The culinary world is replete with tools and techniques designed to elevate the cooking experience, but few instruments command as much respect and admiration as high-quality knives. Among these, japanese damascus kitchen knives stand out, renowned for their unparalleled sharpness, exquisite beauty, and storied heritage. These remarkable blades are not merely cutting tools; they are a synthesis of ancient forging traditions and modern metallurgical science, embodying centuries of Japanese craftsmanship and a relentless pursuit of perfection.

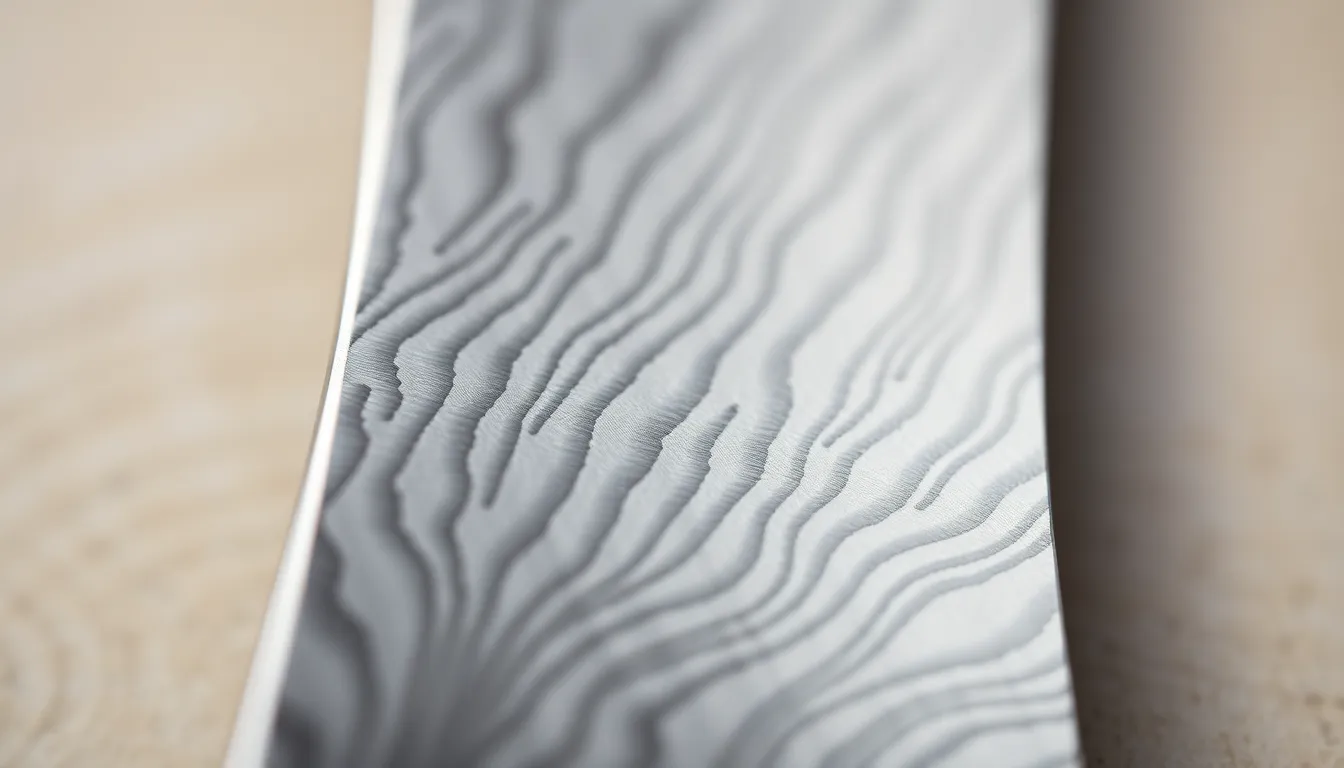

For professional chefs and passionate home cooks alike, investing in japanese damascus kitchen knives represents a commitment to precision and efficiency in the kitchen. Their distinctive wave-like patterns, often referred to as ‘hada’ or ‘mokume-gane’, are a testament to the intricate layering and folding processes that imbue each blade with unique character. This aesthetic appeal is matched only by their superior performance, offering an exceptional edge that holds its sharpness through countless preparations.

The Allure of Japanese Damascus Kitchen Knives

Beyond the Blade: Craftsmanship and Heritage

The history of Japanese knife-making is deeply intertwined with the nation’s martial traditions, evolving from the forging of legendary samurai swords. This rich heritage is palpable in every aspect of japanese damascus kitchen knives, from their meticulous construction to their precise balance. Artisans dedicate years, often decades, to mastering the complex techniques required to produce these blades, passing down knowledge through generations.

Each knife tells a story of dedication, patience, and an unwavering commitment to quality. The process involves multiple steps, including controlled heating, hammering, and layering different types of steel, often culminating in a blade that is both incredibly strong and surprisingly flexible. This blend of artistry and engineering ensures that japanese damascus kitchen knives are not just functional tools but also works of art.

The cultural significance of these knives extends beyond their utility; they are symbols of Japanese ingenuity and artistic expression. Many knife makers adhere to traditional methods, using charcoal fires and hand hammers, ensuring that a piece of history is embedded in every modern blade. This dedication to ancestral techniques, combined with an openness to contemporary advancements, defines the unique character of these culinary instruments.

What Sets Japanese Damascus Kitchen Knives Apart

Several key factors distinguish japanese damascus kitchen knives from their counterparts around the globe. Foremost among these is the exceptional hardness of their steel, which allows for a much finer and sharper edge. This hardness is achieved through specialized heat treatments and the use of high-carbon steels, often clad with softer stainless steels to provide durability and rust resistance.

The characteristic Damascus pattern is not merely decorative; it is a direct result of the forging process where multiple layers of steel are folded and welded together. This layering creates micro-serrations along the blade’s edge, enhancing its cutting ability and helping food release more easily. It also contributes to the blade’s overall strength and resilience against bending or breaking.

Furthermore, the asymmetrical grind of many Japanese blades, especially single-bevel knives, provides an incredibly acute cutting angle, allowing for precise and effortless slicing. This geometric advantage, combined with meticulous hand-finishing, contributes to the superior performance that chefs worldwide have come to expect from their japanese damascus kitchen knives. Understanding these nuances is crucial for any culinary enthusiast looking to explore the depth of Japanese blade craftsmanship. You can learn more about different knife types and their uses at Japanese Knives World – Knife Types.

The Authentic Craft: Deconstructing Japanese Damascus Kitchen Knives

Understanding the Layers: Core Steel and Cladding

At the heart of every true japanese damascus kitchen knife lies its core steel, the foundational material responsible for the blade’s ultimate sharpness and edge retention. This core is typically made from a very hard, high-carbon steel, often referred to as ‘Hagane’. Common choices include VG-10, AUS-10, SG2 (or R2 powder steel), and White or Blue Paper Steel (Shirogami and Aogami), each offering distinct performance characteristics.

VG-10, for example, is a stainless steel known for its excellent edge retention and corrosion resistance, making it a popular choice for many modern japanese damascus kitchen knives. On the other hand, traditional carbon steels like White Paper Steel offer unparalleled sharpness and ease of sharpening but require more diligent care to prevent rust. The core steel is the workhorse, providing the necessary hardness for a long-lasting, acute edge.

Surrounding this hard core is the cladding, often made of softer, more ductile stainless steel layers. These layers are folded and forge-welded to the core, creating the mesmerizing Damascus pattern. The cladding serves multiple purposes: it protects the brittle, hard core from impact and corrosion, adds flexibility to the blade, and provides the distinctive aesthetic appeal. The number of layers can vary significantly, from a few dozen to hundreds, influencing the complexity and beauty of the pattern. This intricate structure is what gives japanese damascus kitchen knives their unique blend of beauty and brawn.

It’s important to differentiate between true forge-welded Damascus and merely etched patterns. Genuine Damascus patterns are integral to the steel structure, formed by the physical layering and folding process. This structural integrity contributes to the blade’s performance, making it more resilient against lateral stress and chipping than a monolithic hard steel blade would be. The combination of a hard core and protective cladding ensures that the cutting edge remains incredibly sharp while the rest of the blade can withstand daily kitchen rigors.

The Art of Pattern Welding: Visuals and Functionality

Pattern welding is the ancient art responsible for the captivating aesthetic of japanese damascus kitchen knives. This technique involves repeatedly folding and hammering together multiple layers of different steels, typically a hard high-carbon steel and a softer, more flexible steel. As these layers are forged, they fuse together, and when the blade is later ground and polished, the distinct layers become visible as intricate, organic patterns.

The visual appeal of these patterns is undeniable, often resembling flowing water, wood grain, or even abstract art. Each Damascus knife is unique, with no two patterns being exactly alike, making them highly sought-after collector’s items. However, the beauty is not just skin deep; the pattern welding process also imparts functional benefits to the blade. The alternating layers of hard and soft steel create a cutting edge that is both incredibly sharp and remarkably resilient.

The softer layers provide ductility and shock absorption, preventing the harder, more brittle core from chipping easily, especially during demanding tasks. The minute undulations created by the pattern along the cutting edge can also contribute to a phenomenon known as “micro-serration,” which aids in cleaner cuts and helps prevent food from sticking to the blade. This synergy of visual artistry and practical engineering is a hallmark of truly exceptional japanese damascus kitchen knives.

Mastering pattern welding requires immense skill, precision, and an intuitive understanding of metal properties. The temperature control during forging, the number of folds, and the pressure applied all play a crucial role in the final pattern and the blade’s overall integrity. This labor-intensive process is a key reason why authentic japanese damascus kitchen knives command a premium price, reflecting the hours of dedicated craftsmanship poured into each piece.

Why Japanese Steel Matters: Hardness, Edge Retention, and Performance

The superior performance of japanese damascus kitchen knives is largely attributed to the exceptional quality of Japanese steel and the metallurgical expertise behind its treatment. Japanese steel manufacturers are renowned for producing high-carbon steels with incredibly fine grain structures, which are essential for achieving and maintaining a razor-sharp edge. This fine grain allows for an extremely thin edge geometry without compromising the blade’s stability.

Hardness, measured on the Rockwell scale (HRC), is a critical factor. While Western knives typically range from 54-58 HRC, japanese damascus kitchen knives often boast hardness levels between 60-65 HRC. This increased hardness means the steel can be ground to a much finer angle, resulting in a significantly sharper edge that requires less force to cut. Furthermore, harder steel retains its edge for much longer, reducing the frequency of sharpening.

Edge retention, the ability of a blade to stay sharp over time and through use, is where Japanese steel truly shines. The combination of high carbon content, specific alloying elements (like vanadium and molybdenum), and precise heat treatment protocols leads to the formation of very hard carbides within the steel matrix. These carbides resist wear and abrasion, allowing the knife to maintain its keen edge through extensive use in the kitchen, from slicing delicate sashimi to chopping robust vegetables.

The performance benefits extend beyond mere sharpness. A knife made from high-quality Japanese steel, particularly a japanese damascus kitchen knife, offers superior cutting precision and a smoother glide through ingredients. This reduces fatigue during long hours of prep work and ensures cleaner cuts, which is vital for both presentation and flavor preservation. The commitment to metallurgical excellence is a cornerstone of Japanese blade making, defining the very essence of their superior cutting tools.

Essential Blade Profiles: A Professional’s Guide to Japanese Kitchen Knife Shapes

Gyuto, Santoku, Petty: Choosing the Right Japanese Damascus Knife for Every Task

The world of japanese damascus kitchen knives offers a diverse array of blade profiles, each meticulously designed for specific culinary tasks. Understanding these shapes is crucial for selecting the right knife to maximize efficiency and precision in the kitchen. Three of the most versatile and popular profiles are the Gyuto, Santoku, and Petty, each serving distinct purposes while exemplifying the quality of Damascus steel.

The Gyuto, often referred to as the Japanese chef’s knife, is an all-purpose blade highly adaptable to a wide range of tasks. Its profile is similar to a Western chef’s knife but typically thinner, lighter, and with a flatter edge profile towards the heel. A japanese damascus kitchen knife in a Gyuto shape excels at slicing, dicing, mincing, and chopping most ingredients, making it an indispensable tool for professional kitchens and home cooks alike. Its versatility makes it an excellent first choice for those new to Japanese knives.

The Santoku, meaning “three virtues” (referring to its proficiency with meat, fish, and vegetables), is another popular general-purpose knife. It typically features a shorter, flatter blade with a rounded spine that curves down to meet the edge, providing a straighter cutting edge compared to the Gyuto. Santoku japanese damascus kitchen knives are superb for push-cutting and chopping, offering excellent control and precision for smaller, more delicate tasks, making them a favorite in many households.

The Petty knife, akin to a Western paring or utility knife, is smaller in size, usually ranging from 120mm to 150mm. Its compact size and pointed tip make it ideal for intricate tasks such as peeling fruits and vegetables, intricate garnishing, or precise trimming of smaller cuts of meat. A japanese damascus kitchen knife in a Petty profile provides unparalleled agility and control for detailed work, complementing the larger workhorses in any knife roll. Choosing the appropriate blade profile for each task significantly enhances the culinary experience and efficiency.

Single Bevel vs. Double Bevel: Impact on Cutting Dynamics

A fundamental distinction in japanese damascus kitchen knives lies in their bevel geometry: single bevel (Kataba) or double bevel (Ryoba). This characteristic profoundly impacts the knife’s cutting dynamics, precision, and suitability for specific culinary applications. Understanding this difference is key to appreciating the specialized nature of many Japanese blades.

Single bevel knives, traditionally used for preparing sushi and sashimi, feature a blade that is sharpened on only one side, with the opposite side typically being concave (ura-suki) to reduce drag and assist in food release. This unique grind allows for an incredibly acute edge angle, often as low as 10-15 degrees, resulting in unparalleled sharpness and the ability to make incredibly precise, thin slices. Examples include Yanagiba (slicers for raw fish), Deba (heavy-duty fish butchering), and Usuba (thin vegetable cutters). The precision offered by a single bevel japanese damascus kitchen knife is unmatched for delicate tasks.

However, single bevel knives require a specific cutting technique and are typically designed for right-handed users (though left-handed versions exist). They are specialized tools that excel at their intended purpose but are less versatile for general kitchen tasks. The learning curve for mastering single-bevel knives can be steep, but the results in terms of precision and presentation are remarkable.

Double bevel knives, conversely, are sharpened on both sides of the blade, similar to most Western knives. This symmetrical grind makes them ambidextrous and much more versatile for a wide range of cutting techniques, including chopping, dicing, and rocking cuts. Most Gyuto, Santoku, and Petty japanese damascus kitchen knives are double bevel, making them excellent all-around performers suitable for everyday use in professional and home kitchens. While their edge angle might not be as acute as a single bevel, they still offer exceptional sharpness due to the quality of Japanese steel and craftsmanship.

The choice between single and double bevel depends on the user’s specific culinary needs and experience. Single bevel blades offer ultimate precision for specialized tasks, while double bevel blades provide versatility and ease of use for a broader spectrum of kitchen activities. Both types of japanese damascus kitchen knives embody superior craftsmanship, differing primarily in their approach to cutting dynamics.

Handle Ergonomics and Balance: The Unsung Heroes of Control

While the blade typically garners most of the attention, the handle and overall balance of japanese damascus kitchen knives are equally critical to their performance and user comfort. A well-designed handle provides a secure grip, reduces hand fatigue, and ensures precise control, making even prolonged cutting tasks feel effortless. The balance point of the knife profoundly influences how it feels in the hand, affecting maneuverability and reducing strain on the wrist.

Japanese knives commonly feature two main types of handles: Wa-handle (traditional Japanese) and Yo-handle (Western-style). Wa-handles are typically lightweight, made from wood (such as Magnolia or Rosewood), and often octagonal, D-shaped, or oval in cross-section. They are designed to be held lightly, allowing the blade’s weight to do most of the work. This light weight shifts the balance point further towards the blade, which can enhance nimbleness and precision, especially for delicate tasks. A traditional Wa-handle on a japanese damascus kitchen knife is a testament to minimalist design and functional beauty.

Yo-handles, on the other hand, are more similar to Western knife handles, often made from synthetic materials, composite woods, or stabilized wood. They are generally heavier and designed to fit snugly in the palm, providing a secure, full grip. Yo-handles typically shift the balance point closer to the bolster, offering a more robust and familiar feel for users accustomed to Western knives. Many modern japanese damascus kitchen knives come with Yo-handles, blending Japanese blade technology with Western ergonomic preferences.

Regardless of the handle style, the overall balance of the knife is paramount. A well-balanced knife feels like an extension of the arm, allowing for fluid and controlled movements. The perfect balance point can vary based on individual preference and cutting style, but typically it’s where the blade meets the handle or slightly forward. When considering japanese damascus kitchen knives, it’s essential to not only admire the blade but also to evaluate how the handle feels and how the knife balances in your hand, as these factors significantly impact long-term satisfaction and cutting efficiency.

Debunking Common Myths About Japanese Damascus Kitchen Knives

Is Damascus Just for Show? Function vs. Aesthetics

One of the most pervasive myths surrounding japanese damascus kitchen knives is that their distinctive patterns are purely aesthetic, offering no functional benefit. While the swirling, wavy patterns are undeniably beautiful and contribute significantly to the knives’ allure, they are far from just decorative. The Damascus pattern is a direct result of the forge-welding process, where multiple layers of different steels are hammered and folded together. This process imparts several functional advantages to the blade.

Firstly, the alternating layers of harder and softer steel create a blade that is both incredibly sharp and remarkably durable. The harder core steel provides the cutting edge, capable of achieving and maintaining exceptional sharpness. The surrounding softer layers act as a shock absorber, protecting the more brittle hard core from impact and lateral stress, which reduces the likelihood of chipping or breaking. This layered construction makes a japanese damascus kitchen knife more resilient than a blade made from a single, monolithic piece of hard steel.

Secondly, the slight irregularities and micro-undulations created by the Damascus pattern on the blade’s surface can aid in food release. These tiny air pockets or channels prevent ingredients from sticking excessively to the blade, making slicing and chopping smoother and more efficient. This is particularly noticeable when cutting starchy vegetables like potatoes or dense proteins. So, while the visual appeal is a major draw, the structural integrity and improved food release are tangible functional benefits inherent in true japanese damascus kitchen knives. It’s a testament to ancient craftsmanship meeting modern culinary demands.

Therefore, to dismiss Damascus as merely aesthetic is to misunderstand the profound engineering behind these magnificent blades. The intricate patterns are a visual manifestation of a process designed to optimize both sharpness and strength. They represent a harmonious blend of art and science, making japanese damascus kitchen knives not just tools, but masterpieces of functional design.

The Durability Question: Are Japanese Damascus Kitchen Knives Fragile?

Another common misconception is that japanese damascus kitchen knives are inherently fragile due to their exceptional sharpness and high hardness. While it is true that Japanese knives, especially those with very hard steel cores, are less flexible than their softer Western counterparts and thus more susceptible to chipping if misused, labeling them as fragile is an oversimplification. Their design prioritizes cutting performance and edge retention, not brute force.

The perception of fragility often stems from improper use. Japanese knives are designed for precision cutting and slicing, not for hacking through bones, frozen foods, or dense rinds with a twisting motion. Applying excessive lateral force or using them as a pry tool can indeed lead to chipping of the ultra-thin, hard edge. However, when used for their intended purpose, a well-made japanese damascus kitchen knife is remarkably durable and will provide years, if not decades, of superior service.

The layered construction of Damascus steel, with its softer cladding protecting the harder core, actually enhances the blade’s overall resilience. This structure helps dissipate stress and prevents the blade from shattering under normal use, making it less brittle than a solid blade of equivalent hardness. Furthermore, modern advancements in steel metallurgy and heat treatment have significantly improved the toughness of even very hard Japanese steels, making them more forgiving than traditional carbon steel blades.

Proper care and technique are key to the longevity of japanese damascus kitchen knives. Avoiding harsh cutting surfaces like glass or ceramic, using a gentle slicing motion, and storing them safely are simple steps that prevent damage. Far from being fragile, these knives are high-performance instruments that, with appropriate handling, demonstrate remarkable durability and provide an unparalleled cutting experience. For more on proper care and maintenance, visit Japanese Knives World – Maintenance and Care.

Sharpening Challenges: A Closer Look at High-Performance Edges

The reputation for difficulty in sharpening is another myth that often deters potential owners of japanese damascus kitchen knives. While it’s true that the high hardness and acute edge angles of these knives require specific sharpening techniques, it’s not an insurmountable challenge. The difficulty is often exaggerated, and with the right tools and a little practice, anyone can learn to maintain the razor-sharp edge of their Japanese blade.

Unlike Western knives that are often sharpened with pull-through sharpeners or electric grinders, japanese damascus kitchen knives thrive on whetstones (water stones). Whetstones offer precise control over the sharpening angle and grit progression, allowing for a truly refined edge. The high hardness of Japanese steel actually makes it respond exceptionally well to whetstone sharpening, taking on an incredibly fine and long-lasting edge that simply cannot be replicated by coarser methods.

The initial learning curve involves mastering the correct angle and maintaining consistency throughout the sharpening process. However, numerous online tutorials and local workshops can provide guidance. Once the technique is acquired, sharpening becomes a meditative and rewarding process that directly contributes to the knife’s performance. The very properties that give japanese damascus kitchen knives their superior edge—their hardness and fine grain structure—make them incredibly receptive to proper whetstone sharpening.

Moreover, because these knives hold their edge for a significantly longer time than softer steels, they require less frequent sharpening. This means that while the process might seem more involved, it’s a task you’ll undertake less often. Ultimately, the perceived challenge of sharpening is a small price to pay for the unparalleled cutting performance and edge retention that a well-maintained japanese damascus kitchen knife provides. Embracing the learning process opens up a world of culinary precision and satisfaction.

A Professional’s Portfolio: Top Brands and Their Signature Japanese Damascus Knives

Esteemed Makers: Shun, Miyabi, Yoshihiro, and Others

The market for japanese damascus kitchen knives is graced by several highly esteemed manufacturers, each with a unique approach to craftsmanship, material selection, and design. These brands have earned their reputation through consistent quality, innovative techniques, and a deep respect for traditional Japanese knife-making principles. Exploring their signature lines offers a glimpse into the pinnacle of culinary blade artistry.

Shun Cutlery, a brand under Kai Group, is perhaps one of the most recognizable names in the global market for japanese damascus kitchen knives. Based in Seki City, Japan, Shun combines traditional Japanese handcraftsmanship with modern manufacturing processes. Their Classic line, featuring VG-10 steel clad with 34 layers of Damascus, is incredibly popular for its balance, sharpness, and beauty. Shun knives are known for their razor-sharp edges and comfortable D-shaped PakkaWood handles, making them a superb entry point for many aspiring chefs. You can explore their range at Shun Cutlery Official Website.

Miyabi, part of the Zwilling J.A. Henckels group, represents a fusion of German engineering and Japanese blade artistry. Manufactured in Seki, Japan, Miyabi knives are celebrated for their exceptional hardness (often utilizing SG2 or ZDP-189 core steels) and exquisite Damascus patterns. The Miyabi Birchwood SG2 line, with its stunning 100-layer Damascus and beautiful Birchwood handles, is particularly renowned. Miyabi’s dedication to high-performance steel and meticulous finishing sets a high bar for premium japanese damascus kitchen knives. For more details, visit Miyabi Knives Official Website.

Yoshihiro is another highly respected brand, known for producing a wide range of hand-forged japanese damascus kitchen knives, from entry-level to professional-grade. They offer knives in various steels, including VG-10, AUS-10, and traditional carbon steels like White and Blue Paper Steel, often clad in beautiful Damascus. Yoshihiro places a strong emphasis on traditional craftsmanship, with many of their knives being truly handcrafted by master artisans. Their diverse portfolio ensures there’s a Yoshihiro knife for every need and budget, embodying the spirit of classic Japanese blade making.

Beyond these, numerous smaller, artisanal makers such as Konosuke, Sakai Takayuki, and Tojiro also produce exceptional japanese damascus kitchen knives. These craftsmen often specialize in specific types of knives or steel, offering bespoke quality and unique designs. When seeking truly unique pieces, exploring the offerings of these smaller, highly specialized makers can be incredibly rewarding, revealing the true depth of Japanese knife artistry.

Assessing Value: Price vs. Performance in Premium Kitchen Knives

When considering an investment in japanese damascus kitchen knives, understanding the relationship between price and performance is crucial. These are premium tools, and their cost reflects the superior materials, intricate craftsmanship, and often the significant labor involved in their creation. However, a higher price doesn’t always guarantee the “best” knife for every individual, and value must be assessed based on specific needs and expectations.

Entry-level japanese damascus kitchen knives, typically ranging from $100-$250, often feature VG-10 or AUS-10 core steels with fewer layers of Damascus cladding. These knives offer a significant upgrade in sharpness and edge retention compared to standard Western knives and are an excellent starting point for those looking to experience the benefits of Japanese blades. They provide fantastic performance for their price point, making them accessible yet highly effective.

Mid-range knives, usually priced between $250-$500, often utilize more advanced steels like SG2 (R2 powder steel) or offer a higher number of Damascus layers. These knives typically boast superior edge retention, enhanced toughness, and more intricate patterns. They represent a sweet spot for many serious home cooks and professional chefs, offering a significant jump in performance and aesthetic appeal without reaching the very top tier of pricing. The quality of fit and finish also tends to improve noticeably in this range.

High-end to artisanal japanese damascus kitchen knives can range from $500 to well over $1000, and sometimes into the thousands for truly bespoke pieces. These knives often feature exotic steels (like ZDP-189), traditional carbon steels (White/Blue Paper Steel), hundreds of Damascus layers, and intricate hand-finishing. The increased cost reflects the rarity of materials, the extreme skill of master smiths, and the often hand-forged, labor-intensive production methods. While these knives offer peak performance and are often collectors’ items, the incremental performance gain might not be as dramatic as the price jump for everyday use for some users.

Ultimately, assessing value involves considering your budget, frequency of use, desired performance, and aesthetic preferences. Investing in a high-quality japanese damascus kitchen knife, even at the entry-level, provides a significant improvement over mass-produced alternatives. The longevity and joy of using a truly exceptional blade often justify the initial investment, proving that value extends beyond the mere price tag. It’s about finding the right balance for your culinary journey.

Identifying Genuine Articles: Avoiding Counterfeits and Misrepresentations

The growing popularity of japanese damascus kitchen knives has unfortunately led to a proliferation of counterfeit products and misrepresentations in the market. Identifying genuine articles requires diligence and an understanding of what constitutes authentic Japanese craftsmanship. Avoiding fakes ensures you invest in a quality tool that lives up to its reputation, rather than a subpar imitation.

One of the most common misrepresentations involves knives advertised as “Damascus” that merely have a pattern etched onto the blade’s surface using acid, rather than true forge-welded layers. While these knives might look similar, they lack the functional benefits of genuine Damascus steel. To discern, look for a three-dimensional depth to the pattern; etched patterns often appear flat and uniform. Genuine japanese damascus kitchen knives will have variations in the pattern that hint at the underlying layers.

Another red flag is an unusually low price for a knife marketed as “genuine Japanese Damascus.” The intricate process of making these knives, coupled with the high quality of Japanese steel, makes them inherently expensive. Prices that seem too good to be true almost always are. Be wary of unbranded knives or those sold by unknown vendors, especially on discount websites that do not specialize in culinary tools.

Always purchase your japanese damascus kitchen knives from reputable dealers, specialty knife shops, or the official websites of known brands. These sources stand behind their products and can provide provenance and details about the knife’s construction, steel type, and origin. Look for clear labeling of the core steel (e.g., VG-10, SG2, Aogami), the number of Damascus layers, and the exact location of manufacture in Japan (e.g., Seki City, Sakai, Takefu).

Examine the fit and finish closely. Genuine japanese damascus kitchen knives exhibit meticulous attention to detail: seamless transitions between blade and handle, even grind lines, and a perfectly sharpened edge. Any signs of shoddy craftsmanship, such as uneven bevels, gaps, or rough finishes, suggest a lower quality product, regardless of its “Damascus” appearance. Doing your research and being an informed buyer are your best defenses against falling victim to counterfeits.

Sustaining Excellence: Comprehensive Care for Your Japanese Damascus Kitchen Knives

Sharpening Regimens: Whetstones, Stropping, and Professional Services

To truly sustain the excellence of your japanese damascus kitchen knives, a proper sharpening regimen is paramount. Unlike European knives that might tolerate steel honing rods, Japanese blades with their harder steels and acute edge angles thrive on whetstones. Whetstone sharpening not only restores a razor edge but also refines the blade geometry, ensuring optimal cutting performance.

The process typically involves a progression of whetstone grits: a coarser stone (e.g., 400-1000 grit) for repairing dull or damaged edges, a medium stone (e.g., 2000-4000 grit) for refining the edge and preparing it for polishing, and a fine finishing stone (e.g., 6000-8000+ grit) for achieving a mirror-polished, hair-popping sharpness. Maintaining a consistent angle is crucial; dedicated sharpening guides can assist newcomers. Regular light maintenance on a finer grit stone can significantly extend the time between full sharpening sessions, keeping your japanese damascus kitchen knives perpetually sharp.

After sharpening, stropping on a leather strop loaded with polishing compound is a vital final step. Stropping removes any microscopic burrs or wire edges left by the whetstone, truly refining the edge to its keenest possible state. It also polishes the edge, enhancing its ability to glide smoothly through ingredients. Stropping can be done frequently, even daily, to refresh the edge of your japanese damascus kitchen knife without removing significant material, thus extending the life of the blade.

For those uncomfortable with self-sharpening or dealing with significant damage, professional sharpening services specializing in Japanese knives are an excellent option. Experienced sharpeners possess the skill and specialized equipment to restore your blade to its factory sharpness without damaging its delicate geometry. While DIY sharpening offers control and convenience, professional services guarantee meticulous care for your valuable japanese damascus kitchen knives. Learning to sharpen your knives is a rewarding skill that deepens your connection to your tools. You can find more comprehensive guides on sharpening techniques at Japanese Knives World – Sharpening Guides.

Cleaning and Storage: Preserving the Blade’s Integrity and Beauty

Proper cleaning and storage are fundamental to preserving the integrity and exquisite beauty of your japanese damascus kitchen knives. Neglecting these simple steps can lead to corrosion, damage to the edge, and dulling of the captivating Damascus pattern. Consistency in care ensures your investment remains a source of pride and culinary efficiency for years to come.

After each use, immediately hand wash your japanese damascus kitchen knife with warm water and a mild dish soap. Avoid abrasive sponges or harsh chemicals that could scratch the blade or dull its finish. It’s crucial to never put Japanese knives in a dishwasher. The high heat, harsh detergents, and aggressive spraying can cause irreparable damage to the blade, handle, and the delicate edge. The dishwasher environment can also cause the wood handles to swell, crack, or warp, leading to handle instability.

Thoroughly dry the knife immediately after washing with a soft cloth. This step is critical, especially for carbon steel core Damascus knives, as moisture is the primary culprit behind rust and corrosion, which can mar the beautiful Damascus pattern. Even stainless clad Damascus knives benefit from immediate drying to prevent water spots and maintain their luster. Pay particular attention to the area where the blade meets the handle, as moisture can accumulate there.

For storage, avoid the common knife block if it’s not well-ventilated, as moisture can get trapped. Magnetic knife strips, in-drawer knife trays, or individual blade guards (saya) are superior options. Magnetic strips allow for air circulation and prevent blade-on-blade contact. In-drawer trays keep blades separate and protected. A traditional wooden saya, specifically fitted for your japanese damascus kitchen knife, offers excellent protection, especially for transport or long-term storage, preventing accidental nicks or scratches. Proper storage not only protects the blade but also ensures safety in the kitchen. Adhering to these cleaning and storage practices will ensure your blades remain in pristine condition, ready for their next culinary adventure. ✅

Troubleshooting Common Issues: Rust, Chipping, and Edge Degradation

Even with diligent care, issues like rust, chipping, and edge degradation can occasionally affect japanese damascus kitchen knives. Understanding how to troubleshoot these common problems can help mitigate damage and restore your blade to optimal condition, ensuring its longevity and performance.

Rust: This is most common on carbon steel core Damascus knives but can occur on stainless-clad versions if neglected. Small spots of rust (patina) can often be removed with a mild abrasive like Bar Keepers Friend, baking soda paste, or a rust eraser specifically designed for knives. For deeper rust, professional intervention might be needed. Prevention is key: always dry your japanese damascus kitchen knife immediately after washing, and if storing for long periods, consider applying a thin layer of food-grade mineral oil to the blade, especially for carbon steel. Keeping the blade dry and clean is the best defense against corrosion.💡

Chipping: This is perhaps the most dreaded issue for owners of hard-steel Japanese knives. Chipping often results from improper use, such as cutting into bones, frozen food, or extremely hard surfaces (glass cutting boards). It can also occur if the blade is dropped or subjected to lateral stress. Small chips can sometimes be sharpened out using coarse whetstones, gradually grinding down the blade until the chip is removed. Larger chips might require significant material removal or professional repair, which could alter the blade’s profile. To prevent chipping, always use your japanese damascus kitchen knife for its intended purpose and on appropriate cutting surfaces.🎯

Edge Degradation (Dullness/Rolling): While natural dulling occurs with use, rapid edge degradation or a “rolled” edge (where the very tip of the edge folds over) indicates either aggressive use, improper cutting technique, or a need for sharpening. A rolled edge can often be corrected by stropping or a quick pass on a fine whetstone at the correct angle. If the knife simply feels dull, it’s time for a proper sharpening session with whetstones. Consistent light honing with a ceramic rod (not a steel one) between sharpening sessions can also help maintain the edge. Addressing these issues promptly prevents them from escalating and keeps your japanese damascus kitchen knives performing at their peak.🔥

The Evolution of Excellence: Innovations in Japanese Damascus Knife Making

Emerging Materials and Technologies in Knife Forging

The world of japanese damascus kitchen knives is not static; it’s a dynamic field where ancient traditions meet cutting-edge innovation. While respect for heritage remains paramount, contemporary knife makers are constantly exploring emerging materials and technologies to push the boundaries of performance, durability, and aesthetic appeal. These advancements are ensuring that Japanese blade craftsmanship continues to evolve and excel.

One significant area of innovation is in core steel metallurgy. Beyond the classic VG-10 and traditional carbon steels, new powdered steels like SG2 (R2) and ZDP-189 are gaining prominence. These steels, manufactured using advanced powder metallurgy techniques, offer incredibly uniform grain structures, allowing for even higher hardness levels (up to 67 HRC for ZDP-189) with improved toughness and edge retention. While more challenging to sharpen, they deliver unparalleled performance, making them highly sought after for premium japanese damascus kitchen knives. The development of new steel alloys specifically optimized for kitchen use continues to be a frontier of innovation.

In terms of forging technology, while hand-forging remains revered, modern machinery and precise temperature control systems are being integrated into production processes. These advancements allow for greater consistency in the forge-welding of Damascus layers, leading to more uniform patterns and improved structural integrity. Some manufacturers are also experimenting with cryogenic treatment of blades after heat treatment, which further refines the steel’s microstructure, enhancing hardness, wear resistance, and toughness. This “sub-zero” process is subtly contributing to the superior performance of many contemporary japanese damascus kitchen knives.

Furthermore, innovations in handle materials and attachment methods are contributing to improved ergonomics, durability, and hygiene. Stabilized woods, advanced composites, and carbon fiber are increasingly used, offering greater resistance to moisture and temperature fluctuations than traditional wood, while still providing excellent grip and aesthetic appeal. These material and technological advancements ensure that japanese damascus kitchen knives remain at the forefront of culinary tool development, blending timeless artistry with modern science.

Artisanal Traditions vs. Modern Manufacturing: A Balancing Act

The production of japanese damascus kitchen knives navigates a fascinating tension between deeply rooted artisanal traditions and the efficiencies of modern manufacturing. This balancing act defines much of the industry, with different makers leaning more heavily towards one side or the other, or striving for a harmonious blend. Understanding this dynamic is key to appreciating the diversity within the market.

Artisanal traditions, often found in smaller, family-run workshops in regions like Sakai or Takefu, emphasize hand-forging, individual craftsmanship, and the passing down of skills through generations. These master smiths might forge a limited number of japanese damascus kitchen knives each year, with each piece being unique and bearing the subtle marks of the craftsman’s hand. They often use traditional carbon steels and labor-intensive processes, resulting in blades that are highly prized for their historical authenticity, soul, and often unparalleled sharpness, albeit requiring more diligent care.

On the other end of the spectrum are larger manufacturers who integrate modern machinery and precise control systems into their production lines. While still respecting traditional forms and steel properties, these companies utilize advanced equipment for processes like steel rolling, multi-layer cladding, and precise heat treatment. This allows for higher volume production, greater consistency in quality, and often more robust stainless Damascus options that are easier for the average user to maintain. Brands like Shun and Miyabi exemplify this blend, utilizing advanced technology to consistently produce high-quality japanese damascus kitchen knives for a global market.

The beauty of this balancing act is that it offers consumers a wide spectrum of choices. One can opt for a truly handmade, artisanal japanese damascus kitchen knife, embracing its unique character and the history embedded within its layers. Alternatively, one might choose a meticulously machine-assisted knife that offers superb performance, consistent quality, and modern convenience. Both approaches contribute to the continued legacy of Japanese blade making, ensuring that the art evolves while its core principles of excellence and precision remain intact.

The Global Impact and Continued Legacy of Japanese Blade Craft

The global impact of japanese damascus kitchen knives extends far beyond the kitchens of Japan, fundamentally influencing culinary practices and knife manufacturing worldwide. Their rise to prominence in the international market has spurred innovation, raised standards for sharpness and performance, and introduced countless chefs and home cooks to a new level of cutting precision. The legacy of Japanese blade craft is not only enduring but continuously expanding its reach and influence.

The distinct aesthetics and superior performance of japanese damascus kitchen knives have inspired manufacturers in other countries to adopt similar layered steel techniques and focus on high-carbon, thin-edged blades. This cross-cultural exchange has elevated the quality of kitchen knives across the board, pushing the boundaries of what is considered a high-performance cutting tool. The influence is seen in the prevalence of “chef’s knives” with a flatter profile more akin to a Gyuto, and a greater emphasis on harder steels in modern culinary knife lines globally.

Furthermore, the cultural appreciation for Japanese craftsmanship, patience, and attention to detail has grown significantly alongside the popularity of these knives. People are increasingly recognizing the value of tools that are not merely functional but are also works of art, embodying centuries of refined skill. This appreciation fosters a greater understanding of the importance of quality tools in any craft, from cooking to woodworking.

The continued legacy of Japanese blade craft is also driven by a new generation of artisans and enthusiasts. Social media and online communities dedicated to knives have created a global dialogue, allowing knowledge to be shared, techniques to be discussed, and new makers to emerge. This vibrant ecosystem ensures that the art of making japanese damascus kitchen knives remains dynamic, responsive to new demands, and continually pushes towards greater excellence. As long as there is a pursuit of culinary perfection, the legacy of these extraordinary blades will continue to flourish and inspire.

The Enduring Legacy of Japanese Damascus Kitchen Knives

A Summary of Craft, Performance, and Care

The journey through the world of japanese damascus kitchen knives reveals a profound fusion of artistry, precision engineering, and historical tradition. These blades are far more than just tools; they are a testament to centuries of relentless pursuit of perfection, evolving from the legendary swords of samurai to the indispensable instruments of modern kitchens. Their allure lies in a unique combination of breathtaking aesthetics and unparalleled cutting performance.

At their core, the craft of japanese damascus kitchen knives is defined by the meticulous layering of different steels, creating the distinctive and functional patterns. This process, known as pattern welding, ensures a blade that is both incredibly sharp due to its hard core steel (like VG-10 or SG2) and surprisingly resilient thanks to its softer, protective cladding. The result is an edge that holds its keenness for an extended period, making light work of demanding culinary tasks and providing effortless precision.

Their performance is further enhanced by specific blade profiles—such as the versatile Gyuto, the balanced Santoku, and the agile Petty—each designed for optimal efficiency in particular culinary applications. The choice between single-bevel and double-bevel designs further refines their cutting dynamics, catering to specialized needs from delicate sashimi slicing to robust vegetable preparation. Crucially, the thoughtful ergonomics and balance of their handles ensure comfortable and controlled use, reducing fatigue and enhancing the overall cutting experience.

Maintaining the excellence of these high-performance instruments requires a commitment to proper care. This includes regular sharpening with whetstones to restore and refine their acute edges, followed by stropping for ultimate keenness. Immediate hand washing and thorough drying after every use, along with appropriate storage methods, are vital to prevent rust and preserve the blade’s integrity and aesthetic appeal. By adhering to these simple yet crucial care routines, owners ensure their japanese damascus kitchen knives remain pristine and perform flawlessly for decades.

Investing in Culinary Artistry: The Long-Term Value Proposition

Acquiring japanese damascus kitchen knives is not merely a purchase; it is an investment in culinary artistry, a commitment to precision, and an embrace of heritage. The long-term value proposition of these extraordinary blades extends far beyond their initial cost, manifesting in enhanced performance, enduring beauty, and an elevated cooking experience that transforms daily tasks into moments of genuine pleasure. They are tools that truly pay dividends in the kitchen.

From a purely functional standpoint, the superior edge retention and cutting ability of japanese damascus kitchen knives mean less time spent sharpening and more time focused on creating. The precision they offer improves the quality of your cuts, enhancing the appearance, texture, and even flavor of your ingredients. This efficiency and precision not only make cooking more enjoyable but also contribute to professional results, whether in a restaurant kitchen or at home.

Beyond performance, the aesthetic beauty of a japanese damascus kitchen knife is a source of continuous satisfaction. The unique patterns, the gleaming finish, and the masterful craftsmanship make each knife a piece of functional art. Displaying these knives is as much a part of their enjoyment as using them, adding a touch of elegance and sophistication to any kitchen space. They become conversation pieces, reflecting a discerning taste and an appreciation for fine craftsmanship.

Furthermore, well-cared-for japanese damascus kitchen knives are remarkably durable. With proper sharpening, cleaning, and storage, these blades can last a lifetime and even be passed down through generations, becoming treasured family heirlooms. This longevity, coupled with their timeless design and enduring utility, makes them a sustainable choice that offers exceptional value over many years of use. They stand in stark contrast to disposable tools, embodying a philosophy of quality and craftsmanship built to last.

Ultimately, investing in japanese damascus kitchen knives is an investment in yourself as a culinary enthusiast. It elevates your skill set, deepens your appreciation for the tools of your trade, and transforms the everyday act of cooking into a more mindful and artistic endeavor. These knives are a true testament to the enduring power of human ingenuity and dedication, making them an invaluable addition to any kitchen. They are more than just knives; they are a legacy.🎯

Explore more fascinating insights and products related to Japanese knives on our blog: