The world of culinary arts is profoundly enriched by the precision, beauty, and heritage of japanese culinary knives. These aren’t merely tools for food preparation; they are a direct lineage from ancient sword-making traditions, embodying centuries of artisanal skill and philosophical depth. Each knife tells a story of meticulous craftsmanship, superior materials, and a commitment to unparalleled performance in the kitchen.

Understanding these unique blades involves delving into their construction, the types available, and the cultural significance that imbues them with such a distinguished reputation. From the initial forge to the final polish, every step in their creation is designed to produce an instrument that enhances the culinary experience. For insights into different categories of these exceptional tools, explore our comprehensive guide on Japanese knife types.

Unveiling the Mastery of Japanese Culinary Knives

The allure of japanese culinary knives stems from a perfect synthesis of form and function. Chefs and home cooks alike are drawn to their legendary sharpness, durability, and the sheer joy they bring to the art of cooking. This mastery isn’t achieved by chance but through generations of inherited knowledge and relentless pursuit of perfection.

The precision cutting enabled by these knives transforms ingredients, allowing for more delicate presentations and enhancing the flavors of food. It’s a testament to the belief that the right tools elevate the craft, making every slice and dice a deliberate and enjoyable act. The global appreciation for these tools continues to grow, reflecting their indispensable role in modern kitchens.

Beyond the Blade: The Philosophy and Heritage of Japanese Knife Making

The creation of japanese culinary knives is deeply rooted in a philosophy that emphasizes harmony, respect, and continuous improvement, known as “Kaizen.” This ethos extends from the selection of raw materials to the final sharpening process. Bladesmiths consider the knife a living extension of the chef’s hand, designed to work in synergy with the user.

Japanese knife-making heritage is a direct descendant of the samurai sword tradition, known as ‘nihonto’. The same principles of differential hardening, intricate laminations, and meticulous finishing are applied. This history is not merely a romantic notion but a practical foundation for the exceptional performance these knives offer. The dedication of a bladesmith is palpable in every finished piece, reflecting a spiritual connection to their craft.

The cultural significance of these tools means they are often passed down through families, embodying stories and culinary legacies. They are treated with reverence, a respect that underlines their profound utility and beauty. This deep heritage ensures that each knife is not just a utensil but a piece of art and history.

The commitment to excellence also manifests in the regional specializations across Japan, each area famous for distinct styles and techniques. For example, Sakai, Seki, and Takefu are renowned centers of knife production, each with its unique legacy and contribution to the world of japanese culinary knives. This geographical diversity adds another layer to their rich history.

What Truly Defines a Superior Japanese Culinary Knife?

A superior japanese culinary knife is defined by several key attributes that collectively contribute to its exceptional performance and longevity. Foremost among these is the quality of the steel. High carbon steels, often laminated, are favored for their ability to achieve and hold an incredibly sharp edge, though they require more careful maintenance.

The sharpness of a Japanese blade is legendary, often attributed to its harder steel and unique sharpening angles. These knives typically have a much finer edge angle (e.g., 10-15 degrees per side) compared to Western knives (e.g., 20-25 degrees per side). This acute angle allows for incredibly precise and effortless cutting.

Blade geometry is another defining factor. Many traditional Japanese knives feature single-bevel grinds, meaning one side is flat and the other is beveled. This design excels in precise tasks like filleting fish or slicing vegetables thinly. The balance of the knife, how it feels in the hand, and the craftsmanship of the handle also significantly impact its superiority.

Ultimately, a superior Japanese knife feels like an extension of the user’s hand, performing tasks with effortless grace and precision. It inspires confidence and creativity in the kitchen, making mundane prep work an enjoyable part of the culinary journey. The tactile feedback, the clean cuts, and the sheer beauty make them highly sought after by professionals and enthusiasts alike.

The Intricate Anatomy of Japanese Culinary Knives

Diving deeper into what makes japanese culinary knives so special requires an understanding of their intricate anatomy. Unlike their Western counterparts, Japanese knives often feature distinctive elements that are crucial to their specialized functions and superior performance. Every component, from the tip to the tang, is designed with purpose and precision.

The blade’s profile, the handle’s material, and the way they are joined together all contribute to the overall balance, control, and cutting efficiency. These elements are not merely aesthetic choices but are functional design decisions honed over centuries. Understanding these components empowers users to choose the right knife for their needs and appreciate the engineering behind them.

Blade Geometries: Understanding Single Bevel and Double Bevel Designs

The most striking difference in japanese culinary knives often lies in their blade geometry, primarily the distinction between single-bevel (kataba) and double-bevel (ryoba) designs. Single-bevel knives, like the Yanagiba or Usuba, are sharpened on only one side, with the other side typically flat or slightly concave.

This single-bevel design allows for an incredibly sharp and precise edge, making them ideal for delicate tasks such as filleting fish for sashimi or finely dicing vegetables. The flat back of the blade helps guide the cut, creating perfectly straight slices. However, they are handed, meaning a right-handed single-bevel knife is designed differently from a left-handed one, a critical consideration for users.

Double-bevel knives, on the other hand, are sharpened on both sides of the blade, similar to most Western knives. This design offers versatility and ease of use for a wider range of tasks. Popular double-bevel Japanese knives include the Gyuto and Santoku, which are often considered all-purpose kitchen knives.

While still incredibly sharp, double-bevel knives are generally more forgiving for everyday use and don’t require the specialized techniques associated with single-bevel blades. Their symmetrical edge allows for ambidextrous use, making them a common choice for those new to japanese culinary knives. The choice between these geometries depends heavily on the intended use and the user’s skill level.

The Core of Performance: High Carbon, Stainless, and Clad Steels

The soul of any japanese culinary knife lies in its steel. Japanese bladesmiths utilize a variety of steels, each with unique properties that dictate the knife’s performance, edge retention, and maintenance requirements. The two primary categories are high carbon steel and stainless steel, with clad constructions often combining their benefits.

High carbon steels, such as Aogami (Blue Steel) and Shirogami (White Steel), are renowned for their exceptional hardness and ability to take an incredibly fine, razor-sharp edge. These steels are favored by professional chefs for their superior cutting performance. However, they are reactive, meaning they can rust or tarnish if not properly cared for, and will develop a protective patina over time. You can learn more about knife maintenance to ensure their longevity.

Stainless steels, like VG-10, AUS-8, or SG2 (R2), offer excellent corrosion resistance and are easier to maintain, making them popular for home cooks and busy kitchens. While they may not achieve the absolute peak sharpness of the hardest carbon steels, modern stainless steels can still hold a fantastic edge and offer a good balance of performance and practicality. They are an excellent entry point for those exploring japanese culinary knives.

Clad steels, often seen as “Damascus” patterns, combine multiple layers of steel. A harder, high-carbon core steel forms the cutting edge, while softer, more flexible stainless steel layers are forged around it. This construction offers the best of both worlds: a super-sharp edge with increased durability and stain resistance for the outer layers. This technique not only enhances performance but also creates stunning visual patterns on the blade.

Handle Aesthetics and Ergonomics: Wa-Handles vs. Yo-Handles

Beyond the blade, the handle is a critical component of any japanese culinary knife, influencing comfort, balance, and control. Japanese knives typically feature two main types of handles: Wa-handles and Yo-handles, each with distinct aesthetics and ergonomic properties.

Wa-handles are traditional Japanese handles, typically made from natural materials like magnolia wood, pakkawood, or even exotic woods, and are often secured with a buffalo horn ferrule. They are lightweight and come in various shapes, such as octagonal, D-shaped (for right-handed users), or oval. Wa-handles are designed to be held with a pinch grip, offering excellent control and maneuverability.

Their lightweight nature shifts the balance point of the knife forward, allowing for more precise tip work and less wrist fatigue during extended use. The simple, elegant design of Wa-handles contributes to the traditional aesthetic of japanese culinary knives and often feels more connected to the blade itself. They are less prone to slipping even when hands are wet due to their textured surface.

Yo-handles, on the other hand, are Western-style handles, typically heavier and contoured to fit the hand, similar to European knives. They are often made from composite materials like Micarta, Pakkawood, or even stainless steel. Yo-handles provide a more familiar grip for many users and can balance the knife closer to the heel of the blade, offering a different feel and leverage.

The choice between a Wa-handle and a Yo-handle largely comes down to personal preference, grip style, and comfort. Many Western chefs prefer Yo-handles initially due to familiarity, while traditionalists and those seeking maximum precision often gravitate towards Wa-handles. Both styles are integral to the overall experience of using japanese culinary knives. You can delve into the specific advantages of different knife handle materials and designs for your kitchen needs.

Decoding the Diverse World of Japanese Culinary Knives by Function

The vast array of japanese culinary knives might seem daunting at first glance, but each type is purpose-built for specific tasks, reflecting the meticulous nature of Japanese cuisine. Understanding their functions is key to appreciating their design and maximizing their utility in the kitchen.

From general-purpose knives to highly specialized tools, there’s a Japanese knife designed to excel at virtually every culinary preparation. Choosing the right blade for the job not only makes cooking more efficient but also ensures better results and extends the life of your knife. The diversity of these blades is a testament to the culinary creativity they inspire.

The Versatile Trio: Gyuto, Santoku, and Petty Knives

For those new to the world of japanese culinary knives, the Gyuto, Santoku, and Petty knives form an excellent foundational trio, offering versatility for a wide range of kitchen tasks. These are often considered the “workhorses” of a Japanese knife collection, suitable for most everyday needs.

The Gyuto, meaning “cow sword,” is the Japanese equivalent of a Western chef’s knife. It features a curved belly that allows for rock-chopping motions, along with a pointed tip for delicate work. Available in various lengths, typically 210mm to 270mm, the Gyuto is incredibly versatile, adept at slicing, dicing, mincing, and chopping meat, fish, and vegetables. Its balanced design makes it a true all-rounder among japanese culinary knives.

The Santoku, meaning “three virtues” (meat, fish, and vegetables), is a popular general-purpose knife known for its straight edge and rounded “sheep’s foot” tip. Typically shorter than a Gyuto (165mm to 180mm), the Santoku is excellent for push-cutting and dicing, offering precision and control in a more compact form factor. Its versatility and comfortable handling make it a favorite for home cooks and professionals alike who appreciate the balance and efficient cutting style of japanese culinary knives.

The Petty knife is the Japanese equivalent of a paring or utility knife. Ranging from 120mm to 150mm, it’s perfect for smaller, more precise tasks where a larger knife would be cumbersome. This includes peeling fruits and vegetables, trimming meats, segmenting citrus, and other delicate prep work. Every kitchen can benefit from a well-made Petty knife, making it an indispensable part of a comprehensive set of japanese culinary knives.

Together, this trio can handle nearly all common kitchen tasks with efficiency and precision. They represent the adaptability and thoughtful design inherent in japanese culinary knives, providing a solid foundation for any aspiring chef or home cook. Learning to use each effectively enhances the overall cooking experience.

Precision for Produce: Nakiri and Usuba in Detail

When it comes to preparing vegetables with unmatched precision, two specific types of japanese culinary knives stand out: the Nakiri and the Usuba. These blades are designed for vegetable preparation, embodying the Japanese emphasis on meticulous food presentation and consistent cuts.

The Nakiri Bocho, often simply called Nakiri, is a double-bevel vegetable knife characterized by its straight blade profile and blunt, squared-off tip. Its design allows for full contact with the cutting board with each stroke, making it incredibly efficient for chopping, slicing, and dicing vegetables with speed and uniformity. The straight edge ensures that every slice is clean and complete, without the need for a rocking motion.

Nakiris are typically thinner than a Western cleaver, making them suitable for delicate work while still being robust enough for tougher produce. Their user-friendly design makes them accessible even for those new to japanese culinary knives, offering immediate improvements in vegetable preparation. The distinct ‘thwack’ of a Nakiri hitting the board is satisfying and indicative of a clean cut.

The Usuba Bocho, meaning “thin blade,” is the professional’s choice for highly precise vegetable work, particularly in traditional Japanese cuisine. Unlike the double-bevel Nakiri, the Usuba is a single-bevel knife, designed for ultimate sharpness and intricate cuts like katsuramuki (rotary peeling) or julienning vegetables into incredibly thin strands. This requires significant skill and practice to master.

Usubas come in two main regional variations: the Kanto Usuba, which has a blunt, square tip, and the Kamagata Usuba, featuring a pointed, sickle-shaped tip for more delicate carving and scoring. The single-bevel grind creates a hollow ground on one side and a sharp edge on the other, allowing for unparalleled precision and minimal resistance when slicing. Mastering an Usuba is a hallmark of a skilled chef working with japanese culinary knives.

Both the Nakiri and Usuba exemplify the dedication of Japanese knife makers to creating specialized tools that elevate specific culinary tasks. While the Nakiri offers broad accessibility and efficiency for everyday vegetable prep, the Usuba caters to the exacting demands of professional artistry. They are essential tools for anyone serious about vegetable preparation.

Specialized Blades: Yanagiba, Deba, and Sujihiki for Protein Preparation

For those who frequently work with proteins, particularly fish and meat, a set of specialized japanese culinary knives like the Yanagiba, Deba, and Sujihiki becomes indispensable. These knives are crafted to achieve perfect cuts, whether it’s filleting, slicing, or trimming.

The Yanagiba, meaning “willow blade,” is the quintessential single-bevel knife for slicing boneless fish fillets for sashimi and sushi. Its long, slender blade, typically 240mm to 360mm, allows for a single, long, smooth draw cut, minimizing cellular damage and preserving the delicate texture of the fish. The extreme sharpness and length ensure a clean, precise slice every time, which is paramount in Japanese cuisine.

Mastering the Yanagiba requires practice, as the single-bevel design can cause the blade to steer if not used correctly. However, once proficient, it delivers unparalleled results for raw fish preparation, making it a cornerstone among traditional japanese culinary knives for sushi chefs. Its elegant form is as functional as it is beautiful.

The Deba Bocho, a robust single-bevel knife, is designed for heavy-duty tasks like filleting whole fish, cutting through small bones, and butchering poultry. Its thick spine and substantial weight provide the power needed for these tasks, while its sharp edge ensures precise cuts. Unlike a Western cleaver, a Deba is not meant for chopping through large bones but for breaking down fish with precision.

Deba knives vary in size, with smaller ones for delicate fish and larger ones for heavier fish. The thick spine tapers to a fine edge, allowing for both powerful initial cuts and delicate filleting. It’s a versatile and powerful tool that requires respect for its sharp edge and specific cutting techniques. For proper usage and care, particularly for specialized tools, referring to guides on different knife steel types can be highly beneficial.

The Sujihiki, often called a “slicer,” is a double-bevel, long, and slender knife, similar in profile to a Yanagiba but designed for slicing cooked meats, roasts, and larger fish fillets. Its thin blade and long length allow for clean, effortless slices through large cuts of protein, minimizing tearing and creating beautifully presented portions. It’s a versatile slicing knife for both professional and home use, showcasing the adaptable nature of japanese culinary knives.

While the Yanagiba and Deba are traditional single-bevel specialists, the Sujihiki offers a more accessible double-bevel option for slicing large proteins. These three knives collectively represent the specialized precision that defines japanese culinary knives when working with various types of meat and fish, ensuring that every cut is made with mastery and care.

The Unseen Hand: Craftsmanship and Heritage Behind Japanese Knives

Behind every exceptional japanese culinary knife lies an unseen hand—the bladesmith—whose skill, dedication, and adherence to centuries-old traditions breathe life into the steel. This craftsmanship is not merely a manufacturing process; it’s an art form, deeply intertwined with the heritage and cultural values of Japan. The quality of a knife is a direct reflection of the artisan’s expertise and passion.

The journey of a Japanese knife from raw steel to finished product is a painstaking one, involving numerous steps, each executed with meticulous attention to detail. This section explores the fascinating world of traditional knife making, the pivotal roles of the artisans, and the unique finishes that celebrate their handiwork. It’s a narrative of dedication and artistry that elevates these tools far beyond mere utensils.

From Forge to Finish: Traditional Knife Making Techniques and Regional Centers

The creation of japanese culinary knives is a multi-stage process, often spanning days or weeks for a single blade, involving techniques passed down through generations. It typically begins with the forging process, where steel is heated and hammered repeatedly to refine its grain structure and create the desired blade shape. This process, known as “tanzo,” strengthens the steel and imbues it with resilience.

Following forging, the blade undergoes heat treatment, including quenching (rapid cooling) and tempering (controlled reheating). Quenching hardens the steel significantly, while tempering reduces its brittleness and increases toughness. This precise control over temperature and timing is crucial for achieving the desired hardness and durability for japanese culinary knives.

Many traditional Japanese knives feature a “san-mai” or “honsanmai” construction, where a hard core steel (hagane) forms the cutting edge, sandwiched between layers of softer steel (jigane). This lamination process, a direct descendant of sword-making techniques, provides a combination of incredible edge retention and blade flexibility, making the knife both sharp and durable.

After forging and heat treatment, the blade goes through extensive grinding and sharpening. This is a highly skilled process that shapes the blade’s geometry, creates the bevels, and refines the edge. Finally, the knife is polished, and the handle is fitted, often with exceptional precision to ensure perfect balance and comfort. The intricate steps highlight the artisanal investment in every piece of japanese culinary knives.

Japan boasts several renowned regional centers for knife making, each with its unique history and specialty. Sakai, in Osaka Prefecture, is famous for its single-bevel traditional knives, produced by a division of labor where different artisans handle specific steps of the process. Seki City, in Gifu Prefecture, is a major industrial hub, producing a wide range of both traditional and modern knives, including many popular brands. Echizen (Fukui Prefecture) and Tosa (Kochi Prefecture) are also significant regions, known for their distinct forging styles and the production of rustic, hand-forged blades. These regional differences add to the rich tapestry of japanese culinary knives.

The Role of the Bladesmith and Sharpening Master in Legacy Creation

The creation of a superior japanese culinary knife is a collaborative masterpiece, heavily reliant on the skills of two pivotal figures: the bladesmith (kajiya) and the sharpening master (togishi). Their combined expertise ensures that the blade not only possesses excellent steel properties but also achieves its legendary sharpness and functionality.

The bladesmith is responsible for the foundational work: selecting the steel, forging the blade, and performing the crucial heat treatments. This individual’s deep understanding of metallurgy, fire, and hammer control shapes the very soul of the knife. They must meticulously manage temperatures and striking forces to refine the steel’s grain structure and ensure consistent hardness throughout the blade. The bladesmith’s vision sets the stage for the knife’s ultimate performance.

Once the blade leaves the forge, it transitions to the sharpening master. This artisan is responsible for grinding the blade to its final geometry and applying the razor-sharp edge. This is a highly specialized skill, often requiring years of apprenticeship to master. The togishi uses a series of progressively finer whetstones, meticulously working the blade by hand to create the precise bevels and an incredibly acute edge.

The sharpening master’s role is not just about making the knife sharp; it’s about unlocking its full potential, ensuring perfect balance and optimal cutting performance. Their skill defines the knife’s ability to glide effortlessly through ingredients. The delicate dance between the bladesmith’s forging and the sharpening master’s refinement is what truly defines the legacy of japanese culinary knives. This division of labor allows for extreme specialization and mastery in each phase of the knife-making process, contributing to the unparalleled quality of these tools.

Embracing Imperfection: Kajiya, Kurouchi, and Other Artisanal Finishes

Beyond the polished beauty of some blades, many traditional japanese culinary knives proudly display artisanal finishes that embrace the raw beauty of the forging process, rather than concealing it. These finishes are not imperfections but rather marks of authenticity, telling a story of the hammer and the fire that shaped the blade. They add character and often offer practical benefits.

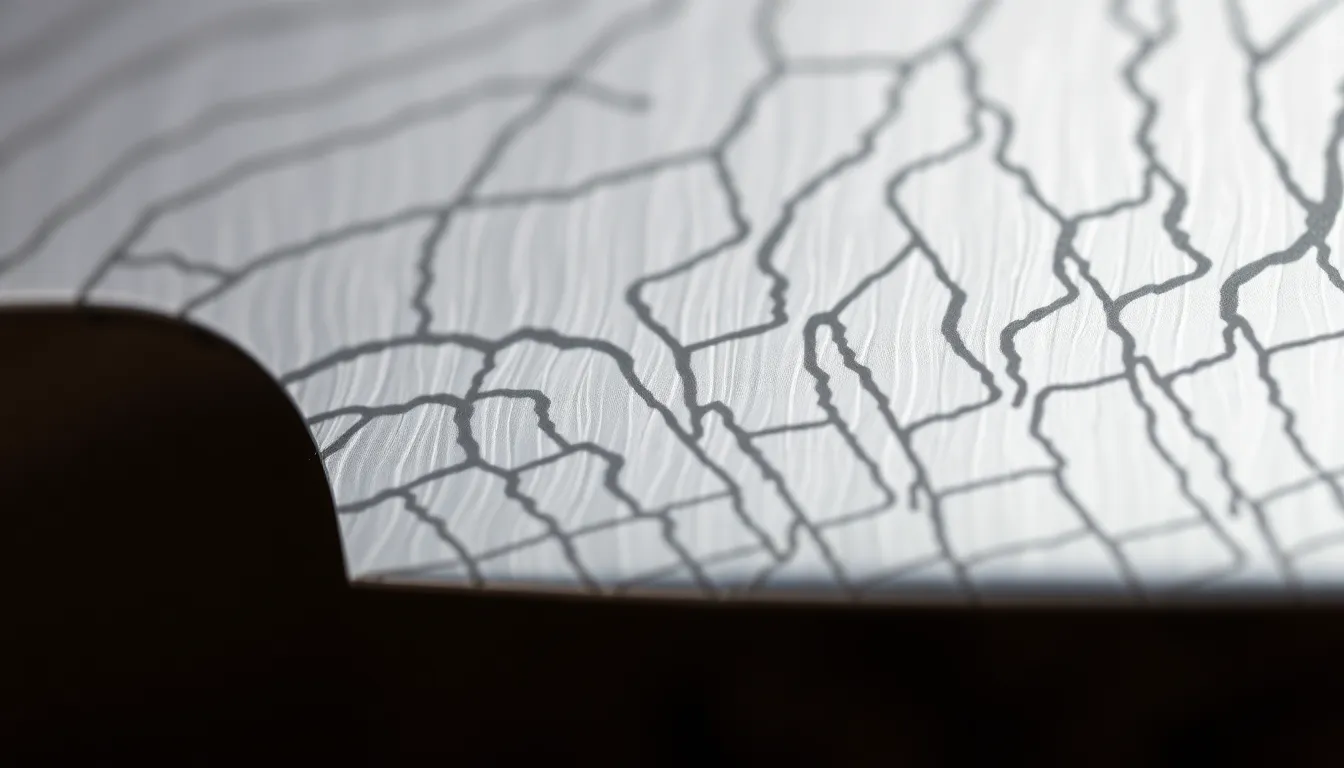

The “Kajiya” or blacksmith finish refers to the visible hammer marks left on the blade’s surface, particularly on the softer cladding layers. These subtle indentations are a direct testament to the hand-forging process and the skill of the bladesmith. Rather than being ground perfectly smooth, these marks are preserved, showcasing the raw, artisanal nature of the knife. It’s a celebration of the human element in creation.

Kurouchi (黒打ち), meaning “black forged,” is perhaps the most iconic rustic finish found on japanese culinary knives. It’s the residual black scale left on the upper portion of the blade after forging, which is not fully removed during grinding and polishing. This dark, almost charcoal-like finish contrasts beautifully with the polished edge and adds a distinctive, traditional aesthetic. Beyond its visual appeal, the kurouchi finish offers a practical benefit: it provides a protective, non-reactive layer that helps prevent rust on the reactive high-carbon steel underneath, especially useful for those learning about carbon steel knives.

Other traditional finishes include “Nashiji” (pear skin), which resembles the textured surface of a pear, and “Tsuchime” (hammered), featuring distinct, intentional hammer marks. Both Nashiji and Tsuchime finishes are not only aesthetically pleasing but also create air pockets between the blade and food, reducing friction and preventing food from sticking. This functional beauty is a hallmark of thoughtful design in japanese culinary knives. These finishes highlight that true perfection in Japanese craftsmanship often lies in the visible evidence of the artisan’s hand, embracing the unique textures and character imparted by traditional methods rather than striving for a machine-like uniformity. Each mark tells a story, making every knife a unique piece of art.

Beyond Initial Sharpness: Mastering Performance and Maintenance of Japanese Culinary Knives

Owning japanese culinary knives is a commitment that extends far beyond the initial purchase. Their legendary performance is not static; it’s a dynamic state that requires proper care, sharpening, and understanding. Without diligent maintenance, even the finest Japanese blade will eventually lose its edge and its remarkable capabilities. This section delves into the essential practices for preserving and enhancing the performance of these exquisite tools.

From mastering sharpening techniques to understanding the unique characteristics of high carbon steel, proper maintenance is key to a lifelong relationship with your Japanese knife. It’s an investment in your culinary journey, ensuring that your blades remain the precision instruments they were designed to be. Embracing this aspect of ownership is crucial for any enthusiast of japanese culinary knives.

Maintaining the Edge: Advanced Sharpening and Honing Techniques

The extreme sharpness of japanese culinary knives is one of their most celebrated attributes, but maintaining this edge requires specific techniques and tools. Unlike Western knives that are often honed with a steel rod, Japanese knives are best maintained and sharpened using whetstones (sharpening stones) and occasionally leather strops.

Whetstones come in various grits, ranging from coarse (around 200-400 grit) for repairing chips or significant dullness, to medium (1000-2000 grit) for regular maintenance and sharpening, and fine (4000-8000+ grit) for polishing the edge to a razor-sharp finish. The process involves soaking the stone, then carefully running the blade along its surface at the correct angle, creating a slurry that aids in sharpening.

For single-bevel knives, sharpening is a more intricate process, requiring precise angle control on both the primary bevel and the ura (flat back) side. The aim is to create a keen edge without altering the delicate geometry. For double-bevel knives, consistency in maintaining the symmetrical angle on both sides is crucial. Many enthusiasts find sharpening to be a meditative and rewarding process, a true connection to their japanese culinary knives.

Honing, often confused with sharpening, is a less abrasive process typically done with a ceramic or fine grit honing rod, or a very fine whetstone. It’s used to realign a slightly rolled edge that has lost its initial keenness, without removing significant material. Honing should be done regularly, perhaps every few uses, to extend the time between full sharpenings. However, for japanese culinary knives with extremely hard steel, a gentle touch is key to avoid micro-chipping. For a full breakdown on the process, check out our guide on how to sharpen Japanese knives.

Finally, stropping on a leather strop loaded with polishing compound can further refine and polish the edge, removing any burrs and making the blade incredibly sharp. This final step gives that “hair-shaving” edge that japanese culinary knives are famous for. Consistent care and proper technique will ensure your blades retain their legendary sharpness for years, making them a joy to use in any kitchen.

The Living Blade: Understanding Patina Development and Reactivity in High Carbon Steel

One of the unique characteristics of japanese culinary knives made from high carbon steel is their reactivity and the development of a patina. Unlike stainless steel, high carbon steel contains less chromium and is more susceptible to oxidation, which can manifest as rust if neglected, or a beautiful, protective patina if properly managed.

Patina is a natural, protective layer that forms on the surface of reactive steel as it interacts with acids and moisture from food. It appears as a darkening or discoloration of the blade, often in shades of blue, gray, brown, or even rainbow hues. This layer is not rust (which is typically red and flaky) but rather a stable form of oxidation that actually helps protect the underlying steel from more aggressive corrosion. Many chefs value the unique character and history a patina imparts on their japanese culinary knives.

To encourage a healthy patina and prevent rust, high carbon steel knives require immediate cleaning and drying after each use. Avoid leaving them wet or soaking in a sink, and never put them in a dishwasher. Acidic foods like onions, tomatoes, citrus, and proteins can accelerate patina development. Some enthusiasts even force a patina using substances like hot coffee or vinegar to achieve an even, stable protective layer quickly.

Embracing patina is part of the journey of owning high carbon japanese culinary knives. It tells a story of the knife’s use and its relationship with food. While the reactivity requires more vigilance in care, the superior edge retention and sharpening potential of high carbon steel are often considered well worth the effort. It’s a testament to the fact that these are living tools, evolving with their use and care.

Common Misconceptions and Troubleshooting for Japanese Knife Owners

Owning japanese culinary knives can come with a few misconceptions and challenges, especially for those accustomed to Western blades. Addressing these helps ensure proper care and optimal performance. One common misconception is that Japanese knives are fragile and chip easily. While their harder steel makes them brittle and susceptible to chipping if abused, they are not inherently fragile when used correctly.

They are designed for slicing and push-cutting, not for prying, twisting, chopping through bones (unless it’s a Deba used appropriately), or hitting against hard surfaces. Using a Japanese knife like a cleaver or for tasks it wasn’t designed for is the primary cause of chipping. For robust tasks, use a more forgiving knife or the appropriate specialized Japanese blade. Ensuring correct cutting techniques and avoiding misuse is key to preventing damage to these finely crafted tools. For a comprehensive list of what to avoid, see our article on Japanese knife care tips.

Another common issue is rust on carbon steel blades. As discussed, this is due to reactivity. Troubleshooting involves immediate cleaning and thorough drying after every use. If rust spots appear, they can often be removed with a mild abrasive like Bar Keepers Friend or a rust eraser specifically designed for knives. Regular application of camellia oil or mineral oil after cleaning also creates a protective barrier against moisture and air, preventing future rust on your japanese culinary knives.

Dullness is another frequent concern. Many new owners expect their Japanese knife to stay razor-sharp indefinitely without maintenance. The reality is that all knives dull with use. Troubleshooting dullness involves regular honing and periodic sharpening with whetstones. Waiting until the knife is completely blunt makes the sharpening process much harder. Learning to sharpen your own japanese culinary knives is an empowering skill that pays dividends in performance.

Finally, some owners struggle with food sticking to the blade. This can be mitigated by using specific blade geometries (like those with dimples or hammered finishes), but it’s also a matter of technique. A clean, precise cut often minimizes sticking. Understanding these common pitfalls and proactive troubleshooting ensures that your experience with japanese culinary knives remains one of precision and pleasure rather than frustration.

Curating Your Collection: A Professional’s Portfolio of Japanese Culinary Knives

For the serious cook, whether professional or dedicated home enthusiast, curating a portfolio of japanese culinary knives is an evolving journey. It’s about selecting the right tools that not only meet specific culinary needs but also resonate with personal style and technique. A well-chosen collection optimizes workflow, enhances precision, and makes cooking a more intuitive and enjoyable experience.

Building a collection isn’t about accumulating the most expensive blades, but rather about acquiring functional art pieces that serve a purpose and inspire creativity. This section guides you through the process of matching blades to tasks, identifying authentic quality, and looking towards the exciting future where tradition meets innovation in the world of japanese culinary knives.

Matching Blade to Task: Optimizing Your Kitchen Workflow and Technique

The hallmark of a skilled chef is not just their technique, but their ability to choose the right tool for the job. When it comes to japanese culinary knives, this principle is elevated due to their specialized designs. Optimizing your kitchen workflow begins with understanding which blade excels at which task and how it complements your cutting style.

For general-purpose chopping, dicing, and mincing, a Gyuto or Santoku is indispensable. Their versatility makes them the primary workhorse for most preparations. If you frequently break down large fish or poultry, a sturdy Deba will be invaluable for its strength and precision. For delicate slicing of raw fish for sushi or sashimi, a long Yanagiba ensures clean, single-pass cuts that preserve texture and presentation. Similarly, a Sujihiki excels at slicing cooked meats with minimal tearing.

Vegetable preparation sees a significant upgrade with a Nakiri or Usuba. A Nakiri makes quick work of uniform dicing and chopping, while an Usuba allows for incredibly thin and precise cuts, ideal for intricate garnishes or traditional Japanese vegetable preparations. For smaller, detail-oriented tasks like peeling, trimming, or intricate garnishing, a Petty knife is the perfect choice, offering maneuverability and control.

Consider your most frequent cooking activities and the ingredients you work with most often. Do you prepare a lot of vegetables? A Nakiri might be a priority. Are you an avid fish enthusiast? A Deba and Yanagiba would be excellent investments. Building your collection of japanese culinary knives should be a thoughtful process, adding specialized blades as your skills and culinary interests evolve, rather than buying a complete set all at once. This tailored approach enhances efficiency and elevates the quality of your cooking.

The Pursuit of Authenticity: Identifying True Quality and Value

In a market flooded with options, identifying true quality and value in japanese culinary knives requires discernment. Authenticity goes beyond a “Made in Japan” stamp; it encompasses the materials, craftsmanship, and the reputation of the smiths and brands. This pursuit is key to ensuring your investment brings lasting satisfaction and performance.

Look for knives from reputable Japanese regions known for their knife-making heritage, such as Sakai, Seki, Echizen, or Tosa. Researching the specific smith or brand (e.g., Shun Cutlery, Global Knives, Miyabi) can provide insight into their techniques and quality control. Authentic Japanese knives are often made with specific steel types like VG-10, SG2 (R2), Aogami, or Shirogami, which are indicators of high performance potential.

Examine the blade’s finish and grind. For traditional single-bevel knives, look for a consistent ura (concave grind on the back) and a well-defined primary bevel. For double-bevel knives, the grind should be symmetrical and taper smoothly to the edge. The fit and finish of the handle to the blade (the bolster or ferrule) should be seamless, with no gaps, indicating meticulous assembly. A well-balanced knife should feel comfortable and natural in your hand, with the balance point typically just forward of the handle.

Be wary of overly low prices for what claims to be a high-end Japanese knife; true craftsmanship and premium materials come at a cost. Conversely, a high price doesn’t always guarantee quality, so research and reviews are vital. Engaging with reputable vendors who specialize in japanese culinary knives and can offer detailed information about their products is crucial. They can often provide insights into the specific smiths, the steel, and the intended use of each blade, ensuring you invest in genuine quality and lasting value. Ultimately, an authentic Japanese knife will feel robust yet precise, inspiring confidence in every cut.

The Future of Japanese Culinary Knives: Innovation Meets Timeless Tradition

The world of japanese culinary knives is not static; it’s a dynamic realm where timeless tradition continually meets modern innovation. While the core principles of superior steel, meticulous craftsmanship, and specialized blade geometries remain, new technologies and design philosophies are shaping the future of these revered tools.

Innovations in steel metallurgy are constantly introducing new alloys that push the boundaries of hardness, edge retention, and corrosion resistance, without sacrificing the desired characteristics of traditional Japanese blades. Powder steels, for example, offer incredibly fine grain structures, allowing for even sharper and more durable edges. This ongoing research ensures that the performance of japanese culinary knives continues to improve.

Design innovations are also evident in handle materials and ergonomics. While traditional Wa-handles remain popular, modern composite materials offer enhanced durability, water resistance, and grip, catering to the diverse preferences of global chefs. Some manufacturers are experimenting with new blade profiles that blend traditional Japanese and Western characteristics, creating hybrid knives that offer broader versatility for various culinary styles.

Furthermore, the digital age is fostering greater accessibility and knowledge sharing about japanese culinary knives. Online communities, detailed reviews, and direct communication with artisans are making it easier for enthusiasts worldwide to learn, purchase, and appreciate these blades. This increased global interest also encourages more innovation as makers strive to meet diverse demands.

However, amidst this innovation, the fundamental respect for heritage and craftsmanship remains paramount. The future of japanese culinary knives is likely to be one where advanced materials and ergonomic designs enhance, rather than replace, the age-old techniques of forging, heat treatment, and hand-sharpening. The blend of past wisdom with future possibilities ensures that these knives will continue to be at the forefront of culinary excellence for generations to come, embodying a perfect balance of utility, beauty, and enduring legacy.

The Enduring Legacy and Future of Japanese Culinary Knives

The journey through the world of japanese culinary knives reveals more than just highly effective tools; it uncovers a profound cultural heritage, centuries of dedication, and an unwavering commitment to precision. These blades are a testament to the idea that the instruments of our craft can be as beautiful and meaningful as the art they help create. Their enduring legacy is not just in their physical form, but in the traditions they uphold and the culinary excellence they inspire globally.

From the disciplined forge of the bladesmith to the meticulous hand of the sharpening master, every stage of their creation is imbued with purpose. The diverse types, specialized functions, and unique maintenance requirements all contribute to their distinct identity and superior performance. As we look ahead, the future of these knives promises a fascinating blend of ancient wisdom and modern advancement, ensuring their continued relevance and revered status in kitchens worldwide.

A Synthesis of Form, Function, and Deep-Rooted Heritage

Ultimately, japanese culinary knives represent a magnificent synthesis of form, function, and deep-rooted heritage. Their aesthetic beauty, often understated yet profound, is a direct result of their functional design. Every curve, every bevel, and every finish serves a purpose, whether it’s enhancing cutting performance, ensuring comfort, or protecting the blade. This seamless integration of beauty and utility is a hallmark of Japanese craftsmanship.

The legacy of the samurai sword, the regional specializations, and the philosophical approach to creation all contribute to a heritage that distinguishes these knives from any other. They are not mass-produced commodities but rather works of art, each carrying the story of its maker and its purpose. This rich history adds an intangible value, making each interaction with a Japanese knife a connection to a long lineage of mastery. The ongoing global appreciation of japanese culinary knives is a clear indicator of their irreplaceable position in the culinary world, transcending mere utility to become treasured possessions.

Embracing the Journey: Cultivating a Lifelong Relationship with Your Blade

For those who choose to invest in japanese culinary knives, it marks the beginning of a lifelong relationship—a journey of learning, practice, and appreciation. It’s about more than just buying a tool; it’s about understanding its nuances, respecting its demands, and mastering the art of its care. This cultivation transforms a simple act of food preparation into a mindful, almost meditative, experience.

Learning to sharpen your own blades, understanding the patina of carbon steel, and selecting the perfect knife for each task deepens your connection to the culinary process. It fosters a greater appreciation for the ingredients you work with and the precision you can achieve. Embracing this journey with your japanese culinary knives not only enhances your culinary skills but also enriches your overall experience in the kitchen, turning every cut into a deliberate stroke of artistry. It’s a commitment that pays dividends in both performance and personal satisfaction.

Explore More on Japanese Knives World: