In the demanding world of professional culinary arts, precision, durability, and a deep understanding of tools are paramount. Among the vast array of specialized implements, japanese butcher knives stand out as indispensable assets. These blades are not merely cutting instruments; they embody centuries of metallurgical mastery and ergonomic design, making them the preferred choice for chefs and butchers who demand unparalleled performance. From breaking down large fish to meticulously deboning poultry, the unique characteristics of these knives provide a distinct advantage.

Setting the Stage for Japanese Butcher Knives

The Philosophy and Precision Behind Japanese Blades

The philosophy underpinning japanese butcher knives is rooted in an artisanal tradition that values harmony between the maker, the material, and the user. Each blade is a testament to meticulous craftsmanship, where every forging, grinding, and sharpening step is performed with an unwavering commitment to perfection. This dedication results in knives that are not only exceptionally sharp but also incredibly balanced and agile, allowing for extended periods of use without fatigue. The emphasis on precision is evident in the razor-sharp edges and intricate geometries that define these tools.

Unlike mass-produced counterparts, many japanese butcher knives are still handcrafted by master smiths, often passing down techniques through generations. This heritage ensures that traditional knowledge, combined with modern metallurgical advancements, continues to produce blades of superior quality. The attention to detail extends beyond the blade itself, encompassing the handle, the tang, and the overall fit and finish, creating tools that are both functional and aesthetically pleasing. This holistic approach ensures that every aspect contributes to the knife’s overall performance and longevity.

Why Japanese Butcher Knives Are Essential for Culinary Professionals

For culinary professionals, the choice of tools directly impacts efficiency, safety, and the quality of their work. Japanese butcher knives offer an unmatched level of precision that is crucial for intricate butchering tasks. Their thinner blades and acute edge angles allow for cleaner cuts, minimal waste, and superior portion control, which translates into better yields and presentation in a professional kitchen. The ability to make precise, effortless cuts reduces the physical strain on the user, enhancing productivity during long shifts.

Furthermore, the exceptional sharpness and edge retention of these knives mean less frequent sharpening, maintaining peak performance throughout demanding shifts. This reliability is vital in a fast-paced environment where time is of the essence. Chefs and butchers who invest in high-quality japanese butcher knives recognize that these are not just expenses, but strategic investments in their craft and career. They enable a higher standard of culinary execution, making them truly indispensable for anyone serious about professional butchery.

The Core Arsenal: Types of Japanese Butcher Knives

Deba: The Heavyweight for Breaking Down Fish and Meat

The Deba is arguably the most recognizable and essential of all japanese butcher knives, specifically designed for heavy-duty tasks in fish and meat preparation. Characterized by its thick spine and single-bevel edge, the Deba possesses significant weight and strength, making it ideal for cutting through bones, cartilage, and fish heads. Its robust construction allows it to withstand considerable force, providing the leverage needed for demanding tasks without damaging the blade. The heel of the Deba is particularly thick and robust, serving as the primary point of contact for tougher cuts.

While powerful, the Deba is also surprisingly versatile. Its acutely sharp edge, despite the blade’s heft, enables precise filleting and portioning of fish once the initial breaking down is complete. There are various sizes of Deba, from small ko-Deba for smaller fish to larger hon-Deba designed for substantial catches. Mastering the Deba requires understanding its unique balance and the specific techniques for leveraging its weight, but once proficient, it becomes an indispensable tool for any professional dealing with whole fish or poultry. For more insights on this powerful blade, explore our Deba Knives category.

Honesuki: Mastering Poultry Deboning with Precision

The Honesuki is a specialized member of the japanese butcher knives family, designed with the specific task of deboning poultry in mind. It typically features a relatively thin, stiff blade with a triangular profile and a sharp point, allowing it to navigate around bones and joints with exceptional accuracy. While some Honesuki are single-bevel, many professional models are asymmetrical double-bevel, offering a blend of strength and precision crucial for intricate deboning work. Its robust tip is perfect for piercing joints and separating meat from bone cleanly.

Unlike Western boning knives that often have flexible blades, the Honesuki’s rigid design provides greater control and allows for cleaner cuts, reducing meat waste. Its compact size and maneuverability make it agile in tight spaces, enabling chefs to efficiently break down chickens, ducks, and other fowl with speed and minimal effort. The pointed tip is particularly useful for separating tendons and ligaments, while the straight edge near the heel can be used for initial cuts. This knife embodies efficiency and precision for poultry preparation.

Sujihiki: The Long Slicer for Immaculate Meat Cuts

The Sujihiki, often referred to as a Japanese slicing knife, is an indispensable tool among japanese butcher knives for its ability to produce long, clean, and effortless slices of cooked or raw meat. Characterized by its long, slender, and often double-bevel blade, the Sujihiki minimizes friction, allowing it to glide through roasts, briskets, and fish fillets with unparalleled ease. Its length ensures that a single, continuous cut can be made, preventing jagged edges and tearing often seen with shorter blades. This leads to perfectly presented portions every time.

The thinness of the Sujihiki’s blade is critical to its performance, as it creates less resistance when passing through protein, preserving the texture and juices of the meat. While not a boning knife, it excels at trimming silver skin, fat, and portioning large cuts into steaks or individual servings. For those demanding perfectly uniform slices and impeccable presentation, the Sujihiki is a non-negotiable tool in their collection of japanese butcher knives. It reflects the Japanese culinary emphasis on precision and aesthetic appeal in food preparation.

Gyuto and Hankotsu: Versatile Tools in the Butcher’s Repertoire

While not strictly “butcher” knives in the specialized sense like the Deba or Honesuki, the Gyuto and Hankotsu are highly versatile and often found in a professional butcher’s kit due to their adaptability. The Gyuto, the Japanese equivalent of a Western chef’s knife, is a multi-purpose workhorse capable of handling a wide range of tasks from slicing and dicing to some light butchering. Its broad blade and slight curve allow for rock chopping and precise slicing, making it a reliable choice when specialized knives are not immediately needed. Many professionals consider the Gyuto an excellent all-rounder among japanese butcher knives, especially for lighter breakdown tasks.

The Hankotsu, on the other hand, is a dedicated boning knife with a distinctive, often single-bevel, straight blade designed for separating meat from bone. Unlike the Honesuki which excels in poultry, the Hankotsu is typically used for red meat, providing the rigidity and edge retention necessary for tougher tasks. Its stout, short blade makes it agile enough for intricate work around joints and bones in larger carcasses. Together, the Gyuto and Hankotsu provide a formidable duo for a wide spectrum of butchering needs, from initial breakdown to precise trimming, highlighting the versatility inherent in Japanese knife craftsmanship.

Craftsmanship & Anatomy: What Makes Japanese Butcher Knives Unique

The Art of Steel: High Carbon vs. Stainless and Damascus Patterns

The soul of any knife lies in its steel, and japanese butcher knives are renowned for the exceptional quality and variety of metals used in their construction. Traditionally, Japanese knives were forged from high-carbon steel, such as Shirogami (White Steel) and Aogami (Blue Steel). These steels are prized for their ability to achieve incredibly sharp edges and their excellent edge retention. However, they are reactive and require diligent care to prevent rust and discoloration. The intense hardness achievable with these steels allows for a finer, more durable edge, making them a top choice for professionals.

In recent decades, stainless steels have become increasingly popular, offering greater corrosion resistance and lower maintenance, without significantly compromising sharpness in high-quality alloys. VG-10, AUS-8, and SG2 (R2) are common stainless steels found in modern japanese butcher knives, providing a balance of performance and practicality. Furthermore, many premium Japanese knives feature stunning Damascus patterns, created by folding and forging layers of different steels. This not only enhances the blade’s aesthetic appeal but can also contribute to its strength and resistance to sticking, embodying both beauty and brawn. Brands like Miyabi are renowned for their exquisite Damascus patterns and superior steel.

Edge Geometry: The Distinct Advantages of Single and Double Bevel Blades

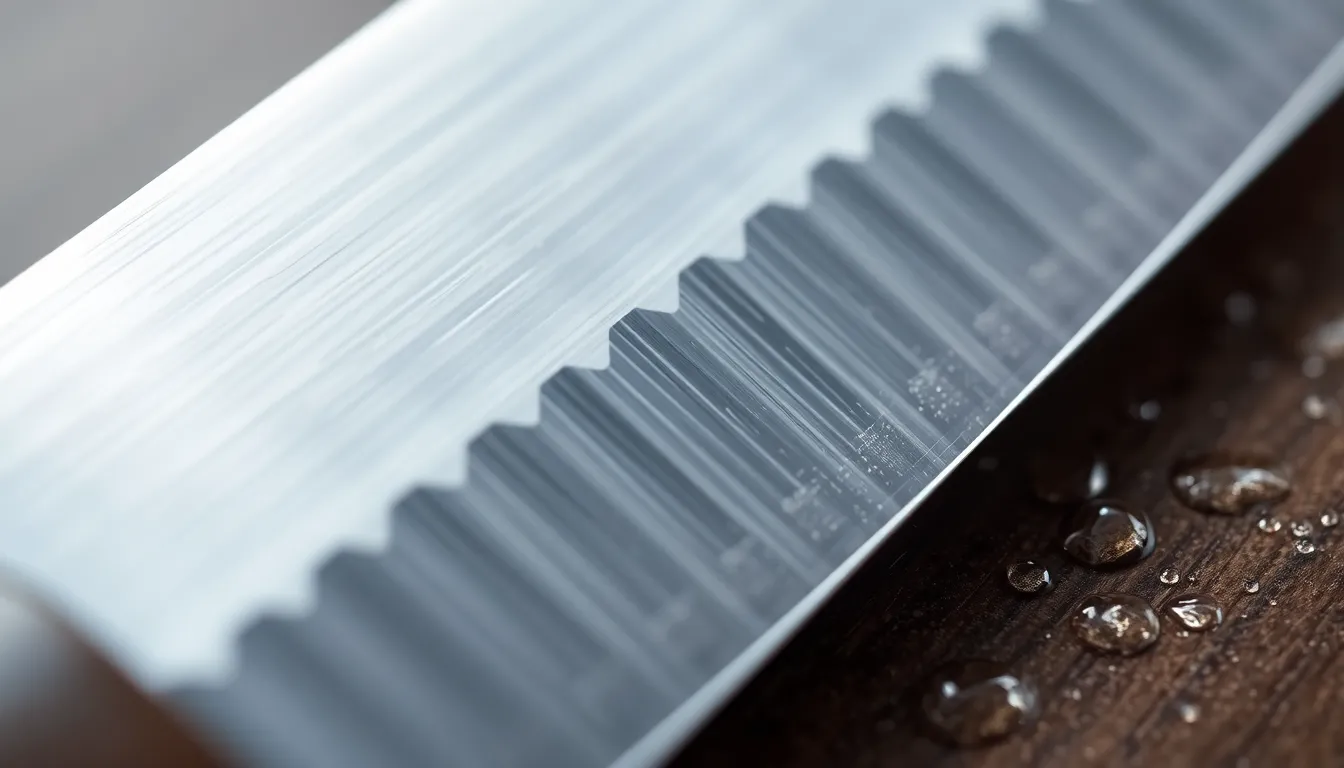

The edge geometry is perhaps the most defining characteristic distinguishing japanese butcher knives from their Western counterparts. Many traditional Japanese knives, particularly those for fish preparation like the Deba and Yanagiba, feature a single-bevel (kataba) edge. This design means the blade is sharpened primarily on one side, with the opposite side being concave or flat (urask). This unique geometry allows for an incredibly acute and precise edge, enabling extremely thin, clean cuts, especially beneficial for slicing through delicate proteins without tearing.

The single bevel creates a chisel-like edge that excels at specific tasks, such as filleting fish or making precise decorative cuts, by reducing friction and preventing sticking. Conversely, many versatile japanese butcher knives, like the Gyuto and Sujihiki, often employ a double-bevel (ryoba) edge, similar to Western knives but typically with much narrower edge angles (often 15 degrees per side or less). This symmetrical grind offers versatility for a wider range of tasks and is easier for many users to adapt to, while still maintaining the superior sharpness that Japanese knives are known for. The choice between single and double bevel depends entirely on the knife’s intended primary use and the user’s preference and skill.

Ergonomics and Balance: Wa-Handle Versus Yo-Handle Design

The handle of a knife is just as important as the blade in determining its usability and comfort, particularly during prolonged professional use. Japanese butcher knives predominantly feature two main handle styles: Wa-handles and Yo-handles. Wa-handles are traditional Japanese handles, typically made from wood (magnolia, rosewood, ebony) and come in various shapes like octagonal, D-shaped, or oval. They are lighter than their Western counterparts and are often designed for a pinch grip, offering excellent control and balance when performing intricate tasks. The lighter weight of the Wa-handle shifts the knife’s balance point forward, enhancing the cutting action and reducing wrist fatigue.

Yo-handles, on the other hand, are Western-style handles, often made from synthetic materials, composite woods, or stainless steel, and are riveted to a full tang. They are generally heavier and designed for a more palm-filling grip, offering robustness and familiar ergonomics to those accustomed to Western knives. While the choice between Wa and Yo handles for japanese butcher knives is largely a matter of personal preference and comfort, both styles are meticulously crafted to ensure optimal balance with the blade, contributing significantly to the knife’s overall performance and user experience. Understanding your preferred grip and the tasks at hand will guide your choice.

The Unseen Factors: Grind, Spine Thickness, and Fit and Finish

Beyond the obvious characteristics of steel type and edge geometry, several “unseen” factors play a crucial role in the performance and quality of japanese butcher knives. The grind of a blade refers to the cross-sectional shape of the blade itself, tapering from the spine to the edge. Japanese knives often feature sophisticated grinds, such as the convex (hamaguri) grind, which offers strength and reduces sticking, or various asymmetrical grinds that facilitate specific cutting actions. A well-executed grind ensures minimal friction and effortless cutting, making a significant difference in how the knife glides through food.

Spine thickness, while seemingly minor, also impacts the knife’s stiffness, weight, and suitability for heavy-duty tasks. A thicker spine on a Deba, for instance, provides the necessary strength for bone work, while a thinner spine on a Sujihiki allows for effortless slicing. Finally, the “fit and finish” encompasses the overall quality of construction, including how well the blade is integrated into the handle, the smoothness of the spine and choil (the unsharpened heel of the blade), and the precision of the sharpening. These details speak volumes about the craftsmanship and dedication of the maker, contributing to the knife’s durability, comfort, and safety. A superior fit and finish makes a knife feel like an extension of the hand, elevating the experience of using japanese butcher knives.

Mastering the Art: Application and Advanced Technique with Japanese Butcher Knives

Step-by-Step: Breaking Down Whole Fish with a Deba

Breaking down a whole fish is a cornerstone skill for any professional chef, and the Deba is the ultimate tool for this task. The process begins by scaling and gutting the fish. With the Deba, place the fish on a stable cutting board. First, use the robust heel of the Deba to sever the head, applying controlled pressure. Next, gently use the tip to score along the dorsal and ventral fins, guiding the initial cuts for filleting. Then, employing the full length of the blade, especially its strong spine, slice along the backbone from head to tail, separating the fillet from the bone. This requires a smooth, confident stroke, leveraging the Deba’s weight to make clean passes. Repeat for the other side.

Once filleted, the Deba’s fine edge can be used for more delicate tasks such as removing pin bones or skinning, although some prefer a Yanagiba or Sujihiki for the latter. The precision of the single-bevel Deba allows for minimal meat loss and pristine fillets, making it indispensable for preparing sashimi-grade fish. Mastering the Deba not only enhances efficiency but also elevates the quality of your fish preparations, showcasing the true power of japanese butcher knives in action.

Efficient Deboning: Practical Uses for a Honesuki in Poultry Prep

The Honesuki excels at the precise and efficient deboning of poultry, from whole chickens to ducks and turkeys. Begin by spatchcocking the bird, if desired, to expose the bone structure. The Honesuki’s sharp, pointed tip is perfect for piercing the skin and muscle around joints, such as the hip and shoulder. Use a controlled, rotating motion to separate the joint, then push the blade along the bone, keeping it as close to the bone as possible to maximize meat yield. Its rigid blade provides the necessary leverage and control to cut through connective tissue and cartilage cleanly.

For breast meat, run the Honesuki along the keel bone, using the tip to scrape meat away from the rib cage. The triangular profile of the blade allows it to navigate tight spaces and awkward angles with ease. Compared to more flexible Western boning knives, the Honesuki’s stiffness gives you superior control, preventing the blade from flexing into the meat and leaving bone fragments. Practicing these techniques with your Honesuki will significantly reduce preparation time and yield perfectly deboned poultry, a testament to the specialized design of japanese butcher knives for specific tasks.

Perfect Slicing: Techniques for Sujihiki on Large Cuts of Meat

The Sujihiki is the undisputed champion for precise slicing of large cuts of meat, whether raw roasts, cooked briskets, or delicate charcuterie. The key to maximizing its performance lies in the slicing technique. Always ensure the meat is properly chilled and rested before slicing, as this helps maintain its structure. Use long, fluid, single strokes across the entire length of the blade, from heel to tip, allowing the knife’s inherent sharpness and thinness to do the work. Avoid sawing motions, as this can tear the meat fibers and create an uneven cut. The goal is to minimize friction and resistance.

For large roasts, angle the Sujihiki slightly, allowing the weight of the blade to guide your hand. The thinness of the blade ensures that slices are uniform in thickness, which is crucial for even cooking and presentation. When slicing delicate fish fillets, the same principles apply: a single, smooth pull through the flesh will yield pristine, intact pieces. The length of the Sujihiki prevents the need for multiple passes, preserving the meat’s integrity and aesthetic. Mastering the Sujihiki transforms slicing from a chore into an art form, highlighting the elegance and efficiency of professional japanese butcher knives.

Adapting Your Gyuto for Specific Butchering Challenges

While specialist knives like the Deba and Honesuki are ideal for dedicated butchering tasks, the versatile Gyuto can be adapted for various lighter butchering challenges, especially when a dedicated tool isn’t at hand or for smaller cuts. For light deboning, use the Gyuto’s tip to navigate around smaller bones in poultry or fish, leveraging its sharpness to make clean cuts. Its robust heel can handle light chopping through smaller ribs or cartilage, though it’s crucial to avoid excessive force to prevent damage to the thinner blade. For more information on general use, visit our Gyuto Knives page.

When breaking down smaller game or processing cuts of meat, the Gyuto’s broad blade provides ample surface for scooping and transferring ingredients. Its rock-chopping motion is excellent for mincing fat or preparing smaller portions of meat for ground products. While it shouldn’t replace a true butcher knife for heavy-duty tasks, understanding the Gyuto’s capabilities allows professionals to adapt and overcome various culinary challenges with efficiency. Its balanced design and sharp edge make it a surprisingly capable companion in the butcher’s repertoire, showcasing the inherent versatility often found in well-made japanese butcher knives.

Beyond the Blade: Essential Accessories for Japanese Butcher Knives

The Imperative of Proper Sharpening Stones: Whetstone Selection and Grits

The sharpness of japanese butcher knives is legendary, but this edge can only be maintained with proper sharpening. Whetstones (or waterstones) are indispensable for this task, offering a superior edge compared to steel honing rods. Whetstones come in various grit levels, each serving a specific purpose. Coarse grits (e.g., 200-800) are used for repairing chips, reshaping an edge, or initially dull knives. Medium grits (e.g., 1000-3000) are the workhorse stones for daily sharpening, refining the edge and preparing it for polishing. Fine grits (e.g., 4000-8000+) are used for polishing the edge to a mirror finish, creating the razor-sharpness that Japanese knives are famous for. Ultra-fine grits (10,000+) are for truly extreme polishing.

Selecting the right sequence of whetstones is crucial for achieving and maintaining a consistently sharp edge on your japanese butcher knives. Professionals typically have a set of at least three stones: a medium grit for regular maintenance, a coarse grit for repairs, and a fine grit for finishing. Understanding the proper angle and technique is vital, as Japanese knives often have more acute angles than Western knives, particularly single-bevel blades. Investing time in learning proper sharpening techniques on whetstones is just as important as investing in the knives themselves, ensuring their longevity and peak performance. For a comprehensive guide, check our Knife Sharpening section.

Cutting Board Materials: Optimizing for Blade Longevity and Hygiene

The choice of cutting board material directly impacts the longevity and performance of your japanese butcher knives. Harder surfaces, such as glass, ceramic, or marble, are highly detrimental to knife edges, causing them to dull rapidly and even chip. These materials offer no give, forcing the knife’s edge to absorb all the impact, which quickly degrades sharpness. Soft, forgiving materials are paramount for preserving the delicate edges of Japanese knives. Wood, particularly end-grain wood, is an excellent choice. Its natural elasticity allows the knife edge to sink slightly into the surface, protecting it from undue stress while also being self-healing to some extent.

High-quality plastic or composite cutting boards (like those made from Hasegawa or Asahi materials) are also excellent options for professional use. These materials are durable, easy to sanitize, and kind to knife edges. They often feature a non-porous surface that resists bacterial growth, making them highly hygienic. Prioritizing soft, forgiving cutting surfaces is a non-negotiable step in caring for your japanese butcher knives. It extends the time between sharpenings and significantly prolongs the life of your valuable blades, ensuring they remain razor-sharp for years to come. Always ensure your cutting board is stable and doesn’t slip during use.

Secure Storage Solutions: Protecting Your Investment in Japanese Knives

Proper storage is essential for protecting the delicate edges and pristine finishes of japanese butcher knives. Tossing them into a drawer with other utensils is a recipe for disaster, leading to chipped edges, scratched blades, and potential rust. Magnetic knife strips are a popular and convenient storage solution, keeping knives visible and easily accessible while preventing blade-to-blade contact. Ensure the strip is mounted securely and that the blade makes contact gently to avoid dulling.

Knife blocks are another common option, provided the slots are clean and allow for easy insertion and removal without scraping the blade. Universal knife blocks with flexible inserts are often preferred, as they accommodate various blade shapes without specific slots. For portability, knife rolls or cases are indispensable for chefs who travel or transport their japanese butcher knives to different kitchens. These provide individual pockets or sleeves for each knife, protecting them from impact and environmental damage. Regardless of the chosen method, the goal is always to prevent contact between blades and other hard surfaces, keeping your investment safe and sharp.

Other Ancillary Tools: Honing Rods and Polishing Compounds

While whetstones are primary for sharpening, other ancillary tools play supporting roles in maintaining japanese butcher knives. Ceramic honing rods, softer than traditional steel rods, can be used for daily realigning of the edge between sharpening sessions. They remove tiny burrs and straighten the micro-edge that can roll over with use, restoring some of the knife’s sharpness. However, it’s crucial to use them gently and sparingly, as excessive use or improper technique can chip the delicate edge of a Japanese knife. Unlike steel rods that abrade the edge, ceramic rods mostly realign it.

Polishing compounds, often used with leather strops, are another valuable accessory. After sharpening on fine grit whetstones, stropping with a compound removes any remaining burr and polishes the edge to an even higher degree of sharpness and mirror finish. This ultra-fine polishing enhances the knife’s cutting ability and edge retention. For high-carbon steel japanese butcher knives, camellia oil or mineral oil should be used after cleaning and drying to prevent rust. Applying a thin coat creates a protective barrier, especially vital for reactive steels. These small additions to your knife care routine can significantly impact the long-term performance and beauty of your Japanese blades.

Preserving Perfection: Maintenance, Care, and Longevity of Japanese Butcher Knives

Cleaning Protocols: Preventing Rust and Maintaining Blade Integrity

Proper cleaning is paramount for preserving the integrity and performance of japanese butcher knives, especially those made from high-carbon steel. After each use, immediately wipe the blade clean with a damp cloth to remove any food residue. Never leave food acids on the blade, as they can cause discoloration and pitting, especially with reactive steels. Hand washing with mild soap and warm water is the only acceptable method; dishwashers are strictly forbidden. The harsh detergents, high heat, and aggressive spraying in a dishwasher can cause irreparable damage to the blade, handle, and overall structure of the knife.

After washing, thoroughly dry the knife immediately using a soft, clean towel. Water, even in small amounts, can lead to rust spots, particularly on high-carbon steel. For carbon steel knives, it’s advisable to apply a thin coat of food-grade mineral oil or camellia oil after drying, creating a protective barrier against moisture and oxidation. This simple cleaning protocol, performed consistently, will prevent rust, maintain the blade’s aesthetic, and significantly extend the life of your valuable japanese butcher knives. It’s a small effort for a significant return on your investment.

Sharpening Techniques: Keeping a Razor Edge on Your Japanese Blades

Maintaining the razor-sharp edge of japanese butcher knives requires consistent and proper sharpening techniques using whetstones. The fundamental principle involves maintaining a consistent angle against the stone throughout the sharpening process. For most double-bevel Japanese knives, this angle is typically between 10-15 degrees per side, significantly more acute than Western knives. Single-bevel knives require a different approach, focusing sharpening primarily on the primary bevel side, with a slight polish on the ura (hollow ground back) to remove the burr.

Begin with a medium grit stone (e.g., 1000-2000 grit) soaked in water. Place the blade on the stone at the correct angle, applying gentle, consistent pressure. Use alternating strokes, pushing into the edge and then pulling away, ensuring even coverage from heel to tip. The goal is to raise a burr (a tiny curl of metal) along the entire opposite edge. Once a burr is formed, move to a finer grit stone (e.g., 4000-6000 grit) to refine and polish the edge, gradually removing the burr. Finish with an ultra-fine stone or a leather strop for a hair-splitting edge. Consistent practice is key to mastering these techniques and truly unlocking the potential of your japanese butcher knives. For advanced tips, refer to our Knife Sharpening guide.

Common Mistakes and Troubleshooting for Japanese Knives

Even with the best intentions, users of japanese butcher knives can make common mistakes that compromise their performance or longevity. One of the most frequent errors is using the knife for tasks it’s not designed for, such as prying, twisting, or cutting through frozen foods or very hard bones (unless using a very robust Deba specifically for the task). This can lead to chipping or bending of the delicate edge. Another mistake is improper cleaning and drying, particularly leaving high-carbon knives wet, which inevitably results in rust. Dishwashers are an absolute no-go; their harsh environment is detrimental to both blade and handle.

Incorrect sharpening angles or insufficient burr removal are common sharpening pitfalls, leading to a dull or inconsistent edge. Using a steel honing rod too aggressively can also damage the fine edge of a Japanese blade. Troubleshooting often involves identifying the source of the issue: if a knife won’t hold an edge, it might be due to an incorrect sharpening angle or a poor cutting surface. If rust appears, immediate cleaning and oiling are necessary, and superficial rust can often be removed with a rust eraser or fine abrasive paste. Understanding these common issues helps in proactive care and ensures your japanese butcher knives remain in top condition.

Long-Term Care and Restoration for Professional Use

For professional chefs, japanese butcher knives are serious investments that require comprehensive long-term care and, occasionally, restoration. Beyond daily cleaning and regular sharpening, periodic professional sharpening by a skilled sharpener or a very experienced user can rejuvenate a blade that has seen heavy use or suffered minor damage. They can re-establish proper geometry and address more significant chips or dullness. Regularly checking the handle for looseness or cracks is also crucial, as a wobbly handle compromises safety and performance. Wa-handles may need occasional re-sealing or oiling to prevent drying and cracking, while Yo-handles should be checked for rivet integrity.

For high-carbon steel knives that develop a natural patina (a blue-gray discoloration that protects against rust), understand that this is desirable. However, if red rust appears, it must be addressed immediately to prevent pitting. Specialized rust removers or fine sandpaper (e.g., 2000 grit) can be used carefully to remove isolated spots. Storing knives correctly in a way that protects their edges and keeps them dry is critical for long-term preservation. A professional often has multiple japanese butcher knives, rotating them to spread wear and tear, ensuring that each tool remains in peak condition for the precise tasks it’s designed to perform throughout a long and demanding career.

The Professional’s Edge: Selecting and Investing in Japanese Butcher Knives

Identifying Quality: What to Look for in a High-Performance Blade

When selecting high-performance japanese butcher knives, several key indicators signal quality. Firstly, the steel type is paramount. Look for renowned steels like Aogami Super, Shirogami #1/2, SG2 (R2), or VG-10, known for their edge retention, sharpness, and durability. The method of construction, whether hand-forged (Honyaki or Kasumi) or machine-made, influences price and performance. Hand-forged knives, though more expensive, often offer superior edge characteristics and longevity due to the artisanal process. Examine the blade’s finish: a smooth, consistent grind and a straight, even edge are hallmarks of a well-made knife.

The fit and finish of the handle and bolster (if present) are also crucial. There should be no gaps where the blade meets the handle, as these can trap food and moisture, leading to hygiene issues or corrosion. The balance of the knife, when held, should feel natural and effortless, neither too blade-heavy nor handle-heavy for its intended purpose. Finally, reputable sellers and clear information about the knife’s origin and materials are strong indicators of quality. Investing time in researching and understanding these factors will ensure you select japanese butcher knives that are truly professional-grade and meet your exacting standards.

Navigating Brands: Reputable Makers and Artisan Options for Japanese Butcher Knives

The world of japanese butcher knives is rich with reputable brands and skilled artisan makers, each offering unique qualities. Established manufacturers like Shun Cutlery and Tojiro are widely recognized for their consistent quality, excellent heat treatment, and a broad range of models accessible to professionals. Shun, for example, is famous for its VG-10 and SG2 steel blades, often featuring beautiful Damascus patterns, and provides an excellent entry point into high-performance Japanese knives. Shun Cutlery is a prime example of a brand that combines traditional craftsmanship with modern technology to produce exceptional tools.

Beyond these larger brands, a vast number of smaller, often family-run, artisan blacksmiths (e.g., Kurosaki, Tanaka, Sakai Takayuki) produce truly exceptional, often hand-forged, japanese butcher knives. These blades are characterized by their unique aesthetics, extraordinary edge performance, and the personal touch of the maker. While they may be harder to find and often command higher prices, they represent the pinnacle of Japanese knife-making artistry. Researching these makers and understanding their specialties can lead to acquiring a truly unique and high-performing tool. When choosing, consider your budget, preferred steel, handle style, and the specific tasks the knife will be used for, then align these with the offerings of reputable brands or artisans.

Cost vs. Value: Building a Butcher’s Knife Collection That Lasts

Investing in japanese butcher knives is a significant decision for a professional, and understanding the balance between cost and value is crucial for building a lasting collection. While high-end artisan knives can be very expensive, their superior materials, meticulous craftsmanship, and exceptional performance often translate into greater longevity and reduced long-term costs. A well-cared-for Japanese knife can last for decades, outperforming and outlasting many cheaper alternatives, thereby justifying its initial price. Value isn’t just about the upfront cost; it’s about durability, performance, and the time saved through increased efficiency.

Instead of acquiring many mediocre knives, it’s often more beneficial to build a core collection of fewer, higher-quality japanese butcher knives that excel at their specific tasks. Start with the most essential tools for your daily work (e.g., a Deba for fish, a Honesuki for poultry, or a versatile Gyuto) and gradually expand as your needs evolve and budget allows. Consider the total cost of ownership, including sharpening and maintenance, when evaluating value. A truly valuable knife is one that consistently performs at a high level, enhances your skill, and inspires confidence in your work, proving to be a wise investment over your culinary career.

Comparative Analysis: Japanese Versus Western Butchery Knife Philosophies

A comparative analysis between Japanese and Western butchery knife philosophies reveals distinct approaches rooted in cultural culinary traditions. Western butcher knives often feature softer, thicker steels that are more forgiving of abuse, designed for brute force and speed, with a focus on durability over ultimate sharpness. Their edges are typically more obtuse (20-25 degrees per side), requiring less frequent but more aggressive sharpening with steel rods. Western knives tend to be heavier and designed for rock-chopping motions, reflecting a philosophy of power and robustness. For general information on different knives, explore Knife Types & Styles.

Conversely, japanese butcher knives embody a philosophy of precision, finesse, and razor-sharpness. They utilize harder, thinner steels capable of holding incredibly acute edges (10-15 degrees per side, or even single bevels). This allows for exceptionally clean, effortless cuts that minimize damage to food fibers, crucial for delicate preparations like sashimi. While requiring more careful handling and specific sharpening techniques (whetstones), the superior edge performance of Japanese knives translates to greater efficiency, less waste, and higher quality finished products. The choice between them often comes down to the specific tasks, personal technique, and the desired outcome, though many professionals now integrate both into their toolkit to leverage the strengths of each philosophy.

The Enduring Legacy of Japanese Butcher Knives

A Synthesis of Precision, Artistry, and Unmatched Performance

The enduring legacy of japanese butcher knives is a compelling synthesis of precision, artistry, and unmatched performance. These blades are more than just tools; they are a culmination of centuries of metallurgical knowledge, passed down through generations of master blacksmiths. The meticulous attention to detail, from the choice of high-quality steels to the intricate process of forging, grinding, and sharpening, results in knives that are not only extraordinarily sharp but also incredibly balanced and beautiful. This artistic commitment to perfection elevates the mundane act of butchery into a refined craft.

The unique edge geometries, whether single or double bevel, enable a level of cutting precision that is unparalleled, allowing chefs and butchers to perform intricate tasks with minimal effort and maximum yield. This precision translates directly into superior food preparation, enhancing both the aesthetic and sensory qualities of the final dish. The professional who wields japanese butcher knives embraces a tradition of excellence, valuing the harmony between human skill and exceptional tools, thereby contributing to the perpetuation of this remarkable culinary heritage.

Embracing the Future of Butchery with Superior Japanese Blades

As the culinary world continues to evolve, embracing the future of butchery means integrating the best tools available, and japanese butcher knives undoubtedly lead this charge. Their continuous innovation in steel technology and ergonomic design ensures they remain at the forefront of professional culinary equipment. By prioritizing superior sharpness, precision, and ease of use, these knives empower chefs and butchers to achieve higher standards of efficiency and artistry in their work. The emphasis on minimal waste and clean cuts aligns perfectly with modern culinary trends focused on sustainability and quality.

For any professional seeking to elevate their craft, investing in and mastering japanese butcher knives is not merely an upgrade; it’s a transformative step. It signifies a commitment to excellence, a respect for tradition, and an embrace of tools that can truly enhance one’s capabilities. As the demand for quality ingredients and precise preparation continues to rise, the role of these exceptional blades will only become more pronounced, cementing their place as indispensable instruments in the hands of culinary experts worldwide.

Explore more exceptional Japanese knives and culinary tools at https://japaneseknivesworld.com/. We invite you to discover our curated selections: