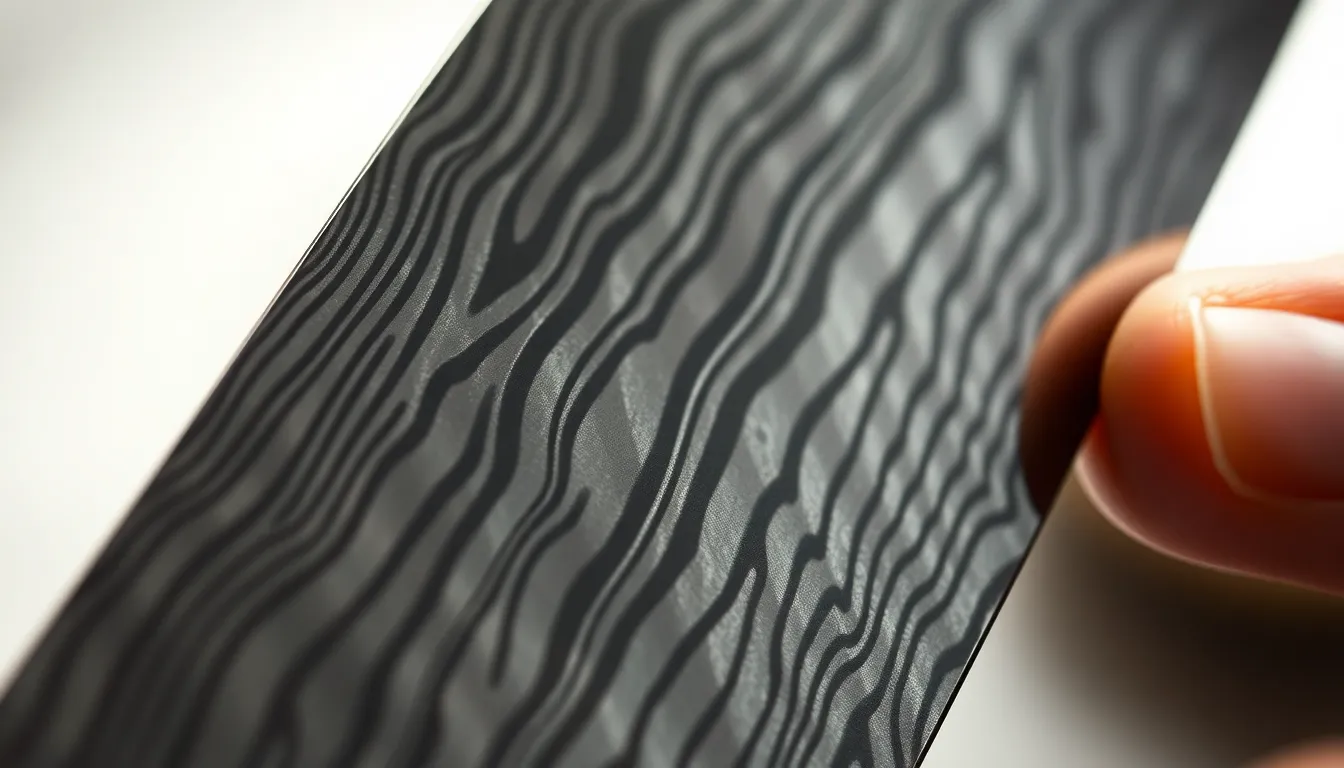

The world of culinary tools is vast and varied, but few items command as much admiration and intrigue as damascus steel japanese knives. These blades are not merely instruments for food preparation; they are a profound synthesis of ancient tradition, cutting-edge metallurgy, and artistic expression. Their distinctive wavy patterns, often reminiscent of flowing water or wood grain, tell a story of meticulous craftsmanship and unparalleled performance.

For centuries, Japanese bladesmiths have refined techniques passed down through generations, culminating in knives that are legendary for their sharpness, durability, and aesthetic beauty. The modern resurgence of damascus steel japanese knives has elevated them from niche collectibles to essential tools for professional chefs and passionate home cooks alike. Understanding the intricate details behind their creation and the benefits they offer transforms the act of cooking into a truly elevated experience.

This comprehensive guide will delve deep into the essence of these magnificent blades. We will explore the historical lineage that informs their contemporary design, unravel the scientific principles behind their exceptional performance, and provide practical advice on selecting and caring for your own damascus steel japanese knives. Prepare to uncover the secrets that make these knives a cornerstone of high-performance kitchens globally.

Unveiling the Enduring Allure of Damascus Steel Japanese Knives

A Legacy Forged: The Resurgence of Pattern-Welded Blades

The term “Damascus steel” evokes images of legendary swords from the Middle East, renowned for their incredible strength and mythical patterns. While the exact techniques of ancient Wootz Damascus have been lost to history, modern damascus steel japanese knives draw inspiration from its aesthetic and the principle of pattern welding.

Pattern welding involves folding and forging together multiple layers of different steels, creating a composite material with enhanced properties. This technique was independently developed in various cultures, including ancient Japan, where it formed the basis for samurai swords. The resurgence of pattern-welded blades in contemporary Japanese knife making applies these age-old methods to modern, high-performance steels.

Today’s damascus steel japanese knives are not just about beauty; they represent a pinnacle of metallurgical innovation. They marry the artistic heritage of pattern-welding with the precision and superior steel technology of modern Japan. This fusion results in blades that are both exquisitely beautiful and exceptionally functional, catering to the demands of today’s culinary landscape.

The journey of these knives from raw materials to gleaming culinary instruments is a testament to human ingenuity and dedication. Each blade carries with it the echoes of ancient smiths and the precision of contemporary artisans. This rich heritage contributes significantly to the enduring allure of damascus steel japanese knives, making them more than just tools—they are pieces of functional art. Learn more about the history of these materials on our knife materials page.

Setting the Stage for a Deep Dive into Craftsmanship and Performance

To truly appreciate damascus steel japanese knives, one must move beyond their captivating appearance and understand the meticulous processes that imbue them with their renowned capabilities. This journey requires an exploration into the core of their creation.

We will examine the selection of specific steel alloys, the intricate layering techniques, and the precise heat treatments that define their character. These elements combine to create a blade that not only holds an incredibly sharp edge but also boasts remarkable durability and flexibility.

Furthermore, we will dissect the functional advantages that set damascus steel japanese knives apart from their monosteel counterparts. This includes their superior edge retention, enhanced food release properties, and the inherent strength derived from their layered construction. Understanding these aspects will empower you to make informed choices and appreciate the sophisticated engineering behind each blade.

Our deep dive aims to demystify the complexities surrounding these premium kitchen tools. By the end, you will possess a comprehensive understanding of what makes damascus steel japanese knives a valuable investment for any serious cook. This knowledge will enhance your appreciation for the artistry and science encapsulated within every beautiful pattern.

The Intricate Craft: Deconstructing Damascus Steel Japanese Knives

Modern Damascus: Beyond Historical Lore and into Advanced Metallurgy

While the mystique of ancient Damascus steel persists, modern damascus steel japanese knives are products of advanced metallurgical science. Contemporary Damascus steel, often referred to as “pattern-welded steel,” is a meticulously engineered composite.

It typically consists of multiple layers—sometimes dozens, sometimes hundreds—of two or more different types of steel forged together. These steels are chosen for their contrasting properties, such as hardness, toughness, and corrosion resistance. The goal is to combine the best attributes of each steel into a single, superior blade.

For instance, one steel might be very hard, providing excellent edge retention, while another might be softer and tougher, offering flexibility and resistance to chipping. The forging process, involving repeated heating, hammering, and folding, meticulously binds these layers. This creates a homogeneous yet layered structure, foundational to the performance of damascus steel japanese knives.

The patterns emerge during the final stages of the process, particularly through acid etching. The acid reacts differently with the various steel alloys, causing one to darken more than the other, thus revealing the intricate, wavy patterns. This precise chemical reaction transforms a functional blade into a work of art.

The Core Steel Revelation: High-Carbon Foundations of Japanese Damascus Blades

At the heart of every high-performance damascus steel japanese knife lies a core steel, often referred to as the “cutting edge” steel. This core is the true workhorse of the blade, responsible for its sharpness and edge retention. While the surrounding Damascus layers provide strength, toughness, and aesthetics, the core steel is where the magic of cutting truly happens.

Japanese knife makers predominantly use high-carbon stainless steels or semi-stainless steels for the core. Popular choices include VG-10, AUS-10, and SG2 (also known as R2 powder steel). VG-10 is a widely acclaimed stainless steel known for its excellent balance of hardness, edge retention, and corrosion resistance, making it ideal for the demanding kitchen environment.

SG2, a powdered metallurgy steel, represents the cutting edge of steel technology, offering even higher hardness and exceptional edge retention due to its fine grain structure. The Damascus layers act as cladding, protecting this hard core steel from corrosion and adding a degree of shock absorption. This clever construction ensures that damascus steel japanese knives are not only sharp but also resilient.

The core steel’s composition and subsequent heat treatment are critical to the knife’s overall performance. Master smiths meticulously control these processes to bring out the optimal characteristics of the chosen steel. This dedication to material science is a hallmark of superior Japanese knife making.

The Aesthetic Symphony: How Layers and Etching Create Unique Patterns

The visually stunning patterns on damascus steel japanese knives are a direct result of the layering process combined with acid etching. Each pattern is inherently unique, a fingerprint of the forging process and the specific steels used.

During forging, layers are folded and hammered, often incorporating twists or manipulations to create different effects. Common patterns include “suminagashi” (ink flow), which mimics swirling water, “raindrop,” “ladder,” and “twist” patterns. These patterns are not merely superficial; they are integral to the blade’s structure.

Once the blade is shaped and polished, it undergoes an acid etching process, typically using ferric chloride. The different alloys in the layered steel react at varying rates to the acid. One steel type will etch darker and deeper, while the other remains brighter, revealing the intricate lines and contours of the pattern.

This differential etching highlights the topographical variations on the surface, making the hidden layers visible and creating a tactile experience. The aesthetic symphony created by these patterns makes each of the damascus steel japanese knives a unique piece of art. It speaks volumes about the skill and artistic vision of the bladesmith. Discover more about how these patterns are formed by exploring different Japanese knife types.

Performance Beyond Pattern: The Functional Superiority of Damascus Steel Blades

Edge Retention and Micro-Serration: Unpacking the Layered Advantage

One of the primary functional advantages of damascus steel japanese knives is their exceptional edge retention. This characteristic is often attributed to a phenomenon known as “micro-serration.” While the core steel provides the ultimate sharpness, the layered cladding contributes to how long that sharpness lasts.

When sharpened, the differential hardness of the various layers in the Damascus cladding can create a microscopically serrated edge. As the softer layers wear away slightly faster than the harder ones, minute peaks and valleys form along the cutting edge. These tiny “teeth” assist in slicing through tough materials, prolonging the perceived sharpness of the blade.

This layered structure also provides support to the incredibly hard and thin core steel. By cradling the cutting edge, the Damascus cladding helps prevent micro-chipping and rolling, common issues with extremely thin, hard edges. This structural integrity ensures that damascus steel japanese knives maintain their formidable sharpness through extensive use, reducing the frequency of sharpening.

The combination of a super-hard core and the supportive, micro-serrating cladding results in a blade that cuts efficiently and stays sharp for longer periods. This is a critical factor for professional chefs who rely on consistent performance during long hours of work. The unique construction of these knives truly elevates their cutting capabilities.

Durability and Flexibility: Dispelling Myths About Damascus Steel’s Resilience

There’s a common misconception that damascus steel japanese knives are purely ornamental and fragile. In reality, their layered construction often enhances their durability and flexibility, dispelling these myths. While ancient Damascus steel was known for these properties, modern pattern-welded steel also excels in these areas, albeit through different mechanisms.

The alternating layers of hard and softer steels create a composite material that resists catastrophic failure. The softer layers act as shock absorbers, preventing cracks from propagating through the entire blade. This means that while the core steel is incredibly hard for edge retention, the surrounding Damascus layers provide a degree of resilience, making the blade less prone to breakage or chipping under normal use.

Furthermore, the forging process refines the grain structure of the steels, contributing to overall toughness. This makes damascus steel japanese knives surprisingly robust for their thinness and hardness. They are designed to withstand the rigors of a busy kitchen, not just to look pretty on a knife magnet.

Proper heat treatment during manufacturing further enhances these properties, ensuring that the finished blade is not only hard enough to hold an edge but also tough enough to endure daily culinary tasks. This balanced approach to strength and flexibility makes them reliable companions in any kitchen. Explore how these properties compare with other materials on our knife materials section.

Food Release and Blade Geometry: The Unseen Benefits of Pattern Welding

Beyond sharpness and durability, damascus steel japanese knives offer an often-overlooked functional benefit: improved food release. The textured surface created by the differential etching of the Damascus pattern plays a subtle yet significant role in preventing food from sticking to the blade.

The slight undulations and microscopic pockets on the etched surface reduce the contact area between the blade and sliced food. This phenomenon, similar to how Granton edges work, creates air pockets that minimize suction, allowing ingredients like potatoes, cucumbers, or thinly sliced meat to fall away cleanly. This improves efficiency and makes prep work smoother and faster.

Furthermore, Japanese knives are renowned for their thin blade geometry, which is often enhanced by the Damascus cladding. The gradual taper from the spine to the edge, combined with the often-hollow ground or convex grinds, creates minimal resistance when cutting. The Damascus layers, particularly when ground to a very fine taper, contribute to this effortless glide through ingredients.

The combination of superior cutting geometry and enhanced food release makes slicing and dicing tasks remarkably effortless. This reduces fatigue during long prep sessions and contributes to a more enjoyable cooking experience. These unseen benefits solidify the position of damascus steel japanese knives as truly high-performance culinary tools.

Discernment and Distinction: Uncovering Quality in Damascus Steel Japanese Knives

Identifying Authenticity: Genuine Pattern-Welded vs. Cosmetic Etching

As the popularity of damascus steel japanese knives has grown, so has the market for imitations. It’s crucial for consumers to distinguish between genuine pattern-welded Damascus steel and blades with merely cosmetic, laser-etched patterns. The latter often lack the functional benefits of true Damascus and are purely for aesthetic appeal.

A true Damascus blade will have patterns that are visibly three-dimensional, with slight topographical variations you can feel. Run your fingernail over the surface; if it’s perfectly smooth, it’s likely a fake. Genuine patterns will also continue onto the spine and into the tang of the knife, though they might be less pronounced in polished areas.

Look closely at the edge. On a true Damascus blade, the layers will often be visible at the sharpened edge, albeit very finely. A fake Damascus pattern will abruptly stop or show no layering at the cutting edge. Another tell-tale sign is the consistency of the pattern across multiple identical knives from the same manufacturer; genuine Damascus patterns are inherently unique, while etched patterns will be identical.

Understanding these subtle differences is key to investing in authentic damascus steel japanese knives that offer both beauty and performance. A reputable vendor or manufacturer will always be transparent about their knife construction. For more insights on choosing the right knife, check out our buying guides.

Key Indicators of Superior Craftsmanship in Damascus Japanese Knives

Beyond authenticity, several indicators point to superior craftsmanship in damascus steel japanese knives. These details reveal the care and precision invested by the maker, leading to a truly exceptional tool.

Firstly, examine the fit and finish. The transition between the blade and the handle should be seamless, without gaps or rough edges. This not only speaks to aesthetic quality but also to hygiene and comfort during prolonged use. A well-finished choil (the unsharpened part of the blade just above the handle) and spine are also signs of attention to detail.

Secondly, consider the grind and edge geometry. A superior knife will have a thin, precise grind that tapers smoothly to an incredibly sharp edge. The bevels should be even and consistent along the entire length of the blade. This precise geometry is crucial for achieving effortless cuts and optimal food release.

Thirdly, the selection of core steel and its stated hardness (often in HRC – Rockwell Hardness Scale) provides insight into performance. Premium damascus steel japanese knives typically use high-performance steels like VG-10, SG2, or Aogami, hardened to 60-65 HRC. Finally, the overall balance of the knife in your hand is paramount. It should feel comfortable and extensions of your arm, facilitating precise control and reducing fatigue.

These indicators collectively demonstrate the mastery of the bladesmith and ensure that you are acquiring a blade that performs as beautifully as it looks. Investing in a knife with superior craftsmanship ensures longevity and culinary pleasure.

The Value Equation: Understanding Price Points and Investment in Premium Blades

The price spectrum for damascus steel japanese knives is wide, ranging from moderately priced options to high-end, artisan-forged masterpieces. Understanding the value equation helps you make an informed investment that aligns with your needs and budget.

The price of a Damascus knife is influenced by several factors: the quality and type of core steel (e.g., SG2 is generally more expensive than AUS-10), the number of layers in the Damascus cladding (more layers typically mean more complexity and cost), and the complexity of the forging process (e.g., hand-forged vs. factory-produced).

Brand reputation and the expertise of the bladesmith also play a significant role. Renowned Japanese brands with a long history of quality craftsmanship naturally command higher prices. Furthermore, the handle material and construction (e.g., natural wood, composite, full tang) can impact the final cost. While it’s tempting to opt for cheaper alternatives, remember that true damascus steel japanese knives are an investment.

A well-made Damascus knife, properly cared for, can last a lifetime, offering unparalleled performance and aesthetic pleasure. It’s not just a tool; it’s a piece of functional art that enhances your culinary journey. Consider your needs, budget, and the longevity you desire when making your selection. Sometimes, paying a little more upfront for quality saves money in the long run by avoiding frequent replacements.

Curating Excellence: A Professional’s Portfolio of Damascus Japanese Knives

Renowned Makers and Their Signature Damascus Steel Japanese Knife Series

The market for damascus steel japanese knives is enriched by several renowned makers, each with a unique approach to craftsmanship and signature series. These brands have earned their reputation through consistent quality, innovation, and a deep understanding of traditional techniques combined with modern metallurgy.

One of the most globally recognized brands is Shun Cutlery, part of the Kai Group, based in Seki City, Japan. Shun is famous for making high-quality kitchen knives, including many impressive Damascus steel lines like their Classic, Premier, and Kiritsuke series. Their Damascus patterns are often distinctive, and their VG-10 core steel blades are known for excellent edge retention and performance. You can explore their extensive range at Shun’s official website.

Another prominent name is Miyabi, part of the Zwilling J.A. Henckels group, also manufactured in Seki City. Miyabi knives are celebrated for their exquisite beauty, handcrafted finishes, and use of advanced steels like SG2. Their Miyabi Birchwood series, with its stunning Damascus patterns and D-shaped birch handles, is a testament to Japanese artistry and German engineering precision. Visit Miyabi’s official website to see their collections.

Sakai Takayuki, a brand from Sakai, Osaka, is also highly regarded. They offer a diverse range of damascus steel japanese knives, often using AUS-10, VG-10, or even harder carbon steels like Aogami Super for their cores, clad in beautiful Damascus patterns. Their knives are often handcrafted by individual master smiths, reflecting a long lineage of knife-making tradition. Other notable makers include Tojiro, Yoshimi Kato, and Yu Kurosaki, each bringing their unique flair to the world of Damascus blades.

These makers not only produce aesthetically pleasing knives but also ensure superior cutting performance, making them staples in professional kitchens and beloved by home cooks worldwide. Choosing a knife from these brands often guarantees a product of exceptional quality and durability.

Choosing Your Blade: Matching Damascus Knife Profiles to Culinary Tasks

Selecting the right damascus steel japanese knife goes beyond appreciating its beauty; it involves matching the blade profile to your specific culinary tasks. Japanese knives come in a variety of shapes, each optimized for different cutting techniques and ingredients.

The Gyuto, often referred to as a Japanese chef’s knife, is a versatile all-rounder, suitable for slicing, dicing, and mincing. Its gentle curve allows for a rock-chopping motion, while its pointed tip is excellent for precision work. For those who prioritize slicing and push-cutting, a Santoku knife, with its straighter edge and blunt tip, is an excellent choice. Its shorter blade is often preferred in smaller kitchen spaces.

A Nakiri, with its flat profile and blunt tip, is specifically designed for chopping vegetables with speed and precision, ensuring full contact with the cutting board. For delicate tasks like peeling, paring, and intricate garnishing, a small Petty knife (similar to a utility knife) is indispensable. The longer Yanagiba or Sujihiki, while often not made with Damascus cladding, are specialized slicing knives for raw fish or meats, but some variations might exist with a Damascus finish on the non-cutting parts.

Consider your most frequent culinary activities when choosing your Damascus blade. Investing in a knife profile that complements your cooking style will enhance efficiency and pleasure in the kitchen. A well-curated collection often includes a versatile Gyuto complemented by specialized knives for specific tasks. Explore our guide to Japanese knife types to learn more.

Handle Ergonomics and Materials: The Unsung Heroes of Performance

While the blade typically garners most of the attention, the handle of a damascus steel japanese knife is an unsung hero that significantly impacts its performance, comfort, and overall experience. Ergonomics and material choice are crucial for a knife that feels like an extension of your hand.

Japanese knife handles generally fall into two categories: Wa-handle (traditional Japanese) and Yo-handle (Western style). Wa-handles are typically lighter and often octagonal, D-shaped, or oval, designed for pinch grip users and offering excellent maneuverability. They are often made from beautiful natural woods like magnolia, ebony, or rosewood, sometimes with a horn or composite ferrule.

Yo-handles resemble Western knife handles, featuring a full tang construction and often made from composite materials like Micarta, Pakkawood, or G10, known for their durability and moisture resistance. They tend to be heavier, providing a different balance point that some users prefer. The material choice also affects grip, hygiene, and maintenance.

A well-designed handle provides a comfortable and secure grip, reducing hand fatigue during extended cutting tasks. It should balance harmoniously with the blade, ensuring control and precision. The aesthetic appeal of the handle materials also complements the beauty of the Damascus blade, creating a visually cohesive and pleasing tool. When selecting your damascus steel japanese knives, always consider how the handle feels in your hand; it’s a critical component for long-term satisfaction.

Sustaining Splendor: Advanced Care for Your Damascus Steel Japanese Knife

Specialized Cleaning and Storage Protocols for Layered Steel Blades

To sustain the splendor and performance of your damascus steel japanese knives, specialized cleaning and storage protocols are essential. Unlike many Western stainless steel knives, these blades require a bit more attention due to their high-carbon core and unique layered construction.

Firstly, always hand wash your Damascus knife immediately after use. Use warm water and a mild dish soap, and wipe the blade gently with a soft sponge or cloth. Never use abrasive scrubbers, as they can scratch the delicate etched patterns. Rinse thoroughly and, most critically, dry the knife completely and immediately with a clean towel. Leaving moisture on the blade, especially near the edge or between layers, can lead to rust or patina spots, particularly on the high-carbon core.

Avoid dishwashers at all costs. The harsh detergents, high heat, and prolonged exposure to moisture in a dishwasher can severely damage the blade, dull the edge, and degrade the handle material. For storage, a magnetic knife strip, a knife block, or a saya (wooden sheath) is ideal. These methods protect the sharp edge from dulling and prevent accidental damage to the blade and patterns. Never store your knife loosely in a drawer where it can bump against other utensils.

Proper cleaning and storage not only preserve the stunning aesthetics of your damascus steel japanese knives but also maintain their superior cutting performance for years to come. Consistency in these routines ensures your investment retains its value and functionality. Learn more about general knife care on our knife care page.

The Art of Sharpening: Maintaining the Edge and Pattern of Damascus Knives

Maintaining the razor-sharp edge of your damascus steel japanese knives is an art that, once mastered, ensures their peak performance. While professional sharpening is always an option, learning to sharpen your own knife on whetstones is a rewarding skill that allows for precise control over the edge geometry.

Japanese knives, including Damascus ones, are typically sharpened at a very acute angle (often 10-15 degrees per side) to achieve their characteristic keenness. Using a set of quality Japanese whetstones (typically a coarse, medium, and fine grit stone) is recommended. Start with a medium grit stone to refine the edge, then move to finer grits for polishing and achieving a hair-popping sharpness. Maintaining a consistent angle throughout the sharpening process is paramount.

When sharpening damascus steel japanese knives, the patterns on the blade will not be affected unless you sharpen excessively high up the blade face. The patterns are embedded layers within the steel itself, not just a surface coating. However, vigorous sharpening near the spine or excessive grinding can alter the visible pattern slightly by removing material from the etched surface. Focus on sharpening only the very edge of the blade.

Regular maintenance sharpening (honing on a ceramic rod or using a very fine grit stone) between full sharpening sessions will extend the life of your edge and keep your knife performing optimally. With practice, you’ll find that sharpening becomes a meditative process, connecting you more deeply with your culinary tools. For detailed sharpening instructions, visit our sharpening guide.

Patina Development and Preservation: Enhancing the Blade’s Unique Character

For damascus steel japanese knives with a high-carbon core or those featuring specific carbon steel layers within the Damascus cladding, a natural phenomenon known as “patina” development is common and often desirable. Patina is a protective layer of oxidation that forms on carbon steel surfaces, typically displaying shades of blue, gray, or brown.

Unlike rust, which is red and destructive, patina is a stable, non-corrosive layer that helps prevent further oxidation and adds to the blade’s unique character. It develops naturally over time through exposure to moisture and the acids present in food. Cutting acidic ingredients like onions, tomatoes, or citrus fruits can accelerate patina formation, sometimes even creating beautiful patterns within the Damascus itself.

To encourage and preserve a healthy patina, ensure your knife is always thoroughly dried immediately after use. While patina is beneficial, prolonged exposure to moisture can still lead to rust. If rust spots do appear, they can often be gently removed with a rust eraser or a mild abrasive like baking soda paste. It’s crucial to understand that patina is a sign of a well-used and cared-for carbon steel knife, embracing its living nature.

Many enthusiasts cherish the unique character that patina imparts to their damascus steel japanese knives. It tells a story of the blade’s journey and usage, enhancing its beauty and individuality over time. It is a natural part of owning and enjoying a high-performance, handcrafted tool. This process contributes to the sustainability and longevity of your knife, as detailed further on our sustainability page.

The Enduring Legacy of Damascus Steel Japanese Knives

Recapitulating the Fusion of Art, Science, and Culinary Precision

The journey through the world of damascus steel japanese knives reveals a profound fusion of art, science, and culinary precision. These blades are not merely cutting tools; they are masterpieces born from centuries of tradition, meticulous craftsmanship, and cutting-edge metallurgical innovation. Their allure lies not only in their breathtaking patterns but also in their exceptional performance.

We’ve explored how modern pattern welding techniques, inspired by ancient lore, create robust and flexible blades by combining contrasting steels. The revelation of the high-carbon core steel highlights the scientific foundation of their unparalleled sharpness and edge retention. The aesthetic symphony of layers and etching transforms each knife into a unique, visual marvel.

Functionally, damascus steel japanese knives stand out due to their layered advantage, offering superior edge retention through micro-serration and enhanced durability that dispels common myths. Their precise blade geometry and subtle food release properties contribute to an effortless and efficient cutting experience, making them invaluable in any kitchen.

Discernment is key when investing in these premium tools, distinguishing genuine pattern-welded blades from cosmetic imitations. Understanding indicators of superior craftsmanship and the value equation ensures a wise investment. Finally, we’ve outlined how renowned makers like Shun and Miyabi continue to push the boundaries of quality, and how proper care, including specialized cleaning, sharpening, and patina preservation, sustains their splendor. The harmonious blend of beauty and utility makes damascus steel japanese knives a testament to human ingenuity.

Looking Forward: The Future of Damascus Steel in Modern Kitchens

The future of damascus steel japanese knives in modern kitchens appears brighter than ever. As culinary arts continue to evolve and home cooks increasingly seek professional-grade tools, the demand for high-performance and aesthetically pleasing knives will only grow. Advances in metallurgy will likely lead to even more innovative steel combinations, offering enhanced properties and pushing the boundaries of edge retention and corrosion resistance.

The embrace of sustainable practices in manufacturing, from responsible sourcing of materials to energy-efficient production processes, will also shape the industry. Artisans will continue to experiment with new forging techniques and handle materials, further diversifying the visual and tactile experience of these magnificent blades. We may see an even greater focus on ergonomic designs tailored to diverse cutting styles and hand sizes, ensuring optimal comfort for every user.

Furthermore, the growing appreciation for handcrafted goods and the stories behind them will ensure that the traditional skills of Japanese bladesmiths remain valued and passed down through generations. Damascus steel japanese knives will continue to represent a harmonious blend of form and function, embodying precision, durability, and beauty. They are more than just tools; they are enduring legacies of art and science, poised to inspire culinary creativity for countless years to come. Their presence in the kitchen transforms a routine task into an act of passion and appreciation for fine craftsmanship.

Explore more fascinating insights and products related to Japanese culinary tools and techniques on our website:

- Types of Japanese Knives

- Comprehensive Knife Care Guide

- Mastering Japanese Knife Sharpening

- Buying Guides for Japanese Knives

- Understanding Knife Materials

Visit Japaneseknivesworld.com for more.