment to care. Unlike mass-produced knives that may dull quickly, require frequent replacement, or suffer structural failures, a Kanetsugu knife is built to be a durable, high-performance asset that matures with its owner. It serves not only as a tool but as a source of pride, embodying a legacy of precision and enduring artistry that can be passed down. This unparalleled lifespan is what truly makes a kanetsugu knife a wise and cherished investment for any culinary enthusiast or professional.

The Enduring Legacy of the Kanetsugu Knife

A Synthesis of Tradition, Innovation, and Unparalleled Performance

The kanetsugu knife stands as a powerful symbol of synergy, brilliantly synthesizing centuries-old Japanese blade-making traditions with relentless modern innovation to deliver unparalleled performance. This intricate blend is what distinguishes Kanetsugu in the competitive world of culinary tools, creating knives that are not merely instruments but masterpieces of functional art. The enduring legacy of the kanetsugu knife is firmly rooted in this harmonious integration of past and future, providing a cutting edge experience unlike any other.

The traditional aspect is deeply ingrained in every kanetsugu knife, tracing its lineage back to the master swordsmiths of Seki City. Techniques like multi-layered steel forging, differential heat treatment, and the meticulous Honbazuke hand-sharpening are direct inheritances from this rich historical past. These time-honored methods are not simply replicated but understood and applied with profound respect for the wisdom of previous generations. This foundational adherence to proven artisanal practices ensures that the core integrity and craftsmanship of a kanetsugu knife remain true to its origins.

However, Kanetsugu is far from being stagnant in its adherence to tradition. The brand continually pushes the boundaries of innovation, embracing advanced metallurgy and cutting-edge design principles. Their pioneering use of super steels like ZDP-189, which offers extreme hardness and edge retention, demonstrates a forward-thinking approach to material science. Furthermore, their development of the unique Hamaguri-ba (convex) grind is a testament to their commitment to optimizing blade geometry for effortless cutting and superior durability. This willingness to experiment and adopt new technologies ensures that the kanetsugu knife remains at the forefront of performance. This blend of the past and the future is what makes a kanetsugu knife truly special.

The result of this synthesis is an unparalleled level of performance. A kanetsugu knife consistently delivers exceptional sharpness, allowing for precise and effortless cuts that enhance both culinary results and the user experience. Its superior edge retention means less time spent sharpening and more time creating, a critical advantage in professional settings. The ergonomic design, optimized balance, and durable construction further contribute to a tool that feels like a natural extension of the chef’s hand, minimizing fatigue and maximizing control. Every aspect of a kanetsugu knife is meticulously engineered for peak function.

This enduring legacy is also built on a philosophy of meticulous quality control and an unwavering dedication to excellence in every single blade. From the careful selection of premium raw materials to the final inspection, Kanetsugu ensures that each kanetsugu knife upholds the brand’s stringent standards. This commitment to consistency and reliability has earned the trust of chefs worldwide, cementing the kanetsugu knife‘s reputation as a dependable and superior culinary instrument, capable of standing up to the most rigorous demands of the kitchen environment.

In conclusion, the kanetsugu knife is more than just a cutting tool; it is a living embodiment of a cultural heritage that embraces progress without sacrificing its soul. It represents a masterful synthesis where the wisdom of tradition informs ingenious innovation, culminating in unparalleled performance that truly sets it apart. This dynamic blend is the core of its enduring legacy, making every kanetsugu knife a testament to the pursuit of perfection in culinary craftsmanship, a true icon in the world of high-performance kitchen knives.

Why a Kanetsugu Knife Remains a Professional’s Choice

For discerning culinary professionals, the choice of a knife is a critical decision that directly impacts their efficiency, precision, and overall enjoyment of their craft. Year after year, the kanetsugu knife consistently remains a top choice for chefs around the globe, a testament to its unwavering quality, exceptional performance, and the trust it has built within the culinary community. Its status as a professional’s preferred instrument is rooted in several key factors that set it apart from its competitors.

Firstly, the paramount consideration for any professional is sharpness and edge retention. A kanetsugu knife, especially those crafted from advanced steels like ZDP-189 or high-quality VG-10, offers a keen, long-lasting edge that drastically reduces the need for frequent sharpening during busy shifts. This efficiency is invaluable in a fast-paced kitchen environment, allowing chefs to maintain consistent performance without interruptions. The precision of a kanetsugu knife ensures clean cuts, essential for both presentation and food integrity, especially for delicate ingredients.

Secondly, the superior ergonomics and balance of a kanetsugu knife are crucial for minimizing fatigue during long hours of repetitive cutting tasks. The thoughtfully designed handles, whether in traditional “wa” style or Western, conform comfortably to the hand, providing a secure grip and reducing strain on the wrist and arm. The expert balance ensures that the knife feels like a natural extension of the chef’s hand, enhancing control and making intricate work feel effortless. This focus on user comfort makes a kanetsugu knife a true partner in the kitchen, not just a tool.

Furthermore, the durability and longevity of a kanetsugu knife represent a significant return on investment for professionals. These knives are built to withstand the rigors of daily commercial kitchen use, promising years, even decades, of reliable service with proper care. This robustness means fewer replacements and a consistent, high-performing tool that chefs can depend on day in and day out. The resilience of a kanetsugu knife minimizes downtime and ensures a chef’s equipment is always up to the task, even in the most demanding environments.

The versatility of the Kanetsugu range also contributes to its widespread appeal. From general-purpose Gyutos and Santokus to specialized slicing and pairing knives, there is a kanetsugu knife designed for virtually every culinary task. This allows chefs to curate a comprehensive set of tools, all benefiting from the brand’s renowned quality and consistent performance. Whether a chef is preparing intricate sushi, butchering primal cuts, or finely dicing vegetables, a kanetsugu knife offers a specialized yet reliable solution.

Finally, the reputation of Kanetsugu, steeped in centuries of Japanese blade-making heritage, instills a profound sense of trust and pride in ownership. Chefs recognize that when they choose a kanetsugu knife, they are not just buying a product but investing in a legacy of uncompromising quality and artistry. This intangible value, combined with the tangible benefits of exceptional performance, solidifies the kanetsugu knife‘s position as a professional’s enduring choice, standing as a testament to the pursuit of culinary perfection.

Explore More: Elevate Your Culinary Skills with Japanese Knives World

Deepen your understanding and enhance your kitchen prowess by exploring more articles on Japanese knives and culinary techniques: