The culinary world is rich with specialized tools, and among the most revered are

japanese paring knives. Often misunderstood, these precision instruments are far more than just small blades for peeling; they embody centuries of Japanese blade-making tradition.

Their design philosophy prioritizes balance, edge retention, and ergonomic comfort, making them indispensable for intricate kitchen tasks. This comprehensive guide aims to peel back the layers of common misconceptions surrounding these remarkable knives. We will explore their unique characteristics, debunk persistent myths, and provide expert insights into their proper use and care. Prepare to gain a deeper appreciation for the artistry and functionality inherent in every true petty knife.

The Precision World of Japanese Paring Knives

In professional and home kitchens alike, the importance of a finely tuned knife cannot be overstated. Among the vast array of cutlery available,

japanese paring knives, often referred to as petty knives, stand out for their unparalleled precision and versatility. These compact yet powerful tools are designed for tasks requiring intricate detail and control, setting them apart from their Western counterparts.

Understanding the nuances of these blades is crucial for anyone looking to elevate their culinary skills. They represent a fusion of ancient forging techniques and modern ergonomic design, crafted to perform with exceptional agility. From delicate garnishes to precise trimming, the capabilities of a well-chosen petty knife are truly expansive.

Beyond the Basic Blade: What Defines a Petty Knife

A petty knife, derived from the French word “petite” meaning small, is the Japanese equivalent of a utility or small chef’s knife. Typically ranging from 120mm to 150mm (approximately 4.7 to 5.9 inches) in blade length, it’s designed for nimble work. Unlike a simple peeling knife, a petty knife possesses a versatile profile that allows for a wide range of kitchen tasks. Its defining characteristics include a thinner blade, often with a harder steel core, and a razor-sharp edge. These attributes contribute to its superior cutting performance and fine control. The term “petty” itself underscores its role as a smaller, more maneuverable version of a chef’s knife, capable of detail work that larger blades cannot achieve. This fundamental design sets

japanese paring knives apart in any knife roll.

The construction of a petty knife often involves sophisticated layering techniques, such as san-mai or suminagashi, which protect the ultra-hard core steel. This provides a balance of incredible sharpness and durability. The spine of the blade is typically thinner than that of a Western paring knife, allowing for less resistance when cutting. Furthermore, the grind is often asymmetrical, contributing to the knife’s exceptional cutting prowess. These subtle yet significant design choices elevate the petty knife from a mere utility tool to a precision instrument. Understanding these distinctions is key to appreciating the engineering marvel that

japanese paring knives represent, especially when considering their application in intricate culinary tasks. Their lightweight feel and agile nature make them extensions of the hand, providing unparalleled feedback during use.

Navigating the Mystique: Common Misconceptions Unveiled

Despite their growing popularity,

japanese paring knives are often shrouded in misconceptions that can deter potential users or lead to improper handling. One common myth is that they are excessively fragile due to their thin, hard blades. While they do require a different approach to care than robust Western knives, fragility is a misunderstanding rather than a fact. Another misconception is that their use is limited solely to peeling fruits and vegetables, overlooking their extensive capabilities for intricate work. This narrows their perceived utility significantly.

Many also believe that their high cost automatically equates to superior performance, without understanding the underlying craftsmanship and materials that justify the price. The nuances of Japanese steel, edge geometry, and handle design are often overlooked, leading to an oversimplified view. Debunking these myths is essential for fully appreciating and utilizing these magnificent tools. It allows cooks to approach

japanese paring knives with accurate expectations and the knowledge needed to unlock their full potential. Our goal is to demystify these blades, revealing their true nature as resilient, versatile, and expertly crafted instruments.

Furthermore, the belief that all Japanese knives are difficult to sharpen is another prevailing myth. While some traditional Japanese steels can be challenging for novices, many modern alloys are designed for easier maintenance, especially in the context of

japanese paring knives. The notion that these knives are exclusively for professional chefs also limits their accessibility to home cooks who could greatly benefit from their precision. We will delve into these and other misconceptions, providing clear, factual information to guide your understanding. By shedding light on the realities of these knives, we aim to encourage more cooks to embrace the unparalleled experience they offer.

Myth 1: All Small Knives Are Created Equal – The Petty Knife Distinction

The notion that all small knives serve the same purpose is a widespread misconception, especially when comparing Western paring knives with

japanese paring knives, specifically the petty knife. While both are compact, their design philosophies, blade geometries, and intended uses diverge significantly. A Western paring knife is primarily designed for in-hand peeling and simple trimming, characterized by a shorter, often thicker blade and a more robust tip. Its focus is on durability and ease of use for basic tasks. The petty knife, in contrast, is engineered for detailed board work and intricate cuts, offering a level of precision that its Western counterpart cannot match.

This fundamental difference in design arises from distinct culinary traditions and cutting techniques. Japanese cuisine emphasizes precision, delicate presentation, and efficient preparation, which necessitates tools tailored for such demands. Consequently, the petty knife embodies these principles, offering superior sharpness and control for tasks like mincing garlic, segmenting citrus, or even filleting small fish. Understanding this distinction is the first step in appreciating the specialized role of

japanese paring knives in a well-equipped kitchen. It highlights why one might choose a petty knife over a standard paring knife for particular tasks.

Western Paring Knives vs. Japanese Petty Knives: A Design Philosophy

The design philosophy behind Western paring knives typically prioritizes robustness and utility for general tasks. They often feature blades made from softer, more flexible stainless steels, designed to withstand a degree of abuse and be easily resharpened with minimal effort. Their blade profiles are usually thicker at the spine, tapering to a utilitarian edge that holds up well against harder surfaces or less delicate cutting techniques. The handles are often full-tang, providing a heavy, secure grip, suitable for peeling vegetables held in hand. This design reflects a heritage of general-purpose kitchen tools built for endurance. For a broader look at different knife types, check out our guide on knife buying guides.

Conversely,

japanese paring knives, or petty knives, are conceived with precision, sharpness, and finesse as their core tenets. They feature thinner blades, often crafted from harder, high-carbon steels that allow for an extremely acute edge angle. This results in a knife that glides through ingredients with minimal resistance. The emphasis is on elegant cuts, intricate detail work, and superior edge retention, which means less frequent sharpening during use. Their handles, whether traditional Wa-style or Western-style, are meticulously balanced to promote control and reduce hand fatigue. This philosophical divergence leads to two distinct tools, each excelling in its own domain. The subtle differences in the blade profile of a petty knife are what allow it to perform with such exceptional grace and precision.

The choice between a Western paring knife and a Japanese petty knife ultimately depends on the specific tasks at hand and the user’s preferred cutting style. If the primary need is robust peeling and general utility, a Western paring knife serves well. However, for chefs and home cooks seeking precision, fine detail work, and an unparalleled cutting experience, the petty knife is the clear choice. It is a testament to the fact that not all small knives are indeed created equal, especially when considering the intricate design and performance characteristics of

japanese paring knives. The distinct heritage of each knife type dictates its form and function, ensuring that each is optimized for specific culinary applications. Many find that owning both offers the most versatile kitchen setup.

Blade Geometry and Profile: Understanding the Core Differences

The fundamental distinction between Western paring knives and

japanese paring knives lies deeply embedded in their blade geometry and profile. Western paring knives typically feature a thicker, more robust spine and a double-bevel edge, often ground to an angle of 20-25 degrees per side. This geometry lends itself to strength and durability, making the knife less prone to chipping even when encountering harder materials or being used for light prying. The thicker blade provides stability during the push-pull cutting motion, common in Western culinary techniques. Its more rounded profile often means less precise tip work but greater resilience.

In contrast,

japanese paring knives, or petty knives, boast a significantly thinner blade profile, often tapering to a fine point. Their edges are frequently ground to a much more acute angle, typically 10-15 degrees per side, and sometimes even single-bevel (kataba) for specialized petty knives. This acute angle, combined with harder steel, allows for incredible sharpness and minimal friction when cutting. The thinness of the blade ensures that it glides through ingredients with ease, preventing wedging and preserving the ingredient’s cellular structure. This precision is vital for delicate work like fine brunoise or intricate garnishes. The difference in blade thickness is immediately noticeable to the user, impacting the feel and performance of the knife significantly.

Furthermore, many

japanese paring knives feature a slight curvature along the edge that is ideal for push-cutting and delicate slicing on a cutting board. The tip is often exceptionally fine, enabling precise piercing and intricate detail work, such as deseeding chilies or de-veining shrimp. This meticulous attention to blade geometry transforms the petty knife into an instrument of precision, optimized for tasks that demand utmost control and clean cuts. Understanding these core differences in design illuminates why these seemingly similar small knives perform so differently in the kitchen, solidifying the petty knife’s unique position. The slight variations in the curvature of the blade can greatly affect how it performs certain tasks.

The Versatility Argument: Why Petty Knives Excel in Detail Work

While often stereotyped as merely peeling knives, the true strength of

japanese paring knives lies in their remarkable versatility for detail work. Their slender, razor-sharp blades and precise tips make them indispensable for tasks that demand finesse and accuracy. From mincing small aromatics like garlic, ginger, and shallots with incredible uniformity to meticulously segmenting citrus fruits without damaging membranes, the petty knife excels where larger knives would be cumbersome or imprecise. This agility allows chefs to perform intricate cuts quickly and cleanly. The refined control offered by a petty knife truly elevates the outcome of your food preparation, moving beyond simple utility.

Beyond simple chopping, a petty knife is perfect for intricate garnishes, creating decorative cuts in vegetables, or forming precise channels for sauces. Its fine tip is ideal for removing blemishes, coring small fruits like strawberries, or delicate de-boning tasks for small poultry or fish. This level of control minimizes waste and maximizes the visual appeal of dishes. Unlike bulkier Western paring knives, the petty knife feels like an extension of the hand, providing superior tactile feedback and maneuverability. This makes it invaluable for tasks requiring high precision. Exploring techniques for fine cutting can further enhance your appreciation for these knives; consider checking out our knife skills guide for more information.

Moreover, the balance and light weight of

japanese paring knives reduce hand fatigue during prolonged, detailed work, allowing for sustained precision. Whether you’re preparing elaborate appetizers, delicate sushi components, or simply refining the presentation of a home-cooked meal, the petty knife proves itself as an exceptionally capable and versatile tool. Its ability to transition seamlessly from one intricate task to another solidifies its reputation as an essential instrument for any serious cook. This adaptability is what truly defines the petty knife as a master of detail, moving beyond the limitations of basic paring tools. Many professional chefs consider it one of the most important knives in their collection, second only to a chef’s knife.

Myth 2: Sharper Means Better – The Nuance of Japanese Blade Steels

The idea that a knife’s quality is solely determined by how sharp it is out of the box is a pervasive myth, particularly when discussing

japanese paring knives. While Japanese knives are renowned for their exceptional sharpness, this characteristic is merely one facet of a complex interplay of steel composition, heat treatment, and blade geometry. True quality in a Japanese blade involves a nuanced balance of edge retention, ease of sharpening, toughness, and corrosion resistance. An ultra-sharp edge that dulls quickly or is prone to chipping is not necessarily “better” than a slightly less acute edge that maintains its keenness over prolonged use and is easier to restore.

The selection of steel is paramount in achieving these diverse properties. Different steels offer varying trade-offs: some are incredibly hard, allowing for extreme sharpness and edge retention, but can be more brittle. Others are tougher and more forgiving but may not hold an edge as long. Understanding these nuances is crucial for appreciating the craftsmanship behind

japanese paring knives and for selecting a blade that aligns with individual usage patterns and maintenance capabilities. It’s about finding the right balance for your specific culinary needs, rather than chasing absolute sharpness alone. The subtle differences in steel properties are what give each knife its unique character and performance.

The Alchemy of Steel: VG-10, AUS-8, White Steel, Blue Steel Explained

The heart of any exceptional knife, especially

japanese paring knives, lies in its steel. Japanese knifemakers employ a diverse range of steels, each with unique properties. VG-10 is a popular stainless steel, often used in many professional and high-end home kitchen knives. It’s known for its excellent balance of hardness (HRC 60-61), edge retention, and corrosion resistance due to its high carbon, chromium, cobalt, and molybdenum content. Knives made with VG-10 are relatively easy to maintain and sharpen, making them a great choice for everyday use. Its popularity stems from its reliable performance and durability in various kitchen environments. Many brands like Shun and Tojiro utilize VG-10 in their product lines.

AUS-8 is another common stainless steel, particularly in more affordable

japanese paring knives. It’s softer than VG-10 (HRC 57-59) but offers superior toughness and ease of sharpening. While it may not hold an edge as long as harder steels, its resilience makes it forgiving for beginners or those who prefer less delicate maintenance. It’s a workhorse steel that can withstand more abuse and is less prone to chipping. The affordability and practical characteristics of AUS-8 make it a staple in many entry-level to mid-range Japanese knife sets. It’s an excellent choice for those prioritizing durability and ease of care.

On the more traditional side, we find carbon steels like White Steel (Shirogami) and Blue Steel (Aogami). White Steel, available in different grades (e.g., Shirogami #1, #2, #3), is a pure carbon steel with very few impurities. It can be hardened to extremely high HRC levels (61-64+), allowing for an incredibly sharp and fine edge. However, it’s highly reactive and prone to rust, requiring meticulous care and developing a protective patina over time. Blue Steel, an alloy of White Steel with added chromium and tungsten, offers slightly better toughness and edge retention while still achieving exceptional sharpness (HRC 62-65+). It’s also less reactive than White Steel but still requires diligent maintenance. Both White and Blue steels are favored by traditional artisans for their unparalleled cutting performance and ability to achieve a “live” edge. Understanding these steel types is crucial for selecting the right

japanese paring knives for your specific needs and maintenance commitment. For a deeper dive into knife materials, you can explore our detailed section on blade steels.

Edge Retention vs. Ease of Sharpening: A Critical Balance for Japanese Paring Knives

When evaluating

japanese paring knives, understanding the critical balance between edge retention and ease of sharpening is paramount. These two characteristics often exist in an inverse relationship: steels that hold an incredibly sharp edge for a long time (high edge retention) are typically very hard and can be more challenging and time-consuming to sharpen. Conversely, softer steels that dull more quickly (lower edge retention) are generally much easier and faster to bring back to a keen edge. This trade-off is a fundamental consideration for both manufacturers and users.

Harder steels, like those found in high-end Japanese knives (e.g., VG-10, SG2, Aogami), allow for a very acute edge angle and maintain that sharpness through extensive use. This means fewer interruptions during long cooking sessions. However, when these edges eventually do dull, they require specialized sharpening techniques, often with water stones, and more patience to restore. The user must be committed to learning and practicing proper sharpening methods. For a comprehensive guide on sharpening, consider visiting our knife sharpening guides section.

Softer steels, like AUS-8 or some Western stainless steels, may need to be honed or sharpened more frequently. However, they are far more forgiving and can often be quickly restored with simpler tools like pull-through sharpeners or ceramic rods. This ease of maintenance makes them highly practical for busy kitchens or for users who prefer less intensive sharpening rituals. The optimal balance for

japanese paring knives depends on the individual cook’s priorities: whether they value maximum cutting performance and infrequent sharpening sessions, or a knife that’s easy to maintain even if it means slightly more frequent touch-ups. There is no universally “better” choice; only the choice that best suits the user’s skills and preferences.

Hand Forging and Cladding: The Artisanal Edge

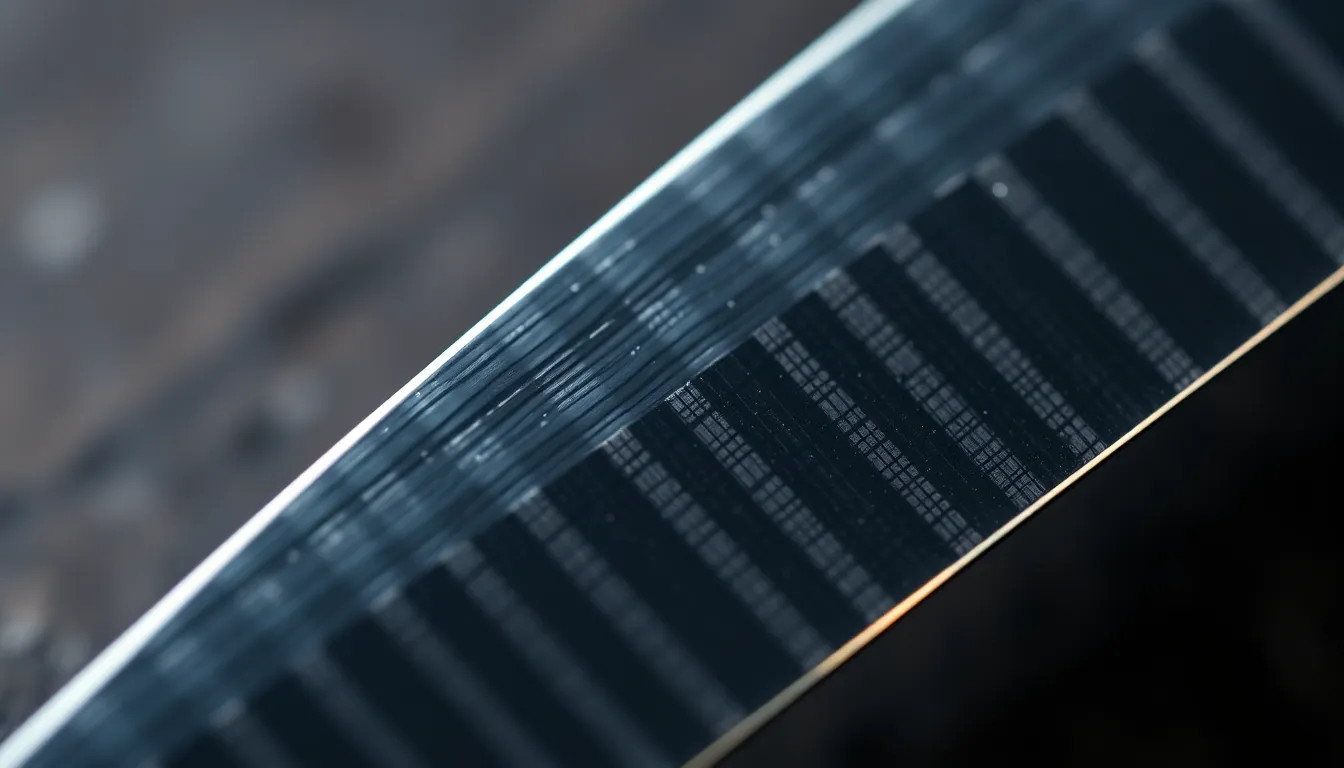

The distinction of many

japanese paring knives often extends beyond just steel type to the intricate processes of hand forging and cladding. Hand forging, known as “tanzo” in Japanese, involves repeatedly heating and hammering the steel. This process refines the grain structure of the steel, making it tougher and more resilient, while also allowing the smith to shape the blade with incredible precision. This artisanal approach is labor-intensive but results in a blade with superior performance characteristics compared to mass-produced, machine-stamped knives. The subtle variations created by the human hand give each knife a unique character. This traditional method contributes significantly to the knife’s overall balance and feel.

Cladding is another hallmark of traditional Japanese knife making. This technique involves sandwiching a core of very hard, high-carbon steel (the “hagane”) between layers of softer, more ductile stainless or iron steel (the “jigane”). This creates a composite blade, often seen in patterns like San Mai (three layers) or Damascus (multiple folded layers). The softer outer layers provide several benefits: they protect the brittle, hard core from impact and corrosion, especially if the core is a reactive carbon steel. They also make the knife easier to sharpen by providing a softer material to grind away on the sides. The striking visual patterns often seen on Damascus-clad

japanese paring knives are a beautiful byproduct of this functional layering process. These patterns not only add aesthetic appeal but also indicate the complex construction of the blade.

This combination of hand forging and cladding allows for the best of both worlds: an extremely sharp and durable edge from the hard core steel, protected and supported by resilient outer layers. It’s a testament to the meticulous craftsmanship and deep understanding of metallurgy that defines Japanese knifemaking. When you invest in

japanese paring knives created using these traditional methods, you’re not just buying a tool; you’re acquiring a piece of functional art, engineered for peak performance and longevity. The presence of a distinct forge line or beautiful Damascus pattern can often indicate such artisanal construction, signifying a higher level of craftsmanship. This level of detail sets them apart from most mass-produced knives.

Myth 3: Handle Type Doesn’t Matter – The Ergonomics of Control

One of the most overlooked aspects of knife performance, particularly with

japanese paring knives, is the handle. The myth that “handle type doesn’t matter” is fundamentally flawed. In reality, the handle is the primary point of contact between the user and the blade, directly influencing comfort, control, balance, and ultimately, precision. A poorly designed or ill-fitting handle can lead to hand fatigue, loss of grip, and a significant reduction in cutting accuracy, no matter how sharp the blade. For delicate tasks performed by a petty knife, where intricate movements are required, the ergonomics of the handle are absolutely critical.

The choice of handle material, shape, and how it balances with the blade are all meticulously considered by Japanese knifemakers. Different handle styles cater to various preferences and grip types, each offering distinct advantages. Dismissing the handle’s importance is akin to ignoring the steering wheel in a car; it’s the interface that translates the user’s intent into action. Understanding the nuances of handle design is essential for selecting

japanese paring knives that truly feel like an extension of your hand, enabling effortless control and preventing discomfort during prolonged use. A comfortable handle also reduces the risk of accidents by providing a more secure grip, enhancing overall kitchen safety. The perfect handle can make a significant difference in a chef’s daily work.

Wa-Handle vs. Western Handle: Grip, Balance, and Personal Preference

When selecting

japanese paring knives, one of the most significant choices users face is between the traditional Japanese (Wa-handle) and Western-style handles. The Wa-handle is typically lightweight and made from wood, often with a hidden tang that extends partially into the handle. It comes in various shapes, such as octagonal, D-shaped, or oval, designed to fit snugly in the hand and provide excellent grip, especially during push-cutting techniques. The D-shaped handle, for example, offers a natural index point, guiding the user’s grip. Wa-handles contribute to a blade-forward balance, which enhances the feeling of precision and lightness during delicate work.

Western handles, conversely, are typically heavier, full-tang designs made from composite materials, wood, or synthetic polymers. They are often ergonomic, molded to fit the hand, and provide a secure, comfortable grip for a wide range of tasks. These handles often contribute to a more balanced feel at the bolster, providing a sense of robustness and control, which is favored by those accustomed to Western-style cutting motions. The heavier handle can provide leverage for heavier chopping. Many

japanese paring knives, especially those designed for the export market, feature Western handles to appeal to a broader audience. Ultimately, the choice between a Wa-handle and a Western handle comes down to personal preference, grip style, and the type of balance desired. There is no objectively superior option; it’s about what feels most natural and comfortable for the individual user during various culinary tasks. Some chefs prefer the traditional aesthetic of the Wa-handle, while others opt for the familiar feel of a Western handle.

Trying out both types of handles, if possible, is highly recommended to determine which best suits your hand and cutting style. Factors like hand size, grip strength, and the specific culinary techniques you employ regularly should all influence your decision. A comfortable and secure grip is crucial for control and safety, particularly when performing intricate tasks with

japanese paring knives. The subtle differences in how a handle fits your hand can dramatically impact performance over long periods of use. The choice of handle also subtly influences the overall aesthetic and traditional feel of the knife.

The Importance of Balance Point: Precision and Fatigue Reduction

The balance point of

japanese paring knives is a critical, yet often overlooked, ergonomic feature that directly impacts precision and reduces hand fatigue. The balance point is where the knife feels perfectly weighted and pivots effortlessly in your hand. For many Japanese knives, especially those with traditional Wa-handles, the balance point is typically located slightly forward, towards the tip of the blade or at the choil (the unsharpened heel of the blade). This blade-heavy balance allows the knife to fall naturally into the cut, requiring less effort from the user and enhancing the sensation of cutting precision. It feels as if the knife is doing the work for you. This forward balance is a hallmark of many Japanese designs, promoting nimble and controlled movements.

When the balance point is optimized, the knife becomes an extension of the hand, providing superior control for intricate tasks like detailed garnishing, delicate trimming, or precise slicing. A well-balanced

japanese paring knives reduces the strain on your wrist and forearm, significantly mitigating hand fatigue during extended periods of use. Conversely, a poorly balanced knife, whether too handle-heavy or excessively blade-heavy, can feel cumbersome and awkward, requiring more muscular effort to manipulate. This can lead to discomfort, reduced accuracy, and premature fatigue, especially when performing repetitive, fine motor tasks.

For petty knives, where precision is paramount, an ideal balance point is even more crucial. It allows for subtle, controlled movements that are essential for tasks like coring a tomato, peeling a delicate fruit, or scoring a pastry. When selecting

japanese paring knives, paying attention to how the knife feels in your hand and where its balance point lies can make a profound difference in your cutting experience. It transforms a simple tool into an instrument of effortless precision, enabling you to work smarter, not harder, in the kitchen. The subtle feeling of a perfectly balanced knife is something that experienced chefs deeply appreciate, making their work more enjoyable and less tiring. This thoughtful design leads to an intuitive cutting experience.

Real-World Ergonomics: Hand Feel Across Diverse Tasks

The true test of a knife’s ergonomics, especially for

japanese paring knives, lies in its real-world application across diverse culinary tasks. A knife that feels comfortable during a quick peel might become a source of discomfort during prolonged, intricate detail work. The handle’s material, texture, and shape all contribute to how it feels in the hand. Materials like natural wood offer a warm, tactile grip that can absorb moisture, while synthetic composites provide durability and consistent texture. The contour of the handle should ideally conform to the natural curves of your hand, allowing for a secure grip without requiring excessive force. This tactile feedback is essential for maintaining control during precise cuts.

Consider tasks such as mincing herbs for an extended period, segmenting a large batch of citrus, or meticulously preparing garnishes. In these scenarios, the handle’s ability to prevent hot spots, maintain grip even when wet, and distribute pressure evenly across the hand becomes critical. A well-designed handle on

japanese paring knives will allow for various grip styles – whether it’s a pinch grip, a handle grip, or a finger-forward grip – enabling the user to adapt to different cutting needs without compromising comfort or control. The transitions between the blade and handle should be smooth, preventing any sharp edges or uncomfortable ridges that could dig into the fingers during use. This attention to detail in ergonomic design is what elevates a good petty knife to a great one. The difference in grip comfort can be the deciding factor for long-term satisfaction with a knife.

Ultimately, the “hand feel” is subjective, but its impact on performance is universal. A knife that feels like an extension of your arm, rather than a separate tool, will significantly enhance your precision, reduce fatigue, and make the culinary process more enjoyable. Therefore, when choosing

japanese paring knives, it’s highly recommended to handle them, if possible, and simulate various cutting motions to assess their ergonomic suitability for your specific needs and preferences. This hands-on assessment will reveal the true comfort and control offered by the handle across a spectrum of kitchen tasks, affirming that handle type truly does matter. The subtle variations in handle contour can greatly impact how the knife performs for different users.

Myth 4: Japanese Paring Knives Are Only for Peeling – Unlocking Their Full Potential

One of the most persistent and limiting myths about

japanese paring knives is that their utility is confined solely to peeling fruits and vegetables. This misconception drastically underestimates the true potential and versatility of the petty knife. While they certainly excel at peeling with their acute edges and precise tips, their design allows them to perform a vast array of intricate and detailed tasks that larger chef’s knives or even general utility knives cannot accomplish with the same finesse. To confine them to mere peeling is to overlook their true calling as precision instruments.

A petty knife, with its agile blade and ergonomic design, is a master of detailed board work, fine trimming, and even delicate boning of small proteins. It is the go-to tool for tasks where control, accuracy, and minimal waste are paramount. By debunking this myth, we aim to encourage home cooks and professional chefs alike to explore the full spectrum of capabilities that

japanese paring knives offer, transforming them from a simple peeling tool into an indispensable multi-tasker in the kitchen. Unlocking their full potential will undoubtedly elevate your culinary creations. The agile nature of these knives allows for incredible detail work that larger blades simply cannot provide, making them invaluable for precision tasks.

Intricate Cuts and Detail Work: From Garnishes to Filleting Small Fish

The true artistry of

japanese paring knives shines brightest in their capacity for intricate cuts and detail work. Far beyond mere peeling, these nimble blades are indispensable for tasks that demand meticulous precision. Consider the creation of delicate garnishes: paper-thin cucumber ribbons, perfectly carved radish roses, or intricate fruit designs for cocktails and desserts. The petty knife’s sharp, thin blade allows for such fine work, making clean, effortless cuts without bruising or tearing delicate ingredients. This level of detail elevates food presentation, turning simple dishes into culinary masterpieces.

Moving beyond garnishes, a petty knife is ideally suited for preparing small, delicate ingredients. It excels at mincing garlic and shallots to an incredibly fine consistency, ensuring even flavor distribution without large, harsh pieces. Its fine tip is perfect for de-seeding chilies, de-veining shrimp, or removing the core from small tomatoes and strawberries with minimal waste. For protein preparation, these

japanese paring knives prove invaluable for filleting small fish, such as sardines or anchovies, with precision, separating flesh from bone cleanly. They are also excellent for trimming silverskin from tenderloins or portioning smaller cuts of meat with accuracy. The control afforded by a petty knife makes these otherwise challenging tasks manageable and efficient.

Furthermore, for those who dabble in charcuterie or cheese boards, the petty knife is excellent for creating clean slices of cured meats or segmenting softer cheeses with finesse. Its ability to navigate tight spaces and perform controlled cuts makes it a powerhouse for tasks demanding accuracy over sheer power. Embracing the full potential of

japanese paring knives for intricate cuts transforms your culinary process, enabling you to achieve professional-level results in your own kitchen. This versatility makes it a standout tool, deserving of its place alongside larger, more common chef’s knives. Their precision is unmatched for creating stunning visual elements in your dishes.

Precision Trimming and Sectioning: Fruits, Vegetables, and Proteins

The precision inherent in

japanese paring knives makes them exceptional tools for trimming and sectioning a wide variety of ingredients. When dealing with fruits, a petty knife can effortlessly remove blemishes, cores, or stems with minimal loss of edible product. It’s superb for segmenting citrus, meticulously separating the fruit from the pith and membranes, resulting in beautiful, juicy segments perfect for salads or desserts. For stone fruits, it can help separate flesh from the pit cleanly and efficiently, minimizing waste and creating visually appealing portions. This precision reduces waste and improves the presentation of your ingredients.

For vegetables, the petty knife shines in tasks requiring detailed cleanup and portioning. It’s ideal for trimming excess fat from cuts of meat, removing sinew, or preparing poultry for specific dishes. The thin blade allows you to work close to bones or cartilage, maximizing yield while ensuring clean cuts. When working with delicate herbs, it can finely chop or chiffonade them with unparalleled accuracy. Its size and agility make it far more suitable than a large chef’s knife for tasks where careful removal of unwanted parts is necessary, such as cleaning mushrooms or shaping vegetables for specific cooking methods. The control it provides is critical for achieving professional results.

Even with larger proteins, a petty knife remains valuable for precision trimming of delicate areas or for creating specific portion sizes. Its ability to maneuver in tight spaces allows for intricate detail work that would be awkward or unsafe with a larger knife. From removing small bones from fish fillets to preparing individual servings of tenderloin,

japanese paring knives ensure clean cuts and elegant presentations. This precision trimming capability is a testament to the petty knife’s true versatility, debunking the myth that it’s only a peeling tool and establishing it as an indispensable asset for detailed food preparation. Many professional kitchens rely heavily on these knives for intricate plating and preparation. You can learn more about general knife care on our care and maintenance page.

Beyond the Board: Specialized Applications of a Petty Knife

While often associated with cutting board tasks, the utility of

japanese paring knives extends significantly beyond the flat surface, making them invaluable for a range of specialized, in-hand applications. Their compact size and razor sharpness are perfectly suited for jobs where a larger knife would be unwieldy or unsafe. Consider tasks like spiraling potatoes for deep-frying, or creating intricate decorative cuts on vegetables to elevate a presentation. The small blade allows for superior control when working with foods held in the hand, where a high degree of dexterity is required. This kind of nuanced control is difficult to achieve with larger knives, making the petty knife indispensable for these specialized uses.

For pastry and baking, a petty knife can be surprisingly useful. It’s excellent for trimming excess dough from tart molds, scoring bread loaves for a perfect crust, or creating delicate cut-outs for decorative elements. Its precision allows for clean lines and shapes without tearing. In the realm of bartending, a petty knife is ideal for cutting citrus twists, creating intricate garnishes for cocktails, or even peeling long, thin strips of zest. The ability to perform these delicate tasks with ease and accuracy makes it a favorite among mixologists. Its fine tip is also perfect for intricate tasks like segmenting small fruits for fruit salads or precise deseeding of chilies.

Even for non-culinary tasks, the agility and sharpness of

japanese paring knives can find niche applications, such as opening packages cleanly or performing delicate crafts (though it’s generally advised to keep kitchen knives solely for food). However, within the culinary sphere, its capacity for in-hand, intricate work truly sets it apart. By recognizing these specialized applications, one can fully appreciate the comprehensive utility of a petty knife, moving far beyond the simple act of peeling and embracing its role as a versatile, high-precision instrument in the kitchen. This broad range of uses solidifies its position as a go-to tool for both professional chefs and passionate home cooks seeking perfection in their culinary creations. The knife truly becomes an extension of the hand.

Myth 5: Japanese Paring Knives Are Too Delicate to Maintain – Longevity Through Proper Care

A widespread misconception is that

japanese paring knives are excessively delicate and difficult to maintain, prone to chipping or rusting at the slightest misuse. While it is true that these knives often feature harder, thinner blades and require a different approach to care than their robust Western counterparts, calling them “delicate” is an oversimplification that can deter potential users. With proper understanding and adherence to simple care protocols, Japanese paring knives are incredibly durable and capable of providing decades of exceptional service. Their longevity is a testament to their superior craftsmanship, not a fragility that needs constant worrying.

The perception of fragility often stems from improper usage, such as cutting on hard surfaces or applying excessive force sideways, rather than an inherent weakness in the knife itself. Understanding the specific characteristics of Japanese steel and blade geometry is key to proper maintenance. This section aims to demystify the care process, demonstrating that with consistent and appropriate habits, your

japanese paring knives will retain their razor-sharp edge and pristine condition for many years, proving that they are far from being too delicate. In fact, their design often allows for easier sharpening, given the right tools and technique. The key is to respect the material and its intended use.

Honing and Sharpening Techniques: Preserving the Razor Edge of Japanese Paring Knives

Preserving the renowned razor edge of

japanese paring knives requires specific honing and sharpening techniques, distinct from those used for many Western knives. Honing, which realigns a slightly rolled edge, is typically done with a ceramic or fine-grit honing rod. Unlike steel honing rods that abrade the edge, ceramic rods gently coax the microscopic burr back into alignment without removing significant material. This should be done frequently, even daily, depending on usage, to keep the edge performing optimally and delay the need for full sharpening. The goal of honing is to maintain, not to create, an edge. It’s a quick and essential step in daily knife maintenance.

When the edge eventually dulls and honing is no longer effective, sharpening becomes necessary. For Japanese knives, water stones (whetstones) are the preferred method. These stones come in various grits, from coarse (for repairing chips or significant dullness) to medium (for primary sharpening) to fine (for polishing and refining the edge). The typical sharpening process involves starting with a medium grit (e.g., 1000-2000 grit) to establish a new bevel, followed by a fine grit (e.g., 4000-6000 grit) to polish the edge and achieve incredible sharpness. Some users even progress to ultra-fine grits (8000+ or natural stones) for a mirror-polished, hair-popping edge. Maintaining a consistent angle, often 10-15 degrees per side for

japanese paring knives, is crucial for effective sharpening. The process might seem daunting at first, but with practice, it becomes a meditative and rewarding skill that ensures your knives perform at their peak. It’s an investment in the longevity and performance of your culinary tools. For more detailed instructions, consider reviewing resources on knife sharpening techniques. Remember, practice makes perfect when it comes to mastering water stone sharpening.

Unlike pull-through sharpeners or electric grinders, which can aggressively remove steel and alter blade geometry, water stones offer precise control and preserve the integrity of the delicate Japanese edge. With proper technique and regular maintenance, your

japanese paring knives will provide years of effortless cutting, dispelling any notion of them being overly delicate. Consistency in sharpening is far more important than intensity. Regular, gentle sharpening maintains the edge, preventing it from becoming too dull and requiring more aggressive methods. This proactive approach saves time and preserves the blade over its lifetime.

Cleaning and Storage Protocols: Preventing Corrosion and Damage

Proper cleaning and storage protocols are essential for preventing corrosion and damage to

japanese paring knives, ensuring their longevity and maintaining their pristine condition. Immediately after each use, the knife should be hand-washed with warm water and a mild dish soap. It is crucial to never put a Japanese knife in a dishwasher. The harsh detergents, high heat, and abrasive environment of a dishwasher can severely damage the blade, dull the edge, corrode the steel (especially carbon steel), and degrade the handle material. Hand washing is gentle and effective.

After washing, immediately dry the knife thoroughly with a clean towel. Residual moisture is the primary cause of rust and corrosion, particularly for carbon steel blades which are highly reactive. Even stainless steel

japanese paring knives can develop water spots or pitting if left wet. For carbon steel knives, some users apply a very thin layer of food-grade mineral oil after drying for added protection, especially if the knife will be stored for an extended period. This creates a barrier against moisture and air. This simple step can prevent significant long-term damage, preserving the knife’s aesthetic and functional integrity.

Storage is equally important. Avoid storing your

japanese paring knives loosely in a drawer where they can jostle against other utensils, leading to dulling, chipping, or scratching of the blade and handle. Ideal storage solutions include a magnetic knife strip, a knife block with individual slots, a knife roll, or individual blade guards (saya) made of wood or plastic. These methods protect the sharp edge from damage and prevent accidental cuts. Proper storage not only preserves the knife but also ensures safety in the kitchen. By adhering to these simple cleaning and storage practices, you can significantly extend the life and performance of your valuable Japanese knives. Neglecting these steps can lead to irreversible damage and diminish the knife’s performance over time. A well-maintained knife is a joy to use.

Addressing Chipping and Patina: Understanding Blade Characteristics

Understanding chipping and patina is crucial for properly caring for

japanese paring knives and dispelling myths about their “delicacy.” Chipping, though less common with proper use, can occur, especially with very hard, thin-bladed knives used on inappropriate surfaces or for tasks they aren’t designed for (e.g., cutting through bones, frozen food, or highly dense materials). Japanese blades are designed for precision slicing and pushing, not hacking or prying. Using a soft cutting board (wood or high-density plastic) is paramount to prevent chipping. If a small chip does occur, it can often be repaired with lower grit water stones and patience, carefully grinding down the chipped area and then re-establishing the edge. This is a testament to the fact that these knives are repairable, not disposable, if damage occurs.

Patina, on the other hand, is not a defect but a natural and desirable characteristic of carbon steel

japanese paring knives. It is a protective layer of oxidation that forms on the blade’s surface over time, resulting from exposure to acids and moisture in food. This layer typically appears as a blue, gray, or black discoloration. Patina helps protect the reactive carbon steel from more harmful red rust and often indicates a well-used and cared-for knife. It is part of the knife’s story and character. While some prefer a pristine, shiny blade, others cherish the unique aesthetic and protective qualities of a developing patina. It changes the look of the knife over time, giving it a unique character. For those unfamiliar with carbon steel, the appearance of patina might initially be confused with rust, but it’s important to understand the distinction.

Embracing these characteristics – understanding that chipping is often preventable through proper use and that patina is a natural evolution for carbon steel – helps demystify the maintenance of

japanese paring knives. It reinforces that with knowledge and respectful handling, these knives are robust tools built for longevity, not fragility. They are designed to adapt and perform, evolving with their owner’s culinary journey. A blade with a beautiful patina tells a story of countless meals prepared and memories made, making it a truly personal tool. This deep understanding empowers users to enjoy their knives without undue concern, fully appreciating their unique properties. The aesthetic appeal of a well-developed patina is often a point of pride for knife enthusiasts.

Curating Your Collection: Identifying the Best Japanese Paring Knives for Your Needs

Navigating the vast world of

japanese paring knives to identify the “best” one for your needs can be a daunting task. The ideal knife is not simply the most expensive or the one with the highest HRC rating; rather, it’s the one that perfectly matches your specific culinary tasks, ergonomic preferences, maintenance commitment, and budget. Curating your collection means making informed choices, understanding that each knife possesses unique characteristics that make it suitable for different users and applications. This section will guide you through the process of evaluating options, from renowned brands to artisanal makers, and discerning true quality beyond just the price tag.

Building a thoughtful knife collection is an investment in your culinary journey. It involves considering factors such as blade length (petty knives typically range from 120mm to 150mm), steel type (stainless vs. carbon), handle style (Wa vs. Western), and overall balance. By focusing on these elements and understanding what truly differentiates high-quality

japanese paring knives, you can confidently select tools that enhance your precision, comfort, and enjoyment in the kitchen. The perfect knife becomes an extension of your hand, making even the most intricate tasks feel effortless. A well-curated collection should reflect your personal cooking style and needs, providing the right tool for every job.

Renowned Brands and Artisanal Makers: What Sets Them Apart

The world of

japanese paring knives is rich with both globally renowned brands and smaller, highly respected artisanal makers, each offering distinct advantages. Major brands like Shun Cutlery, Tojiro, and Global are known for their consistent quality, sophisticated manufacturing processes, and often wider availability. Shun, for instance, based in Seki City, Japan, combines traditional techniques with modern technology, producing knives with VG-10 or SG2 steel cores clad in beautiful Damascus patterns. Their knives are recognized for their out-of-the-box sharpness, ergonomic Western-style handles, and generally good edge retention, making them popular among home cooks and professionals alike. Tojiro offers excellent value, providing high-performance blades at accessible price points, often utilizing VG-10 or DP Cobalt alloy steels.

Artisanal makers, often small, family-run smithies, offer a different experience. Names like Yoshimi Kato, Yu Kurosaki, or Tanaka are revered for their unique craftsmanship, often working with traditional carbon steels (like Aogami or Shirogami) and employing meticulous hand-forging techniques. These makers produce knives that are truly one-of-a-kind, often with slight variations that reflect the hand of the smith. Their blades can achieve incredibly fine edges and often possess exceptional cutting feel, known as “kiritsuke.” However, knives from artisanal makers can be harder to acquire, more expensive, and may require more specialized care, especially if they are reactive carbon steel. They often appeal to enthusiasts who value the story and individuality behind each blade. These knives embody centuries of accumulated knowledge and skill.

What sets these two categories apart is primarily scale of production and the degree of handcraftsmanship. Large brands offer reliability and broad appeal, while artisanal makers provide unique, often more specialized, and profoundly handcrafted tools. When choosing

japanese paring knives, consider whether you prioritize consistent quality and widespread availability or a bespoke, handcrafted piece with a distinct character. Both categories offer excellent performance, but cater to different preferences and levels of engagement with the knife’s lineage. Owning a knife from an artisanal maker can feel like owning a piece of history, connecting you to ancient traditions. They often have subtle characteristics that are highly prized by collectors and serious chefs.

Budget vs. Premium: The True Value Proposition in Japanese Paring Knives

When approaching the purchase of

japanese paring knives, the spectrum of price points, from budget-friendly options to high-end premium blades, can be vast. It’s crucial to understand that “budget” does not necessarily equate to “poor quality,” nor does “premium” automatically guarantee the “best” knife for everyone. The true value proposition lies in the balance between performance, durability, maintenance requirements, and your individual needs. Entry-level Japanese petty knives (e.g., from brands like Tojiro DP or Fujiwara FKM) can offer excellent performance for their price. They often use reliable stainless steels like AUS-8 or VG-10, providing good sharpness and edge retention, suitable for most home cooks. These knives are often factory-sharpened to a good standard and are relatively easy to maintain, making them a superb starting point for exploring Japanese cutlery without a significant financial commitment. They represent fantastic value and are perfectly capable of handling daily kitchen tasks with precision.

Premium

japanese paring knives, on the other hand, typically feature rarer or more complex steels (e.g., SG2, ZDP-189, Aogami Super), intricate hand-forging processes, and meticulous finishing. These knives can achieve extraordinary sharpness, superior edge retention, and often possess a unique aesthetic appeal (e.g., elaborate Damascus patterns, exquisite handle materials). They are an investment, offering a level of cutting performance and craftsmanship that justifies their higher cost for serious enthusiasts or professional chefs. However, these premium blades may require more advanced sharpening skills and diligent care, especially carbon steel variants. Their value is derived from their unparalleled performance, artisanal beauty, and longevity when properly maintained. The enhanced cutting experience and prestige often associated with premium knives are significant factors for many buyers.

The “true value” of

japanese paring knives is subjective. For a casual cook who wants a precise peeling knife that’s easy to care for, a budget-friendly VG-10 petty might offer the best value. For a culinary professional or enthusiast seeking peak performance, exceptional edge retention, and a blade that is a joy to use and admire, a premium hand-forged knife might be the superior value. It’s about aligning the knife’s capabilities and characteristics with your expectations, usage frequency, and willingness to invest in maintenance. Don’t be swayed solely by price; consider the full spectrum of features and how they apply to your specific culinary journey. Investing in a knife that fits your needs perfectly, regardless of price, is what truly provides value. The right knife for you is the one that you will use and love for years to come.

What to Look For: Assessing Quality Beyond Price Tag

Assessing the quality of

japanese paring knives goes far beyond simply looking at the price tag. Several key indicators reveal true craftsmanship and performance potential. Firstly, examine the blade’s fit and finish. Look for a perfectly straight blade with no visible warping or irregularities. The grind should be even and symmetrical (unless it’s a single-bevel knife, where it should be intentionally asymmetrical and consistent). A well-executed distal taper, where the blade gradually thins from the heel to the tip and from the spine to the edge, indicates superior forging and balance. The choil (the unsharpened part of the blade just above the heel) should be smooth and comfortable, with no sharp edges that could dig into your finger during a pinch grip. These subtle details speak volumes about the maker’s attention to detail and precision. A properly ground blade will cut more efficiently and with less effort.

Secondly, pay attention to the transition between the blade and the handle. Whether it’s a traditional Wa-handle or a Western-style handle, the bolster or ferrule should meet the blade seamlessly, without any gaps where food particles or moisture could accumulate. The handle itself should feel secure and well-balanced, neither too heavy nor too light for the blade. The material should be comfortable to grip, even when wet, and securely affixed to the tang with no wobbling. The overall balance of the knife, as discussed earlier, is crucial; it should feel like an extension of your hand, not a cumbersome tool. For

japanese paring knives, this balance often leans slightly blade-forward, aiding in precision. A perfectly fitted handle enhances safety and control.

Finally, consider the steel type and its appropriate heat treatment. While specific steel names (VG-10, Aogami, etc.) indicate potential, the actual performance depends heavily on how well the steel was heat-treated. Researching the maker’s reputation for heat treatment can provide insight into the blade’s ultimate edge retention, toughness, and ease of sharpening. A reputable dealer or knowledgeable community can offer guidance. By focusing on these tangible indicators of craftsmanship and design, you can confidently assess the quality of

japanese paring knives, ensuring you invest in a tool that truly performs and endures, regardless of its sticker price. These criteria provide a more reliable measure of quality than mere brand recognition or cost, empowering you to make a truly informed decision. The sound of the blade on the stone when sharpening can also indicate steel quality.

The Unvarnished Truth About Japanese Paring Knives

The journey through the world of

japanese paring knives reveals a truth far richer and more complex than common myths suggest. These knives are not merely smaller versions of their Western counterparts; they are precision instruments born from centuries of artisanal mastery and a distinct culinary philosophy. Their design prioritizes acute sharpness, remarkable edge retention, and ergonomic balance, making them indispensable for intricate tasks that demand finesse and accuracy. The nuances of their blade steels, handle types, and the meticulous processes of hand forging and cladding all contribute to their superior performance and unique character. We hope this comprehensive exploration has provided a clear and unvarnished perspective on what truly sets these knives apart.

By debunking the myths surrounding their fragility, limited utility, and maintenance complexity, we aim to foster a deeper appreciation for these remarkable tools.

japanese paring knives are robust, versatile, and, with proper care, incredibly durable. They offer an unparalleled cutting experience that can elevate any kitchen task, from the simplest peel to the most elaborate garnish. Embracing the truth about these knives means recognizing their potential as an extension of your own culinary skills, enabling you to achieve results with greater precision and less effort. Their elegance in design is matched only by their superb functionality, making them a true joy to use for any chef. The experience of using a well-crafted Japanese paring knife is truly transformative, bringing efficiency and artistry to the kitchen.

Reclaiming Precision: Beyond the Myths

Reclaiming the true narrative of

japanese paring knives means moving beyond the often-limiting myths that have obscured their actual capabilities. No longer can they be dismissed as just delicate peeling knives; they stand as symbols of precision, control, and versatility in the culinary world. Their thin, hard blades, meticulously sharpened to acute angles, are engineered not for brute force, but for delicate, surgical accuracy, enabling cooks to perform intricate tasks with unparalleled finesse. This precision extends to every aspect of their design, from the subtle curve of the blade to the ergonomic balance of the handle, ensuring that every cut is deliberate and clean. The understanding that these knives are designed for precision, not brute strength, is key to unlocking their full potential. They are tools for artists, not just for utility.

The myths of fragility and difficult maintenance also dissolve under closer scrutiny. While they demand respect and specific care practices,

japanese paring knives are built to last, their longevity a testament to superior steel and craftsmanship. Embracing the proper honing and sharpening techniques, along with diligent cleaning and storage, transforms them from perceived delicate objects into reliable, long-term partners in the kitchen. By understanding their true nature, home cooks and professionals alike can confidently wield these instruments, unlocking a new level of culinary artistry. The unvarnished truth reveals a category of knives that are both robust and refined, offering a gateway to a more precise and enjoyable cooking experience. This clarity allows users to approach their knives with confidence, leading to a more satisfying culinary journey. A well-cared-for Japanese paring knife will be a loyal companion for decades.

Embracing the Craft: A Call to Deeper Understanding

Ultimately, the exploration of

japanese paring knives is a call to a deeper understanding—an invitation to embrace the rich craft and meticulous engineering behind each blade. It’s about appreciating the journey of steel from raw material to a precision cutting tool, shaped by generations of skilled artisans. This understanding goes beyond mere utility; it delves into the philosophy of efficiency, respect for ingredients, and the pursuit of culinary excellence that defines Japanese knife-making. When you pick up a petty knife, you’re not just holding a piece of metal and wood; you’re connecting with a legacy of dedication and artistry. This appreciation for the craftsmanship elevates the act of cooking into an art form.

By dispelling common misconceptions, we hope to empower cooks to make informed choices, select the right

japanese paring knives for their needs, and care for them in a way that preserves their unique qualities. This deeper appreciation fosters a respectful relationship with your tools, enhancing both their performance and your enjoyment in the kitchen. Embrace the nuance, learn the techniques, and allow the precision of a true petty knife to transform your culinary endeavors. It’s an investment not just in a tool, but in a philosophy of culinary excellence and artisanal heritage. The subtle beauty and profound functionality of these knives are best appreciated through hands-on experience and a willingness to learn their unique characteristics. This journey of understanding leads to a more fulfilling cooking experience. For additional knowledge, explore our category on all Japanese knives.

Explore More about Japanese Knives World: